Mechanical specifications – York AFFINITY 292443-XTG-B-0807 User Manual

Page 23

292443-XTG-B-0807

Unitary Products Group

23

TYPICAL WIRING DIAGRAM NOTES

(SEE FIGURE 14)

1.

All field wiring to be accomplished following city, local

and/or national codes in effect at time of installation of

this unit.

2.

Caution: Label all wires prior to disconnection when ser-

vicing controls. Wiring errors can cause improper and

dangerous operation. If any of the wire as supplied with

this unit must be removed it must be replaced with type

105°C, 600V wire or equivalent clearly renumbered for

identification. Verify proper operation after servicing.

3.

Motors inherently protected.

4.

Factory wired for 230V. For 208V operation, move wire

107/PR to 208V. Tap on transformer T1.

5.

See unit nameplate for maximum fuse size and/or circuit

breaker size and minimum circuit ampacity.

6.

If both LR and ASCT are present, wire 801/BL and 805/

BL are connected to ASCT-3. If only LR is present wire

801/BL and 805/BL are connected to M1 coil. If only

ASCT is present wire 202/Y is connected to ASCT-3. If

neither LR or ASCT are present, wire 202/Y is connected

to M1 coil as shown.

7.

Shunt contact also used with crankcase heater.

(optional)

8.

Select indoor blower speed to remain within the temper-

ature rise range on the nameplate in heating.

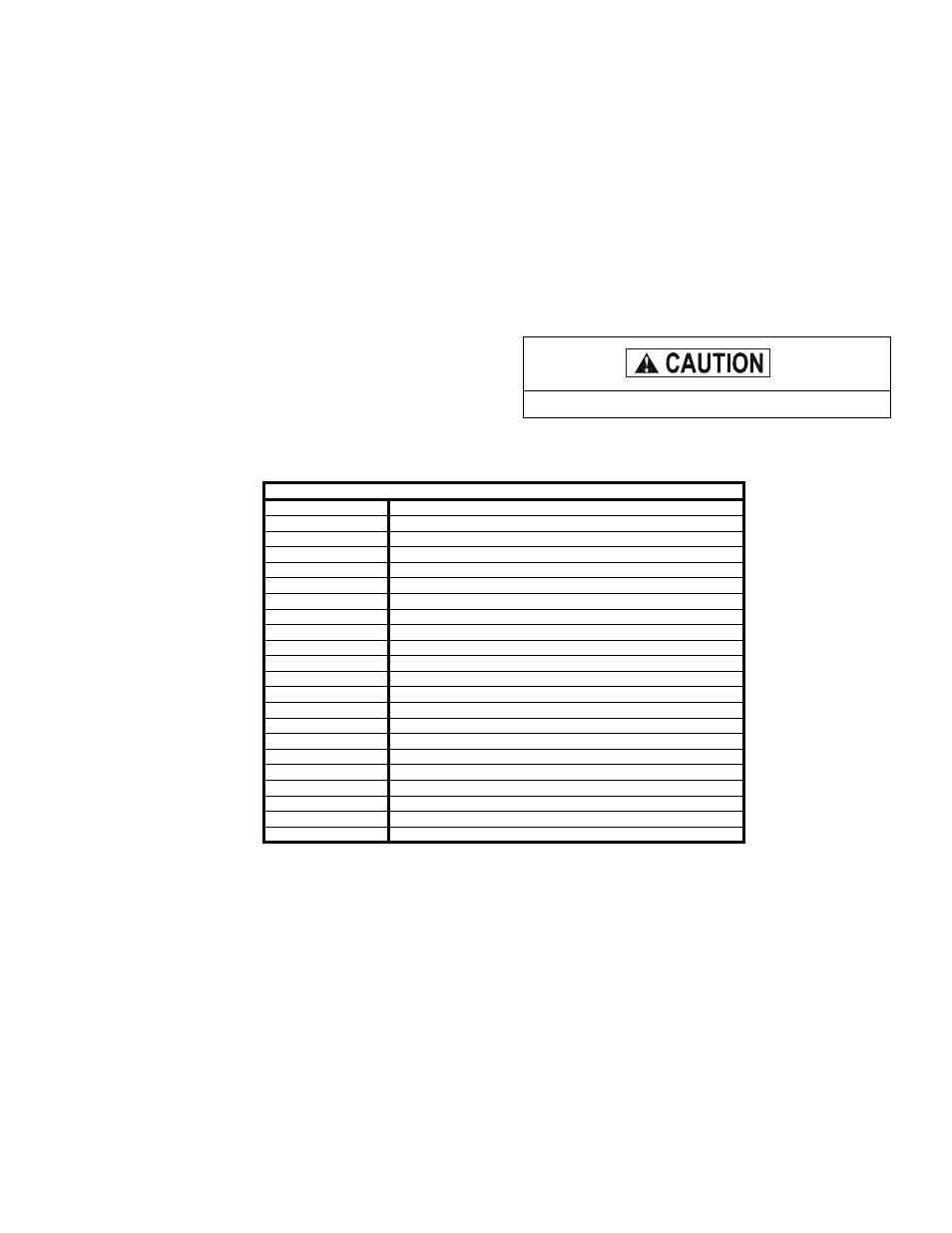

FIGURE 15 - TYPICAL WIRING DIAGRAM LEGEND

MECHANICAL SPECIFICATIONS

GENERAL

Units shall be manufactured by York International Unitary

Products Group in an ISO 9001 certified facility. YORK’s

Affinity™ package units are designed to handle applications

ranging from residential to light commercial and any in

between. The Affinity™ is a unit that gives you the flexibility

and choices you need in today’s market. These packaged

cooling/heating air conditioners are designed for outdoor

installation. Only utility and duct connections are required at

the point of installation. The gas fired heaters have alumi-

nized steel tubular heat exchangers and spark to pilot igni-

tion. They are available in natural gas with field conversion to

propane.

DESCRIPTION

Units shall be factory-assembled, single packaged, Electric

Cooling/Gas Heating units, designed for outdoor mounted

installation. For EER ratings, refer to technical literature.

They shall have built in, equal size, field convertible duct

connections for down discharge supply/return or horizontal

discharge supply/return. The units shall be factory wired,

piped, charged with R-22 refrigerant and factory tested prior

Open all disconnects before servicing this unit.

LEGEND

ALS

AUXILARY LIMIT SWITCH

ASCT

ANTI-SHORT CYCLE TIMER (OPTIONAL)

BR

BLOWER RELAY

CB

CIRCUIT BREAKER

CCH

CRANK CASE HEATER (OPTIONAL)

COMPR

COMPRESSOR

DM

DRAFT MOTOR

FCB

FAN CONTROL BOARD

GND

GROUND

FS

FREEZE STAT SWITCH (OPTIONAL)

HP

HIGH PRESSURE SWITCH OPENS @ 380 PSIG

IDFAN

INDOOR FAN MOTOR

LP

LOW PRESSURE SWITCH OPENS @ 7 PSIG

LS

LIMIT SWITCH

LR

LOCK OUT RELAY (OPTIONAL)

M1

CONTACTOR, COMPR. AND OD FAN

ODFAN

OUTDOOR FAN MOTOR

PS

PRESSURE SWITCH

RC1 / RC2

COMPRESSOR START & OUTDOOR FAN RUN CAPACITOR

RS

ROLLOUT SWITCH

TB4

TERMINAL BLOCK

T1

TRANSFORMER, 24V, 230V