Maintenance, Trouble-shooting tips – Outback Power Systems Hitch DOM-OBK03 User Manual

Page 17

GPS IM

PLEMENT GUIDAN

CE

®

15

MAINTENANCE

Proper maintenance of the Outback® Hitch mechanical

components will ensure years of dependable service and

protect your investment.

Initial Installation: After the first few hours of operation,

check the tightness of all Hitch mounting bolts and hard-

ware. Substantial wear will occur to the Hitch and tractor

drawbar if mounting bolts are not properly tensioned.

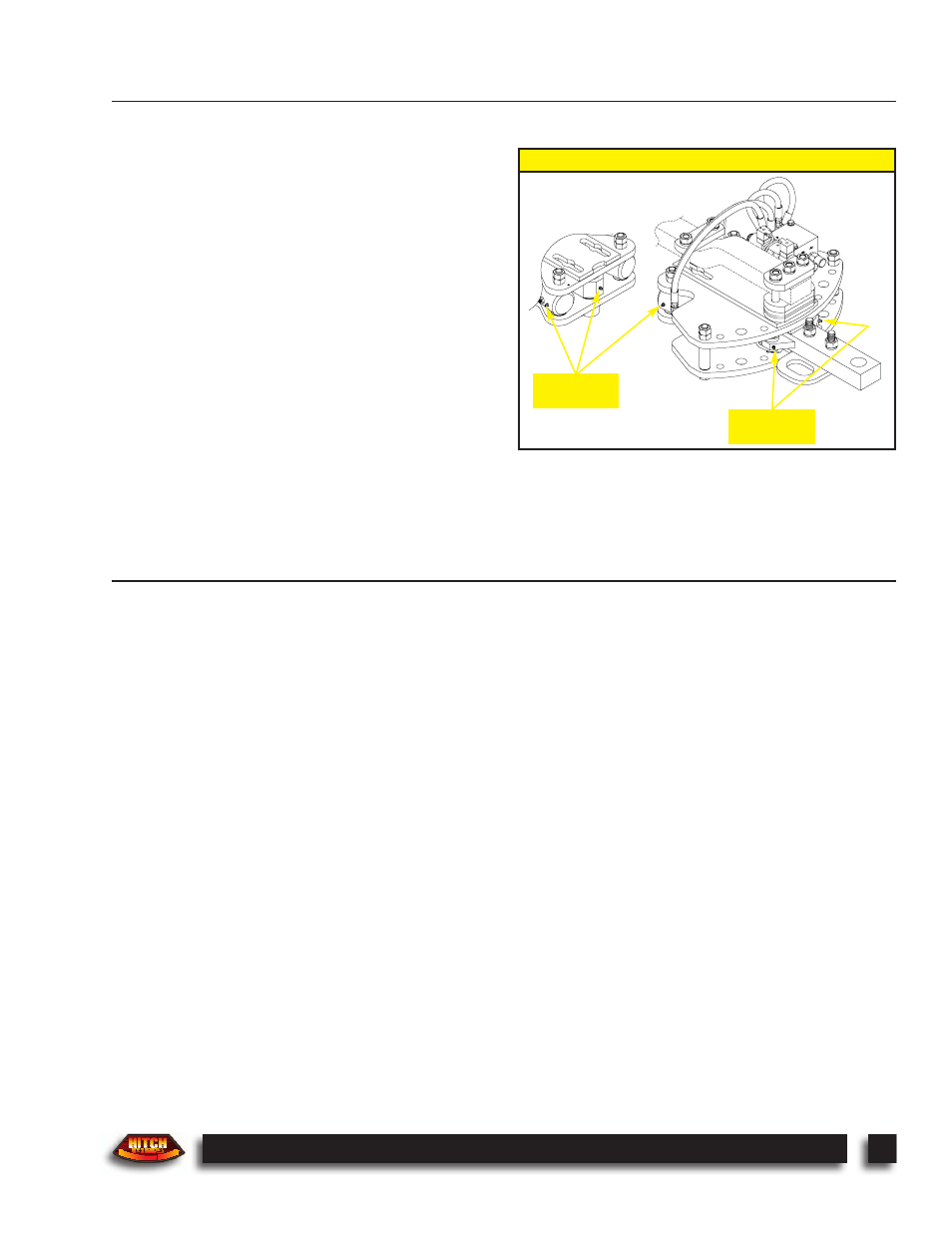

Grease Fittings: Proper lubrication of the 5 grease loca-

tions at 12-hour intervals will dramatically prolong the life

of friction production parts. Use an SAE multi-purpose

type grease. Make sure to clean the fittings thoroughly

before using any grease gun.

Replace Worn Components: At the begining of each

application season, check the hitch drawbar for any signs

of free-play, both up and down and side to side. All wear

points of the Hitch include serviceable replacement parts.

Refer to pages A4 and A5 for details.

TROUBLE-SHOOTING TIPS

12 Hours

(3 Places)

12 Hours

(2 Places)

GREASE LOCATIONS

Problem - Probable Cause. Action

Hitch Drawbar Doesn’t Move

√ Tractor Hydraulics Not Active. Make sure hydraulic hoses are hooked up correctly (red hand grip to pressure;

black hand grip to return). Use push button over-rides on hydraulic block coils to verify operation.

√ Poor Electrical Connection. Check the indicator lights on the hydraulic block coil connectors. If no lights,

check cable connections. If lights show, then replace coil.

Hitch Drawbar Moves in the Wrong Direction

√ Tractor Hydraulics Reversed. Make sure hydraulic hoses are hooked up correctly (red hand grip to pressure;

black hand grip to return).