87%-efficiency boilers – special instructions – Raypak Hi Delta 992B-1262B User Manual

Page 45

45

87%-Efficiency Boilers –

Special Instructions

Water Piping

An 87%-efficiency boiler requires a minimum inlet

water temperature of 120ºF (49ºC) to prevent exces-

sive condensation in the combustion chamber. An

87%-efficiency boiler operated with an inlet tempera-

ture of less than 120ºF (49ºC) must have a manual

bypass or an approved low-temperature operation

system to prevent problems with condensation. A man-

ual bypass, shown in Fig. 15, must be piped into the

system at the time of installation. This piping is like a

primary/secondary boiler installation with a bypass in

the secondary boiler piping. Raypak strongly recomm-

NOTE: The constructions of the 84%- (standard)

and 87%-efficiency (optional) boilers are very similar,

and they are installed to the same requirements,

except as noted in this section.

ends that a thermometer be placed into the boiler inlet

piping next to the in/out header to facilitate tempera-

ture adjustment. Inlet water temperatures below 120ºF

(49ºC) can excessively cool the products of combus-

tion, resulting in condensation on the heat exchanger.

Venting

Appliance Categories

See Table P for appliance category requirements for

the 87%-efficiency Hi Delta.

CAUTION: Proper installation of flue venting is criti-

cal for the safe and efficient operation of the boiler.

NOTE: For additional information on appliance

categorization, see appropriate code NFGC (U.S.)

and B149 (Canada), or applicable local building

codes.

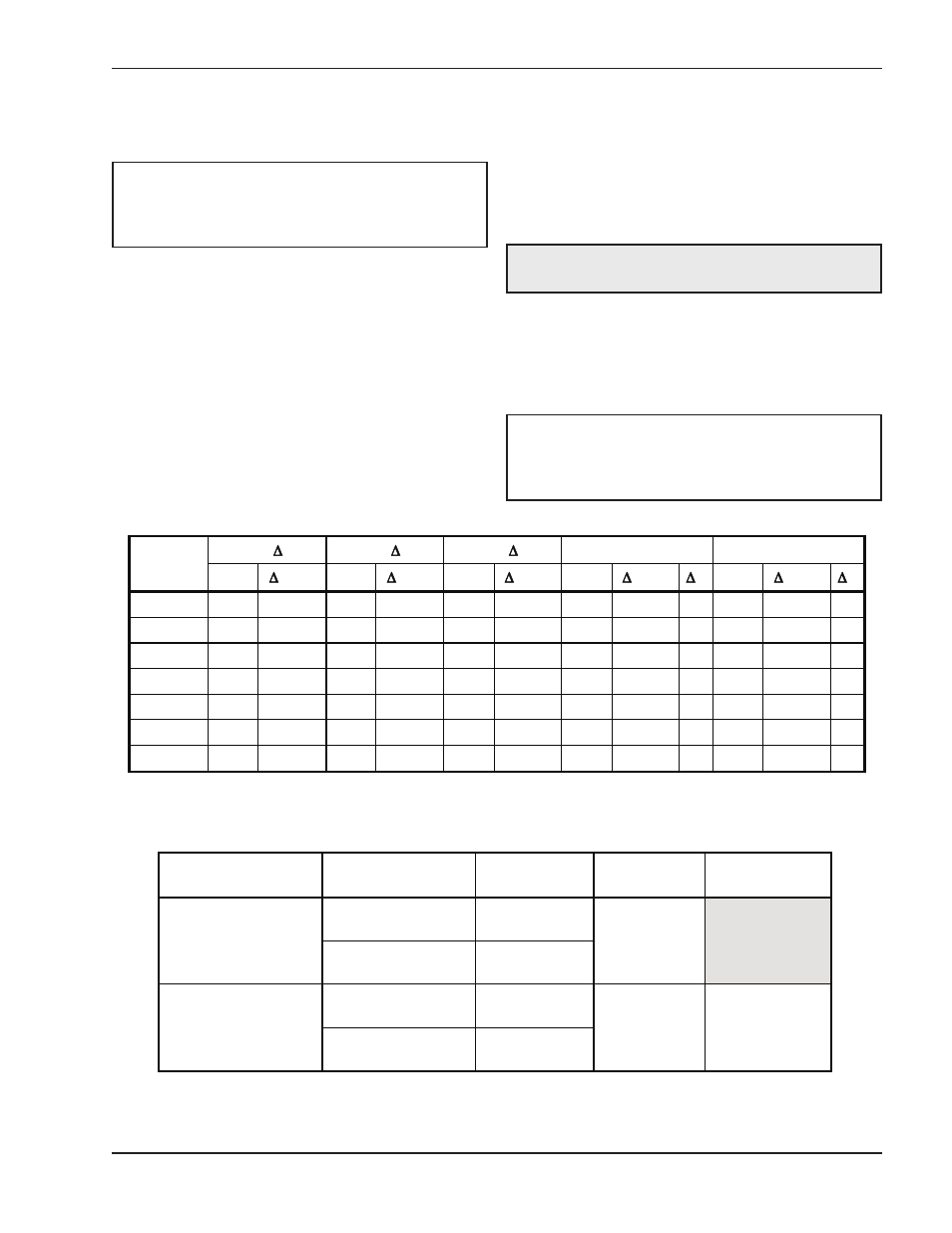

20°F T

30°F T

40°F T

Min. Flow

Max Flow

Model

No.

gpm

P (ft)

gpm

P (ft)

gpm

P (ft)

gpm

P (ft)

T

gpm

P (ft)

T

992BE

86

5.6

57

2.5

43

1.4

43

1.4

40

132

13.1

13

1262BE

110

10.3

73

4.6

55

2.6

55

2.6

40

132

14.8

17

1532BE

132

16.5

89

7.6

67

4.3

67

4.3

40

132

16.5

20

1802BE

N/A

N/A

104

11.5

78

6.5

78

6.5

40

132

18.3

24

2002BE

N/A

N/A

116

14.8

87

8.5

87

8.5

40

132

19.0

26

2072BE

N/A

N/A

120

15.8

90

9.1

90

9.1

40

132

19.0

27

2342BE

N/A

N/A

N/A

N/A

102

12.9

102

12.9

40

132

21.4

31

Combustion

Air Supply

Exhaust

Configuration

Heater Venting

Category

Certified

Materials

Combustion Air

Inlet Material

Vertical Natural Draft

Venting

II

From Inside Building

(Non-Direct Venting)

Horizontal Through-

the-Wall Venting

IV

AL29-4C

Stainless Steel

(Gas Tight)

Vertical Natural Draft

Venting

II

From Outside Building

(Direct Venting)

Horizontal Through-

the-Wall Venting

IV

AL29-4C

Stainless Steel

(Gas Tight)

Galvanized Steel

PVC

ABS

CPVC

Table O: Heater Rate of Flow and Pressure Drop

Table P: Category Determination for Venting Purpose and Venting Arrangement

Note: Basis for minimum flow is 40°F ΔT. Basis for maximum flow is 132 gpm.