Inspection procedures – Raypak RAYTHERM 0135B User Manual

Page 31

31

Inspection Procedures

Burners

Clean main burners and air louvers of dust, lint and

debris. Keep boiler area clear and free from com-

bustibles and flammable liquids. Do not obstruct the

flow of combustion and ventilation air. Make visual

check of burner and pilot flame. Yellow flame indicates

clogging of air openings. Lifting or blowing flame indi-

cates high gas pressure. Low flame indicates low gas

pressure.

Inspection Schedule

To be performed the first and third month after initial

start up and then on an annual basis. If problems are

found, refer to Troubleshooting Guide for additional

directions.

1. Remove top of boiler and inspect heat exchanger

for soot and examine venting system.

2. Remove rear header and inspect for scale

deposits.

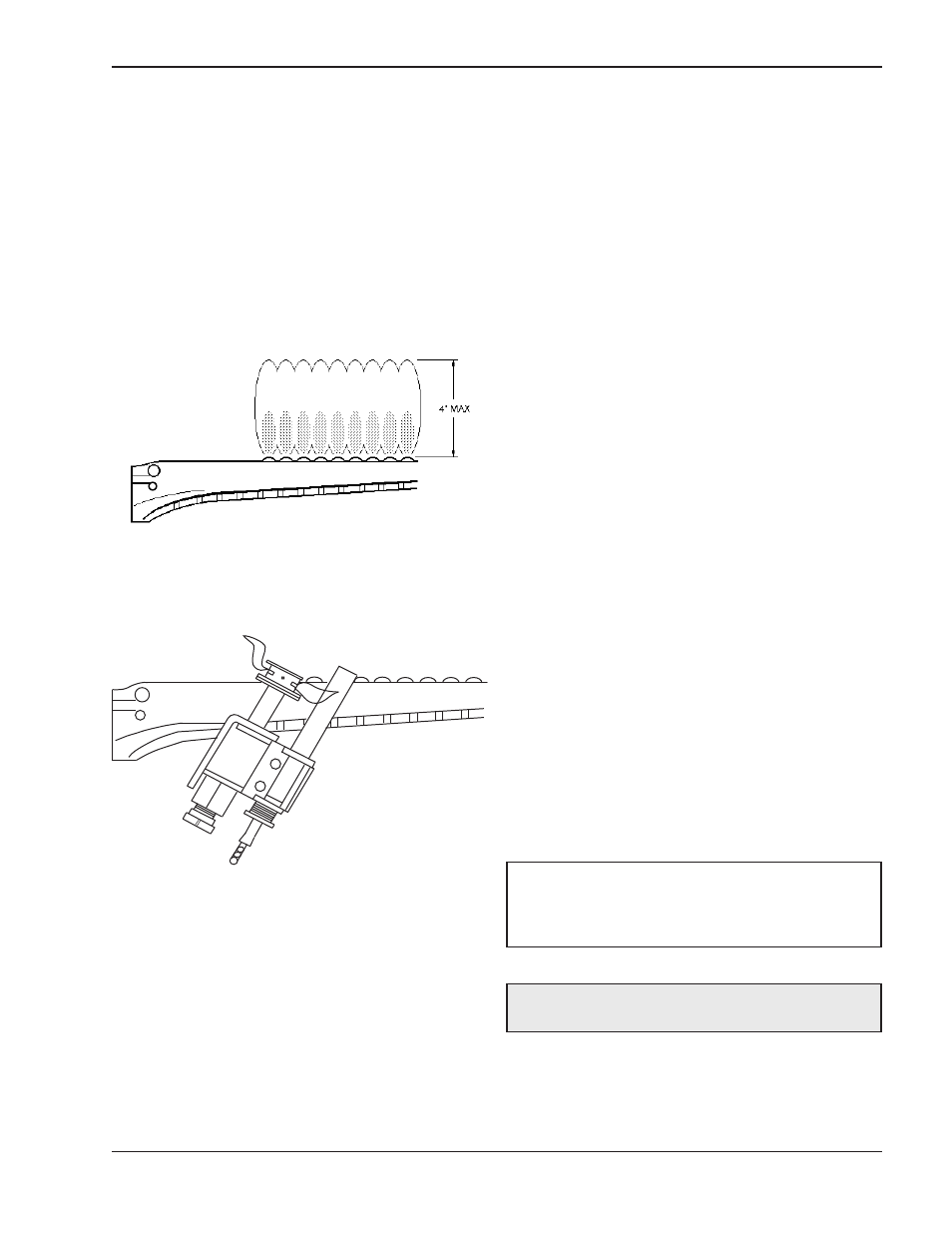

Fig. 33: Main Burner Flame

NOTE: Modulating burner flame varies in height from approximately

1/4" at low fire to approximately 4" in high fire.

Fig. 34: Pilot Burner Flame (Standing Pilot Units)

*3. Inspect pilot and main burner flame and firing rate.

*4. Inspect and operate all controls and gas valve.

*5. Visually inspect system for water leaks.

*6. Inspect oil pump motor and bearing assembly, if oil

cups are provided.

7. Check flow switch paddle.

8. Clean room air intake openings to ensure ade-

quate flow of combustion and ventilation air.

9. Keep boiler area clear and free from combustible

materials, gasoline, and other flammable vapors

and liquids.

*Should be checked monthly. (Takes approximately 15

minutes).

Low Water Cut-Off (When Installed)

The low water cut-off automatically shuts down burner

whenever water level drops below probe. 90 second

time delay prevents premature lockout due to tempo-

rary conditions such as power failure or air pockets.

Flush float type devices at beginning of each heating

season.

Procedure for Cleaning Flue Gas

Passageways

Soot will clog areas behind fins and eventually cause

tube failure. Any sign of soot at base of burners or

around outer jacket indicates a need for cleaning.

1. Lift off drafthood and flue collector by removing

bolts and screws.

2. Remove "V" baffles from heat exchanger.

3. Remove burner tray, see Burner Tray Removal.

4. Take garden hose and wash heat exchanger, mak-

ing sure soot is removed from between fins. (Avoid

excessive water against refractory).

5. Reassemble; when boiler is fired, some steam will

form from wet refractory. This is normal.

NOTE: In extreme cases it may be necessary to

remove the heat exchanger completely for cleaning.

The simplest method is steam cleaning at a local car

wash. DO NOT WIRE BRUSH!

CAUTION: Soot is combustible, so exercise

extreme care.