Spark plug, Lubricating the bar tip sprocket, Needle bearing lubrication – RedMax GZ7000 User Manual

Page 35: Adjustment of the oil pump, Maintenance

MAINTENANCE

English

–

35

The filter can be cleaned more thoroughly by washing it in

water and detergent.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced.

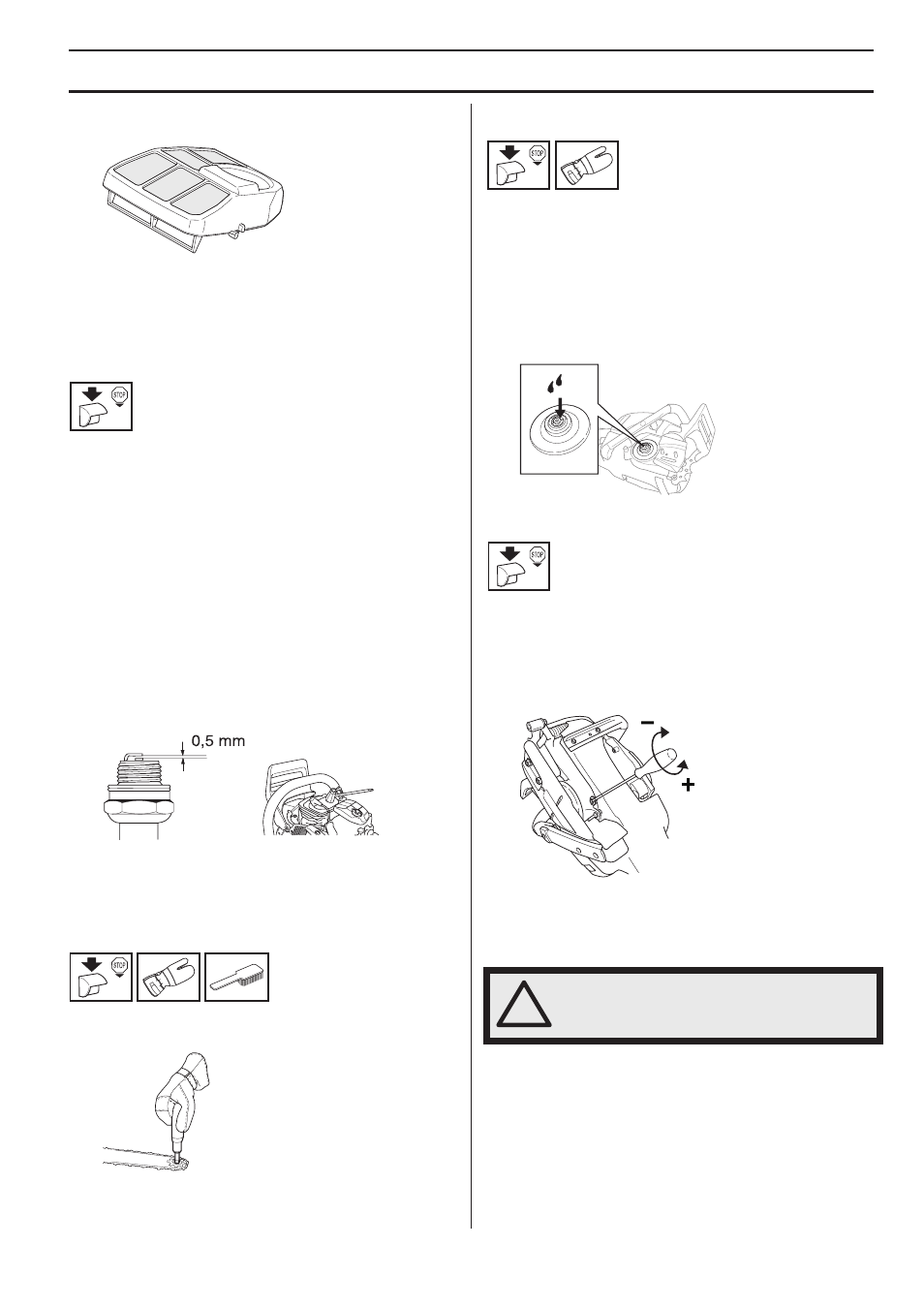

Spark plug

The spark plug condition is influenced by:

•

Incorrect carburetor adjustment.

•

An incorrect fuel mixture (too much or incorrect type

of oil).

•

A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0.020 inch (0.5

mm). The spark plug should be replaced after about a

month in operation or earlier if necessary.

Note! Always use the recommended spark plug type! Use

of the wrong spark plug can damage the piston/cylinder.

Check that the spark plug is fitted with a suppressor.

Lubricating the bar tip sprocket

Lubricate the bar tip sprocket each time you refuel. Use

the special grease gun and a good quality bearing grease.

Needle bearing lubrication

The clutch drum has a needle bearing on the output shaft.

This needle bearing must be lubricated regularly (once a

week).

When lubricating, remove the clutch cover by loosening

the two bar nuts. Lay the saw on its side with the clutch

drum upwards.

Lubrication involves engine oil dripping into the centre of

the clutch drum as it rotates.

Adjustment of the oil pump

The oil pump is adjustable. Adjustments are made by

turning the screw using a screwdriver or combination

spanner. The machine is supplied from the factory set to

1 turn open. Turning the screw clockwise will reduce the

oil flow and turning the screw anti-clockwise will increase

the oil flow.

Recommended settings:

Bar 20"-24":

2 turns from the closed position.

Bar 28" - :

3 turns from the closed position.

!

WARNING! The engine must be stopped

when making adjustments.