3 chapter 4 – The Eltron Company P310 User Manual

Page 55

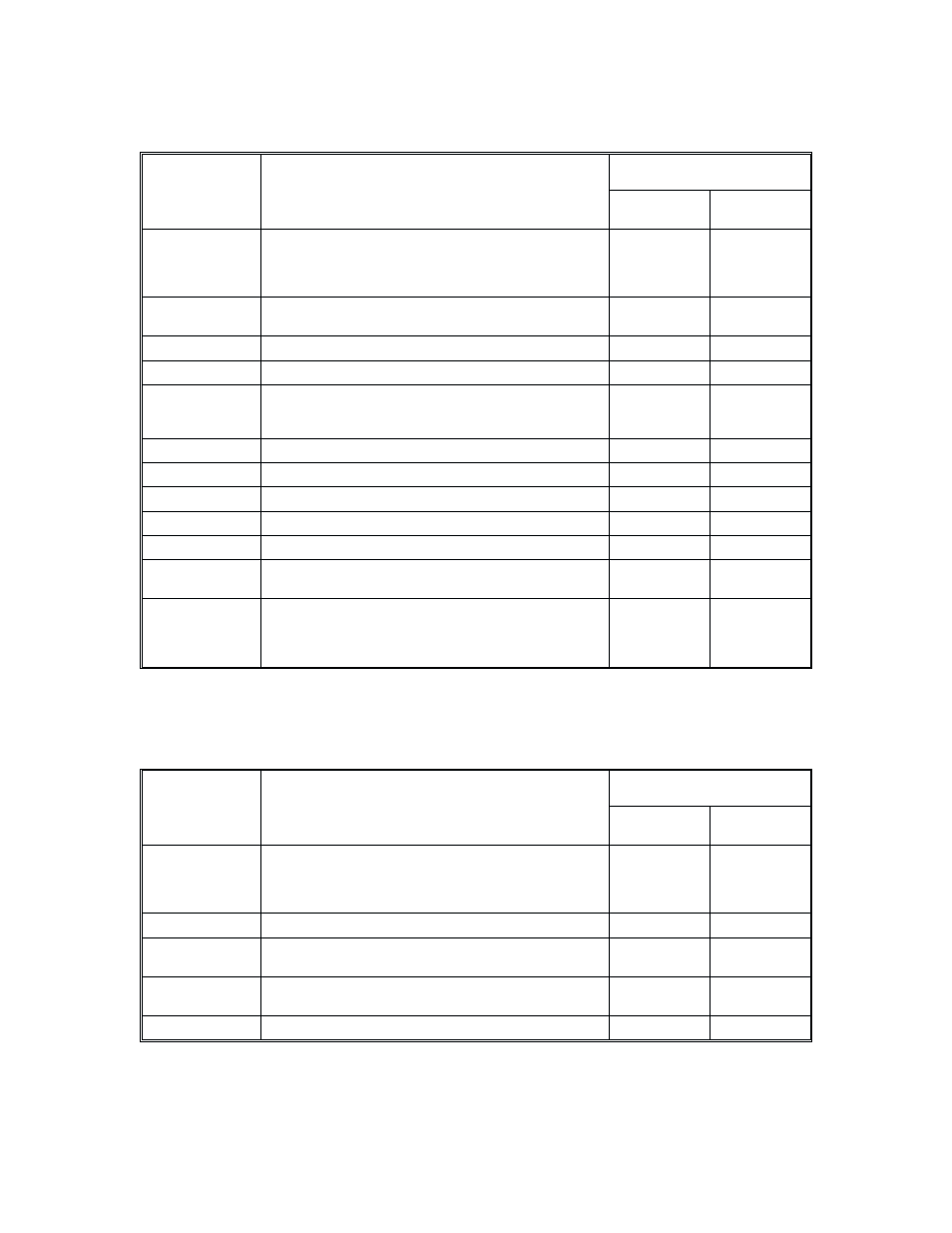

Problems Associated with Print Anomalies

Symptom

Possible Causes

References

Adjustment

or Cleaning

Replace-

ment

No Image

Non Eltron Ribbon Installed Upside Down

CPU Board

Head Up/Dn Motor

Head Position Sensors

2.2.4

5.2.10

5.2.16

5.2.12

Faint Image

Low Print Head Voltage

Dirty Print Head

6.2.2

5.2.10

Artifacts

Particles on Feed or Transport Rollers

2.2.7, 6.2.1

Horizontal Lines

Dirty or Damaged Print Head Element

2.2.7, 6.2.2

5.2.6

Multiple

Evenly-Spaced

Horizontal Lines

CPU Board Print Head Registers

5.2.10

Vertical Lines

Stepper Transport Belts Too Tight

6.3.1

Sticking Ribbon

Peel Bar Adjustment

6.3.3

Washout

Peel Bar Adjustment

6.3.3

Sheared Ribbon

Image Not Centered

6.3.2

Image Off Center

X- and Y-Offset Values

6.3.2

CMYK Not

Aligned

Erratic Card Feed due to Belt Tension or dirty rollers

2.2.7, 6.2.1,

6.3.1

Abrupt Color

Change

Initialization/Ribbon Sensor/Proper Ribbon

Flag Sensor

Clutch Pads

Ribbon Take-Up Motor/O-Ring

2.2.4

5.2.8

5.2.13

5.2.17

5.2.14

Problems Associated with Card Transport Failures

Symptom

Possible Causes

References

Adjustment

or Cleaning

Replace-

ment

No Card Feed

Card Gate Adjustment

Dirty Card Feed Roller

Card-Feed Motor

Card-Feed Belt

2.2.5

2.1.5~2.1.7

5.2.16

5.2.16

Multiple Card Jam Card Gate Adjustment

2.2.5

Partial Card Feed

Card Transport Belt

Card Sensor

5.2.9, 5.2.14

Stall near Cleaning

Roller

Card Sensor

Rear Card Transport Belt

5.2.14

Stall Past Platen

Front Card Transport Belt

5.2.9

980264-001 Rev. B

4-3

CHAPTER 4