Servicing procedures, Sequence of operation, General location of controls – Raypak RAYTHERM 0135B User Manual

Page 26: Intermittent ignition device (iid)

26

SERVICING

PROCEDURES

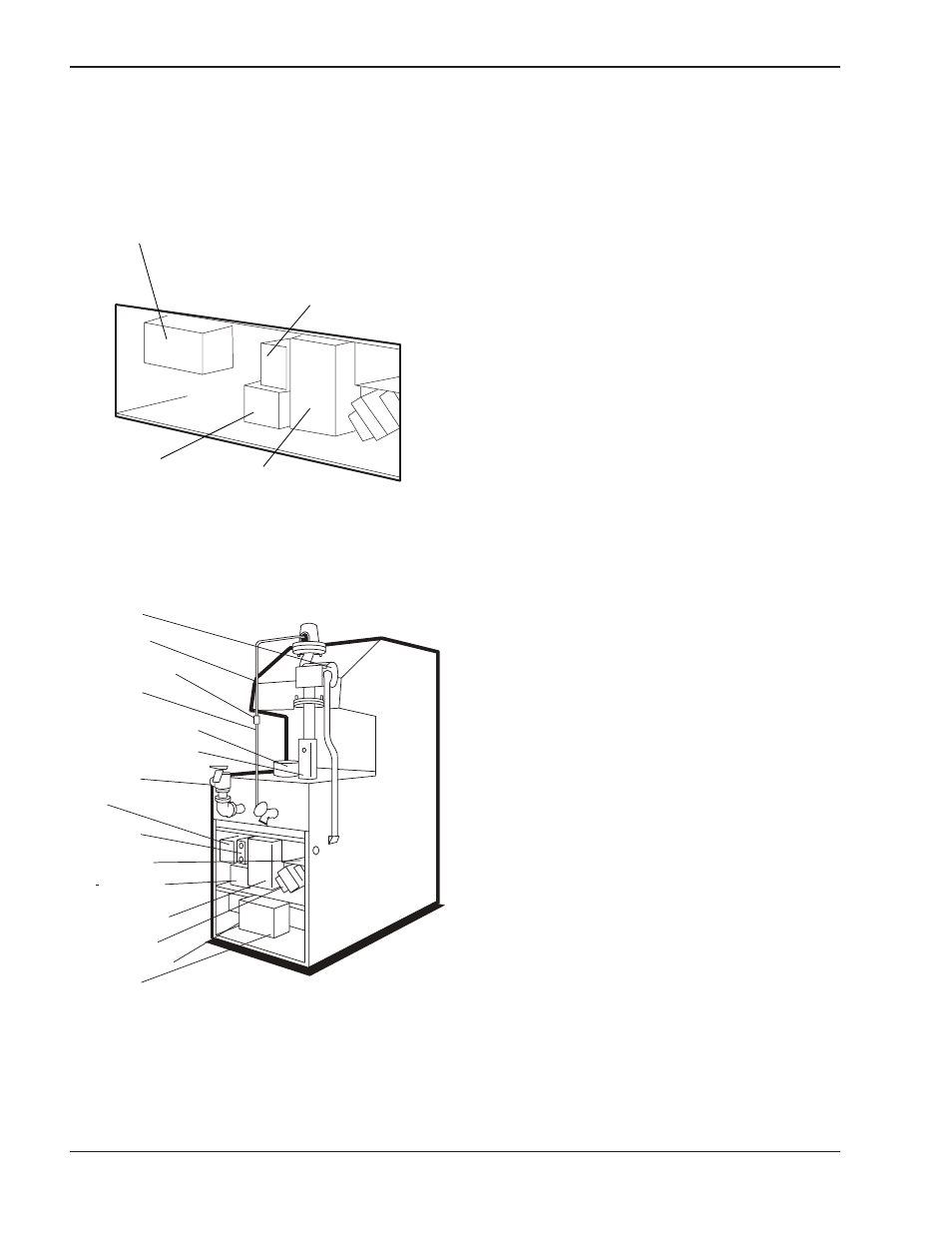

General Location of Controls

Fast-

Response

Temperature

Sensor

2-Stage Controller

Relay

Ignition Module

(Auto Ignition Only)

Fig. 25: Control Box Component Locations

Models 135 & 180

CIRCULATOR

VENT SENSOR

BYPASS VALVE

(MODELS 135 & 180 ONLY)

BYPASS LINE

TEMPERATURE

AND PRESSURE GAUGE

2-STAGED CONTROLLER

(MODEL 90 ONLY)

PRESSURE

RELIEF VALVE

RELAY

ADJUSTABLE

HIGH LIMIT

FIELD WIRING

COMPARTMENT

FAST RESPONSE

TEMPERATURE SENSOR

IGNITION MODULE

(AUTO IGNITION ONLY)

TRANSFORMER

ROLL-OUT SENSOR

GAS VALVE

Fig. 26: Component Locations

SEQUENCE OF

OPERATION

Intermittent Ignition Device

(IID)

Boilers equipped with the IID system will automatical-

ly light the pilot burner first and then the main burner,

each time there is a call for heat from the room ther-

mostat. Whenever the room thermostat is calling for

heat, the circulator supplied with the boiler will be

energized and should be running.

The ignition control module will also be energized to

initiate the pilot ignition by opening the first main valve

(pilot). At the same time, the electronic spark genera-

tor in the module produces a high-voltage spark output

that lights the pilot burner. If the pilot burner does not

light, the module will not energize the second main

valve and the burners will not light.

Ignition spark continues only until the timed trial for

ignition period ends. Then, the module goes into safe-

ty shutdown or lockout. Lockout de-energizes the first

main valve operator and closes the first main (pilot)

valve in the gas control, stopping pilot gas flow. The

ignition control system must be reset by setting the

thermostat below room temperature for one minute or

by turning off power to the module for one minute.

When the pilot flame is established, flame rectification

circuit is completed between the sensor and burner

ground. The flame sensing circuit in the module

detects the flame current, shuts off the spark genera-

tor and energizes the second main valve operator

which opens the second main valve. This allows gas to

flow to the burners where it is ignited by the pilot burn-

er flame.

When the thermostat is satisfied, the valve operators

are de-energized shutting off the pilot and main burn-

ers, and also the circulator.