Xerox 110 User Manual

Page 39

Product Description

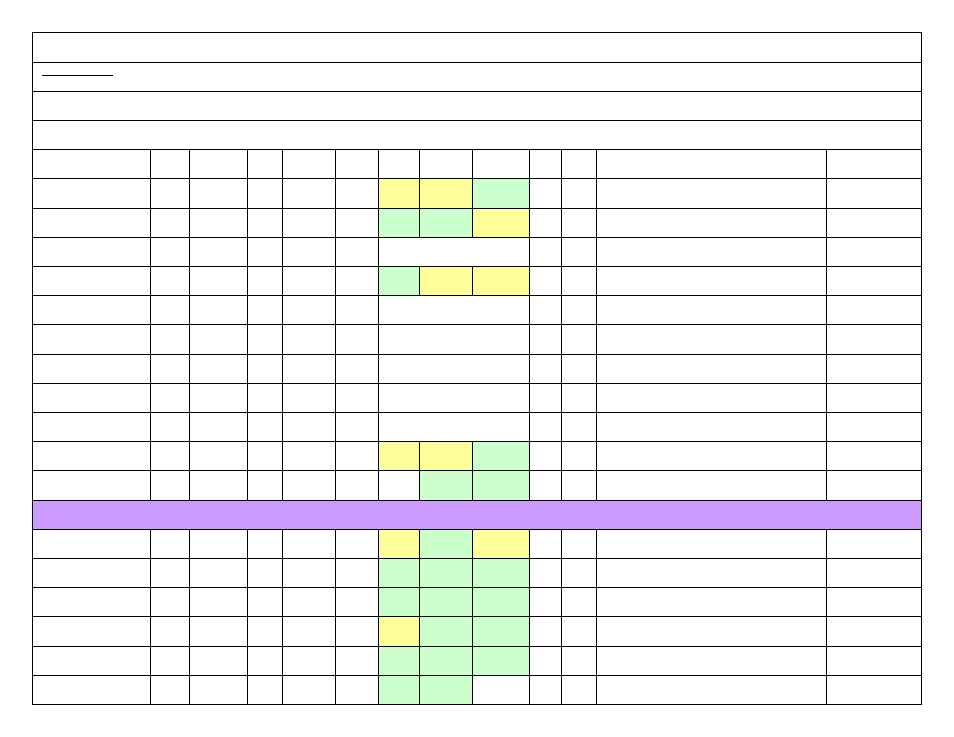

Weight g/m

2

Coating type

Size

Application

Number of

sheets run

Image

Quality

Image

Permanence

Runnability

Auto

Duplex

Date of

test

Notes

Xerox Guaranteed Media

Alternative

Green

- Good test results, purchase a small quantity to insure expectations are met.

Yellow

- Customer should validate the limitations are acceptable for their application. Potential for increased service.

Not Recommended

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Tested Media List February, 2011

The Non-Xerox Tested Media List contains non-Xerox branded paper and specialty media. Xerox has tested many media products on the Xerox iGen4 90/110 Digital Production Press and based on such testing have published this list of tested media products which may or may not, at the time of and based upon such testing, meet Xerox performance criteria. No subsequent

testing has been done and therefore no determination can be made as to whether or not such products would currently fail or pass Xerox performance criteria.

Xerox makes no guarantees or warranties, either expressed or implied, concerning the performance, use, consistency or replacement of non-Xerox branded media or throughput products. Customers should inquire directly of their paper distributor or manufacturer for any guarantees they may offer. When purchasing a

particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met. For guaranteed best performance, use digitally optimized paper and specialty media from Xerox Supplies.

10 mil Tekra vinyl

300

C2S

12x18

50

Yes

Jan-06

odor

Xerox Printable Polyester Papers

Tekra Translite 66000548

300

C2S

14.33 x 22.5

3000

Yes

Mar-06

high static resulting in skew and jams after 100 prints

Xerox Printable Polyester Papers

Koehler synthetic

325

Coated 2 side Gloss

14.33 x 20.5

playing cards

500

Yes

Jul-05

Poor Toner Adhesion

Oil build up on sheets

POTENTIAL SERVICE RISK

Xerox Printable Polyester Papers

Fasson SOS Semi-Gloss Laser S2501

Label Stock

350

C2S Gloss and Semi-

Gloss and C1S Gloss

and Semi-Gloss

8.5 x 11

350

no

Sep-2006

image easily scratched off

Xerox Custom Premium Matte Laser

Label

PVC Tech 310-608-1115

15 mil PVC

350

C2S Gloss

12 x 18

30

yes

10/07

no settings for acceptable image quality

no settings for acceptable toner adhesion

machine fuser roll contamination

Transalloy P-260 EX 0.29 Double White

Matte/Matte

350

C2S Gloss

8.5 x 11

2

no

8/07

Melted in Fuser

Transalloy P-300 0.28 Super China

White M/M

350

C2S Gloss

8.5 x 11

3

no

8/07

Melted in Fuser

Transilwrap 0.023 Polypropylene

350

C2S Gloss

8.5 x 11

30

No

10/07

No settings for acceptable image quality

caliper outside machine specs

DocuStar Magic Stik Label

358

C2S Gloss

12 x 18

50

No

Apr-08

HoloPrisim

8.5 x 11

10

No

Aug-04

EIP mode may be needed for acceptable image permanence.

POTENTIAL SERVICE RISK

Mottle was image quality artifact.

N/A

K&R Plastics 15 pt synthetic paper

397

14 x 20

25

Not

Recommended

No

Feb - '10

Poor solid area coverage that could not be corrected through transfer adjustments.

Xerox 14 mil Polyester Paper

Packaging Paper Board

StoraEnso Tambrite 16 pt.

225

Coated 1 Side

14.33 x 20.5

500

No

Sep-09

Observed jams due to media curl. This media is adversely reactive in extreme environmental

conditions. Edge deletions observed.

Mead WestVaco 16pt.

289

Coated 1 Side

14.33 x 20.5

100

No

Feb - '10

Required use of TransferC to achieve acceptable Image Quality

GP Masterprint 16pt.

290

Coated 1 Side

14 x 22.5

7800

No

Dec - '09

StoraEnso Ensocoat 15 pt.

300

Coated 1 Side

21500

No

Aug-09

Precision 14pt.

306

Coated 2 Side

14 x 20

155

Yes

Jan - '10

Spicer 16pt.

341

Coated 2 Side

14 x 20

230

Not Recommended

No

Jan - '10

Validated feeding problems

Not Recommended

Not Recommended

For best performance it is recommended that these media be stored and run at a relative humidity between 50- 55%

and temperature between 68 - 73 F.

Assure packaging board has adequately acclimated to the conditions in which it is to be printed.

Requires setup to the Xerox Automated Packaging Solution Configuration.

Not Recommended

Not Recommended

Not Recommended

Not Recommended