Loading sheet material – Roland FJ-42 User Manual

Page 23

21

2 Basic Operation

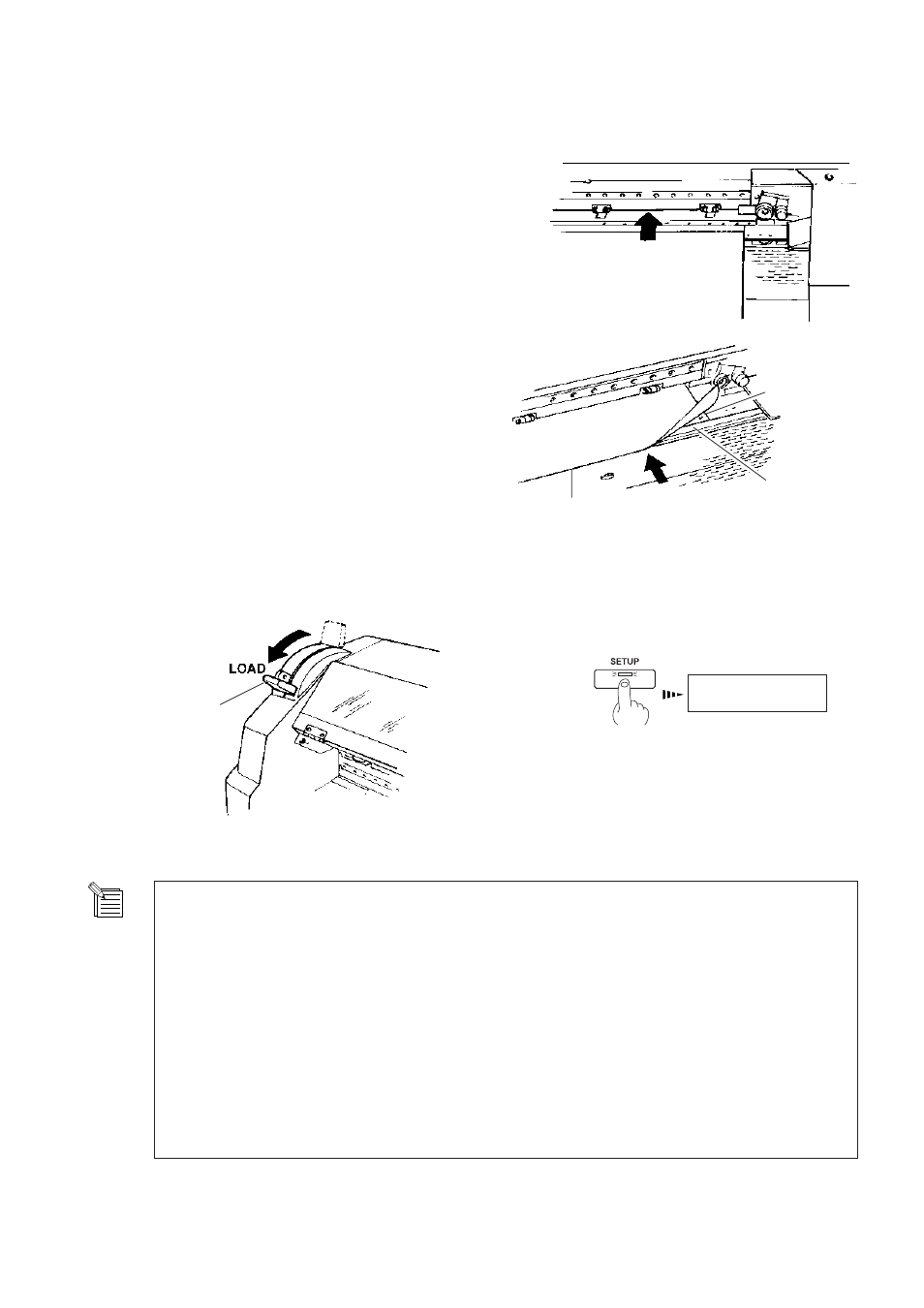

Pass the material between the pinch rollers and the grit

rollers as shown in the figure.

1

Line up the right-hand side of the material with the

guide line, and line up the front edge of the material

with the reflective tape.

If the front edge of the material has been cut at an

angle, pull out the material so that all of the material

covers the reflective tape.

* Be sure to line up the right-hand edge of the material

with the guide line.

If the material is not positioned correctly when the

[SETUP] key is pressed, the display shows "IN-

VALID SHEET SET SHEET AGAIN."

2

Loading Sheet Material

Move the sheet loading lever toward LOAD.

The pinch rollers lower to hold the material in place.

3

Close the front cover, and press the [SETUP] key.

This detects the width of the material and displays the

printable width.

4

W 300 mm

FINE BI-DIR

Top menu

The SETUP LED lights up

Front

Front edge of the material

Reflective tape

Guide line

Front

Sheet loading lever

Sheet Material

- When using sheet material, if the loaded material contacts the media flange of the back of the unit, shift the right-

hand retainer to a position where the material doesn't touch the media flange.

- When transparent material is loaded, it is necessary to set [SHEET TYPE] to [CLEAR]. For more information, see

"4-6 What to Do If..." (Even when the [SETUP] key is pressed, [INVALID SHEET] appears and the material

cannot be detected).

- When thick material is loaded, it may adjust the head height. For more information, see "4-2 Adjusting the Height

of the Printing Head."

- When changed to a different type of material, it is necessary to carry out feed correction and bidirectional correc-

tion. For more information, see "2-6 Printing -- Making Corrections for Printing."

- If the sides of the material have warped, then bend back the warp or feed the warped portion to the front and

perform setup again. Attempting to print with warped material may scrape the printing heads or cause the material

to jam. If the printing heads become damaged or soiled as a result, printing accuracy may suffer.