Installation procedure, Swing joints, Connecting electric control wires – Toro 730 User Manual

Page 2

Installation Procedure _____________________

CAUTION

Golf sprinklers are intended for installation at grade with full

support of the body and piping system from the surrounding

earth. Failure to provide full support may result in premature

failure of the body and/or connecting fittings.

To assure maximum performance from your 734 Series Rotary Sprinklers,

read these instructions completely prior to installation or service.

Swing Joints

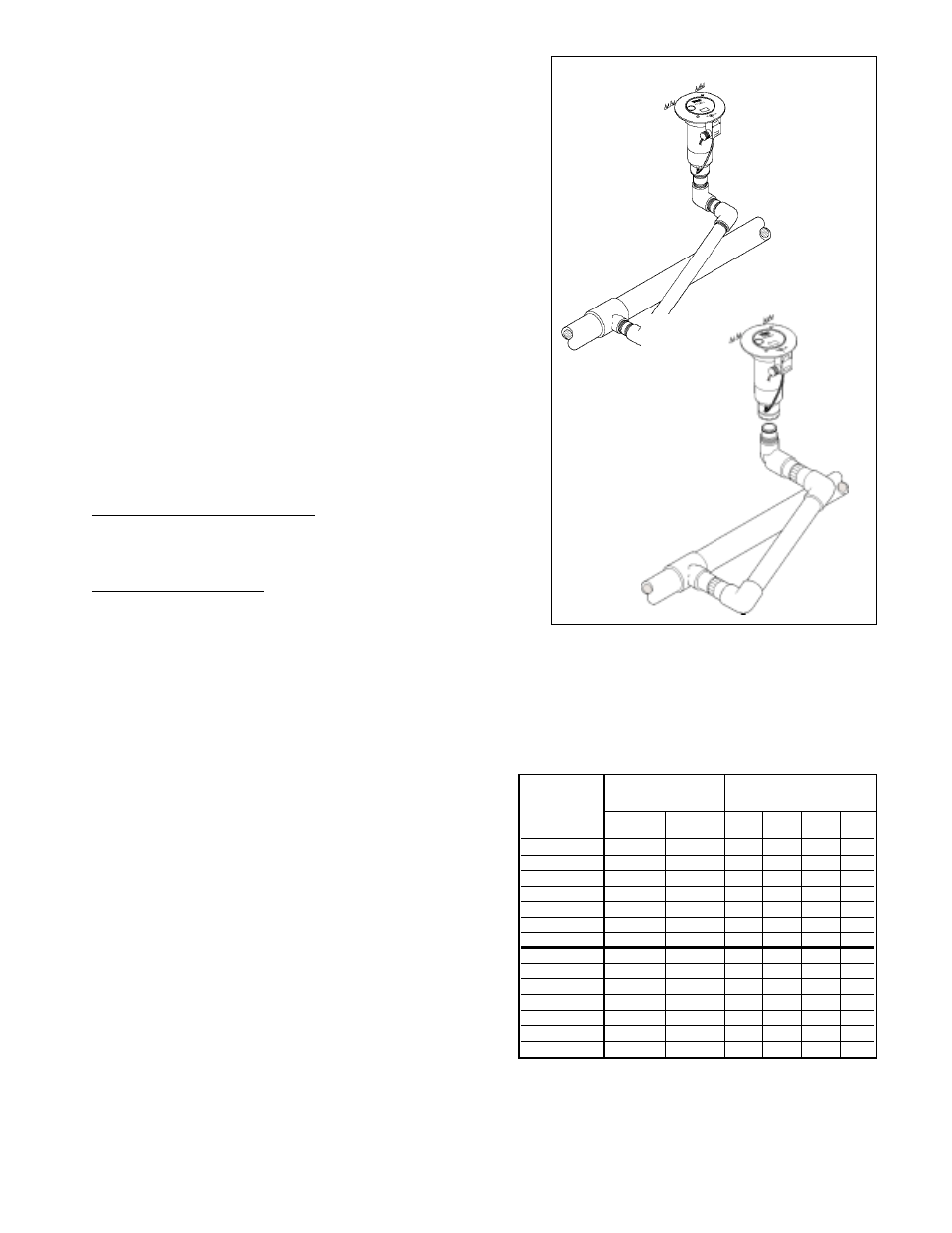

1. Construct or provide triple swing joints for each sprinkler as shown in

Figure 1. Use PVC or ABS pipe nipple for sprinkler connection.

Note: On sites where the possibility of heavy equipment rolling over a

sprinkler exists, the swing joint will flex preventing damage to the

lateral or main lines. On a new installation in raw ground where the

sprinklers are to be initially installed above the finished grade and

lowered when new turf is established, the swing joint allows sprinkler

repositioning without changing risers. This is a common and practical

procedure which eliminates the problem of dirt being accidentally

introduced into the lateral lines when a riser is changed.

2. Flush lines thoroughly prior to installing sprinkler.

3. NPT and BSP Threaded Models

• Apply plumbing tape on riser threads. Install sprinkler onto riser

and tighten.

ACME Threaded Models

• Install ACME threaded bodies onto Acme threaded swing joint

by threading clockwise until hand tight

Note: ACME threaded swing joints have an o-ring that seals to the sprinkle. Plumbing tape is not required..

CAUTION

Use only plumbing tape on riser threads. Use of pipe dope or other types of sealing compounds can cause

deterioration of sprinkler body threads.

Connecting Electric Control Wires

1. Route control wires to sprinkler location(s). Provide enough extra

wire at sprinkler to allow for movement of sprinkler without straining

wire connections. One common wire and station wire is required

for each sprinkler. See Wire Sizing Chart, Table 1 for proper

application.

2. Attach control wires to solenoid leads using an approved

waterproof splicing method.

CAUTION

All wires must be waterproofed to prevent short circuit to

ground and subsequent controller damage.

2

VOLTAGE

WIRE NUMBER

AT

SIZE

OF VALVES

CONTROLLER

CONTROL

COMMON

1

2

3

4

23 V a.c.

14

14

2348

1012

549

353

23 V a.c.

14

12

2890

1239

673

433

23 V a.c.

14

10

3378

1448

786

505

23 V a.c.

12

12

3759

1604

873

561

23 V a.c.

12

10

4591

1973

1071

688

23 V a.c.

12

8

5411

2328

1263

812

23 V a.c.

10

10

5945

2555

1387

892

24 V a.c.

14

14

2765

1309

846

549

24 V a.c.

14

12

3393

1608

1039

673

24 V a.c.

14

10

3962

1877

1213

783

24 V a.c.

12

12

4394

2082

1346

872

24 V a.c.

12

10

5397

2557

1652

1071

24 V a.c.

12

8

6364

3018

1949

1263

24 V a.c.

10

10

6986

3311

2140

1387

Table 1:

Wire Sizing Chart

Maximum allowable length in feet from controller to electric VIH

sprinklers.

OUTPUT

VOLTAGE AT

CONTROLLER

TRANSFORMER

Figure 1: Triple Swing Joints

(NPT & BSP

models only)

(ACME

models only)

NOTE: Minimum solenoid voltage required for reliable electric

VIH operation is 20 V a.c.

Chart based on the following

Transformer - 115/230 V a.c. - 24 V a.c., 45 VA

Coil Assy.

- 24 Va.c., 60 Hz

Holding

- .30 Amps

In Rush

- .40 Amps