Xerox 110 User Manual

Page 6

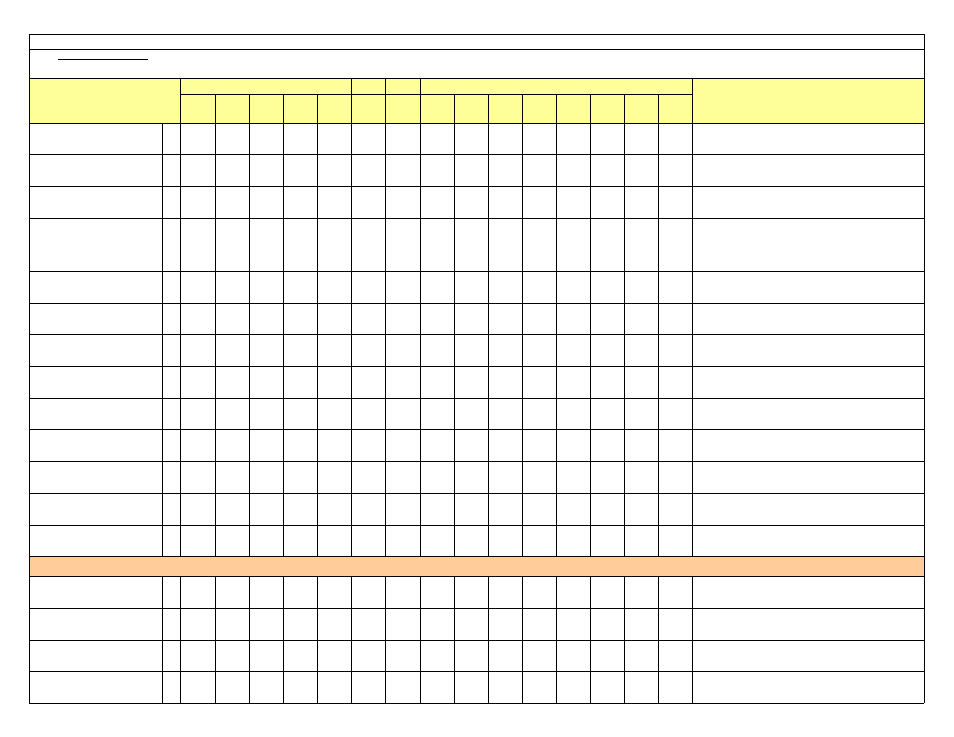

Basis Weight

(lb)

Grammage

Weight (gsm)

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

by Xerox laboratories to guarantee consistent quality.

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

Finish

Sequence

Thickness

(microns)

Weight of the

paper in grams

per square

meter

Sides Coated

Coating Type

Type

Standard cut sizes

Best Practices for Operation

8.5 x 11

8.5 x 14

17 x 11

18 x 12

Other Size

Weight of 500

sheets of the

paper specific

to grade type

Color

Cleanup

XeroxNeverTear

(Xerox Never Tear)

003R3118

180

C2S (Coated

Two Sides)

Gloss

Plain

0

White

119

No

Smooth

Static buildup may affect media runnability and/or stacking.

XeroxNeverTear 3HD

(Xerox Never Tear 3 Hole Drilled)

3 Hole

Drilled

003R3109

180

C2S (Coated

Two Sides)

Gloss

Plain

0

White

119

No

Smooth

Static buildup may affect media runnability and/or stacking.

Stack quality and stack height may be affected due to media structure or high area coverage.

XeroxProColorPBTran

(Xerox Production Color Paper Backed Transparency)

003R5764

180

C1S (Coated

One Side)

Gloss

Transparency

0

Clear

187

No

Smooth

Simplex only recommended.

Stack quality and stack height may be affected due to media structure or high area coverage.

This media may have a mottled appearance due to paper formation (image density and gloss).

Static buildup may affect media runnability and/or stacking.

Deliver to stacker FACE DOWN to avoid stacking issues.

XeroxDocuCard 1up

(Xerox DocuCards 1up)

003R12348

80

200

Uncoated

N/A

Plain

0

White

170

No

Semi-Rough

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

Stack quality and stack height may be affected due to media structure or high area coverage.

For uniform image quality do not image within 5 mm of card edge.

TAB may need to be cleaned prir to running media.

For feeding without a DocuCard Enabler Kit feed tray load max is 50-100 sheets. Load card inboard for Long

Edge Feed and trail edge for Short Edge Feed.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

XeroxWindowDecalsCl

(Xerox Window Decals Clear)

003R06339

200

C1S (Coated

One Side)

Gloss

Transparency

0

Clear

114

No

Smooth

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

Contact Service and implement Tip # 274433 if frequent misfeeds occur.

XeroxWindowDecalsOp

(Xerox Window Decals Opaque)

003R12059

003R12315

200

C1S (Coated

One Side)

Gloss

Transparency

0

Clear

114

No

Smooth

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

XeroxDuraPaper 10pt

(Xerox DuraPaper 10 pt.)

003R12064

003R12063

200

Uncoated

N/A

Plain

0

White

264

No

Regular

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

the latest Customer Maintenance Manual.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

TAB Blade may need to be cleaned during run.

XeroxDuraPaper 3HD

(Xerox DuraPaper-3 Hole Drilled)

3 Hole

Drilled

003R12065

200

Uncoated

N/A

Plain

0

White

264

No

Regular

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

the latest Customer Maintenance Manual.

Stack quality and stack height may be affected due to media structure or high area coverage.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

TAB Blade may need to be cleaned during run.

XeroxCXDocumentFolder

(Xerox Color Xpressions Document Folder)

003R12406

80

216

Uncoated

N/A

Plain

0

White

224

Yes

Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

For uniform image quality, do not image within 5 mm of score.

XeroxGlossGreetCard

(Xerox Glossy Greeting Cards 10pt)

003R6340

219

C1S (Coated

One Side)

High Gloss

Plain

0

White

264

Yes

Smooth

XeroxSGDocumentFolder

(Xerox Supreme Gloss Document Folder)

003R12407

219

C1S (Coated

One Side)

High-Gloss

Plain

0

White

264

Yes

Smooth

For uniform image quality do not imge within 5 mm of the score.

Image degradation may be present on uncoated side (side 2).

XeroxDocuMag C

(Xerox DocuMagnet Coated)

003R12419

280

C1S (Coated

One Side)

Gloss

Plain

0

White

194

No

Smooth

Simplex only recommended

For uniform image quality do not image within 5 mm of card edge.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

XeroxDocuMag U

(Xerox DocuMagnet Uncoated)

003R12418

280

C1S (Coated

One Side)

Matte

Plain

0

White

170

No

Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

Simplex only recommended

For uniform image quality do not image within 5 mm of card edge.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

XeroxLabelDCX M 10up

(Xerox Digital Color Xpressions Matte Coated Labels 10-UP)

003R6332

190

C1S (Coated

One Side)

Matte

Plain

0

White

187

No

Smooth

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

XeroxLabelDCX M 1up

(Xerox Digital Color Xpressions Matte Coated Labels 1-UP)

003R5772

003R12371

190

C1S (Coated

One Side)

Matte

Plain

0

White

187

No

Smooth

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

XeroxLabelDCX M 30up

(Xerox Digital Color Xpressions Matte Coated Labels 30-UP)

003R6333

190

C1S (Coated

One Side)

Matte

Plain

0

White

187

No

Smooth

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

XeroxLabelDCX M 4up

(Xerox Digital Color Xpressions Matte Coated Labels 4-UP)

003R5773

190

C1S (Coated

One Side)

Matte

Plain

0

White

187

No

Smooth

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Label Stock