Xerox 110 User Manual

Page 5

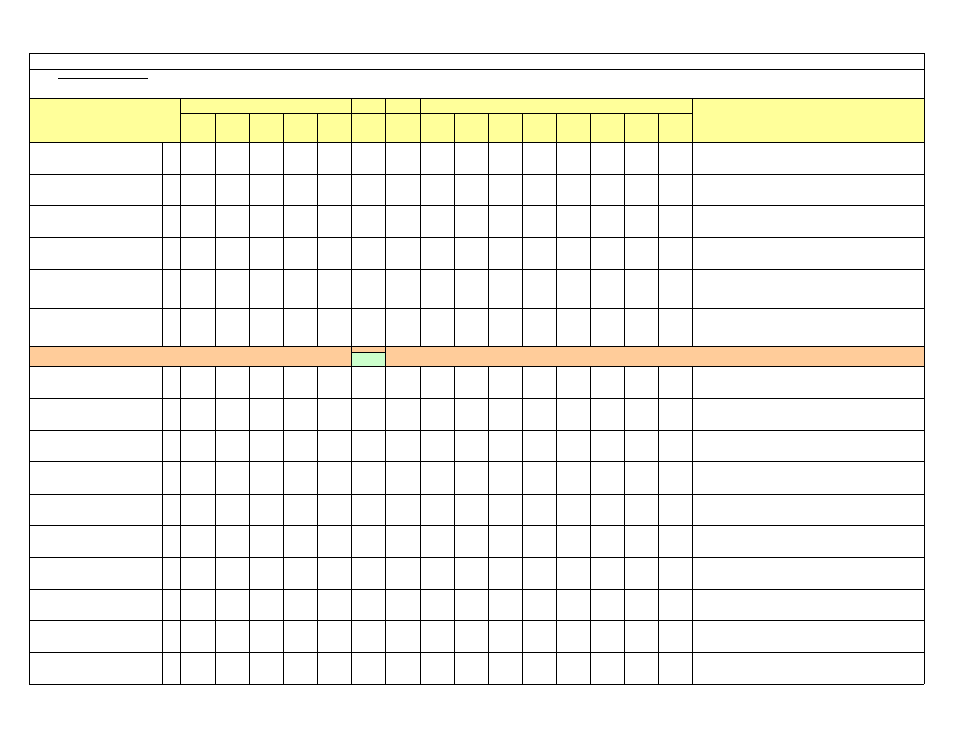

Basis Weight

(lb)

Grammage

Weight (gsm)

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

by Xerox laboratories to guarantee consistent quality.

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

Finish

Sequence

Thickness

(microns)

Weight of the

paper in grams

per square

meter

Sides Coated

Coating Type

Type

Standard cut sizes

Best Practices for Operation

8.5 x 11

8.5 x 14

17 x 11

18 x 12

Other Size

Weight of 500

sheets of the

paper specific

to grade type

Color

Cleanup

XeroxTab 5B Blue3HD

(Xerox Tabs 5 Bank Blue 3 Hole Drilled)

3 Hole

Drilled

003R5313

163

Uncoated

N/A

Precut Tab

5

White

205

No

Regular

Please check with your service representative before running.

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

configuration) is necessary to run tabs or dividers.

XeroxTabS 5B White

(Xerox Tabs Single Straight Collated 5 Bank White)

003R4417

163

Uncoated

N/A

Precut Tab

5

White

205

No

Regular

Please check with your service representative before running.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

configuration) is necessary to run tabs or dividers.

XeroxTabR 5B White3HD

(Xerox Tabs Single Reverse Collated White 3 Hole Drilled)

3 Hole

Drilled

003R4416

163

Uncoated

N/A

Precut Tab

5

White

205

No

Regular

Stack quality and stack height may be affected due to media structure or high area coverage.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

XeroxTabS 5B White3HD

(Xerox Tabs Single Straight Collated 5 Bank White 3 Hole

Drilled)

3 Hole

Drilled

003R4418

163

Uncoated

N/A

Precut Tab

5

White

205

No

Regular

Please check with your service representative before running.

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

configuration) is necessary to run tabs or dividers.

XeroxXpress+Tab 5B 3HD

(Xerox Xpressions+ Tabs 5 Bank 3 Hole Drilled)

3 Hole

Drilled

003R12369

160

Uncoated

N/A

Precut Tab

5

White

170

No

Regular

Stack quality and stack height may be affected due to media structure or high area coverage.

Please check with your service representative before running.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

configuration) is necessary to run tabs or dividers.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

XeroxXpress+Tab 5B

(Xerox Xpressions+ Tabs 5 Bank)

003R12368

160

Uncoated

N/A

Precut Tab

5

White

170

No

Regular

Stack quality and stack height may be affected due to media structure or high area coverage.

Please check with your service representative before running.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

configuration) is necessary to run tabs or dividers.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

Weight (lb.)

XeroxTransferPaper

(Xerox One Step Transfer Paper)

003R5811

003R5812

118

C1S (Coated

One Side)

Gloss

Transparency

0

Clear

143

No

Smooth

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

XeroxCX TriBrochure

(Xerox Color Xpressions Trifold Brochure 32 lb.)

003R12310

32

120

Uncoated

N/A

Plain

0

White

120

No

Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

For uniform image quality, do not image within 5 mm of score.

XeroxPolyPaper 4mil

(Xerox Polyester Paper 4 mil)

003R12414

125

C2S (Coated

Two Sides)

Gloss

Plain

0

White

95

No

Smooth

Static build up may affect media runnability and/or stacking.

XeroxAllinOneMailer

(Xerox All In One Mailer)

003R12446

003R12447

150

Uncoated

N/A

Plain

0

White

160

No

Semi-Rough

This media may have a mottled appearance due to paper formation (image density and gloss).

For uniform image quality, do not image within 3 mm of label edges.

For best image quality do not image within 3 mm of perforations.

ATA mode may improve image quality.

Imaging over die cuts or label edges my adversely affect fuser roll life.

XeroxBRE 1up

(Xerox Business Reply Envelopes 1 up)

003R12445

150

Uncoated

N/A

Plain

0

White

160

No

Semi-Rough

This media may have a mottled appearance due to poor paper formation (image density and gloss).

Stack quality and stack height may be affected due to media structure or high area coverage.

Load and stack 200-300 envelopes maximum due to media structure.

XeroxDocuPac

(Xerox DocuPac Folders)

003R4885

160

Uncoated

N/A

Plain

0

White

215

No

Regular

For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

XeroxPolyPaper 5mil

(Xerox Polyester Paper 5 mil)

003R12363

003R12365

160

Coated Two

Sides

Gloss

Plain

0

White

120

No

Smooth

Static build up may affect media runnability and/or stacking.

XeroxPolyPaper 5mil3HD

(Xerox Polyester Paper 5 mil 3 Hole Drilled)

3 Hole

Drilled

003R12364

160

Coated Two

Sides

Gloss

Plain

0

White

120

No

Smooth

Static build up may affect media runnability and/or stacking.

Stack quality and stack height may be affected due to media structure or high area coverage.

XeroxPremDigBusCard

(Xerox Premium Digital Business Cards 10 Up)

003R12321

163

Uncoated

N/A

Plain

0

White

216

No

Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

For uniform image quality, do not image within 3 mm of card edges (side 1) or within 7 mm of tape edges (side

2).

Stack quality and stack height may be affected due to media structure or high area coverage.

XeroxLaserDocuPac

(Xerox DocuPak Laser Folders)

003R05105

176

Uncoated

N/A

Plain

0

White

178

No

Regular

For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

Specialties