Inspections – Raypak RAYTHERM 0133-4001 User Manual

Page 29

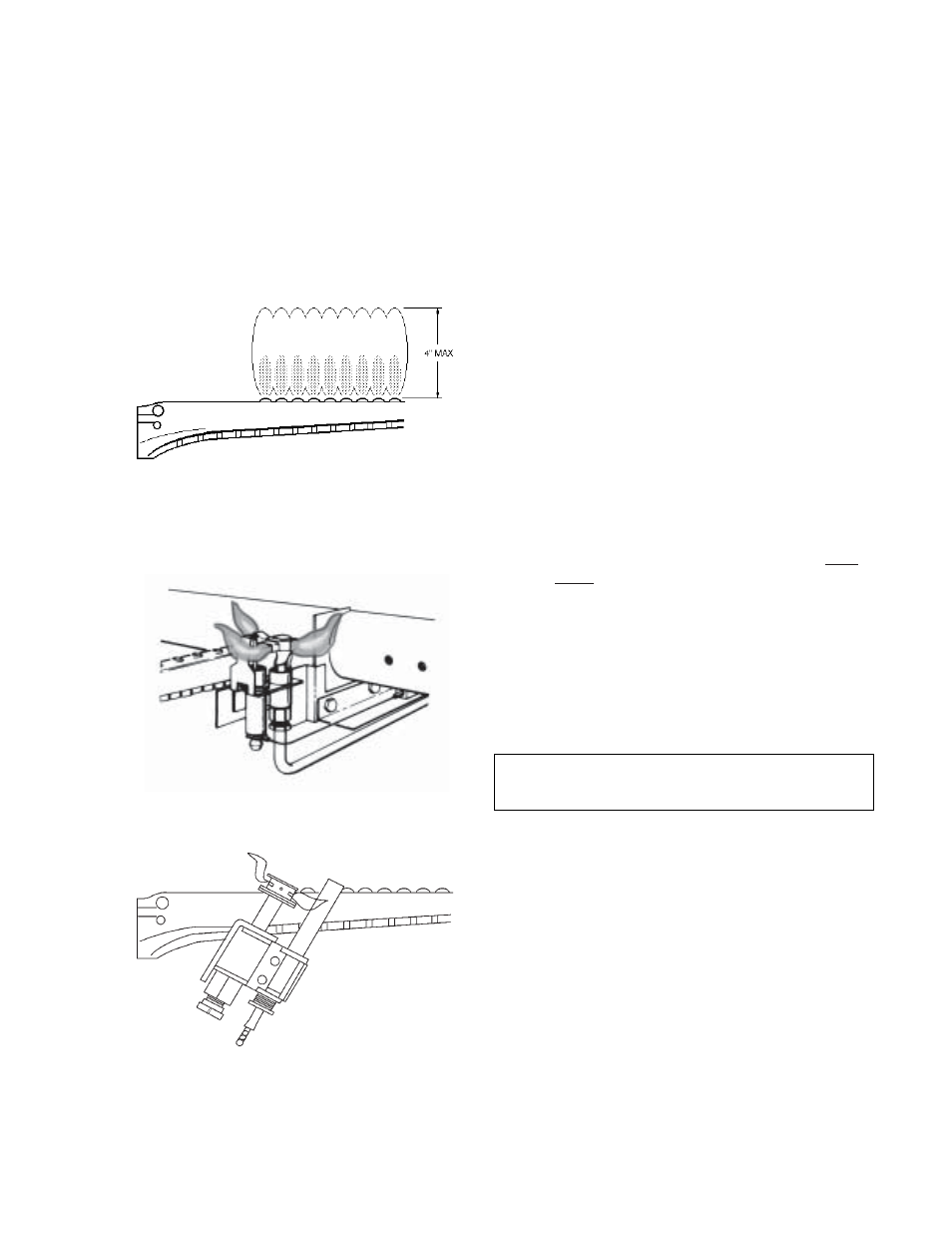

PILOT BURNER FLAME (IID UNITS)

INSPECTIONS

BURNERS

Clean main burners and air louvers of dust, lint and

debris. Keep boiler area clear and free from com-

bustibles and flammable liquids. Do not obstruct the

flow of combustion and ventilation air. Make visual

check of burner and pilot flame. Yellow flame indicates

clogging of air openings. Lifting or blowing flame indi-

cates high gas pressure. Low flame indicates low gas

pressure.

TYPICAL MAIN BURNER FLAME

Fig. # 8144

NOTE: Modulating burner flame varies in height from

approximately 1/4" at low fire to approximately 4" at

high fire.

CONTROLS

Check all controls to see that they are operational.

To check electronic safety (IID Models), turn off main

burner. Observe pilot burner when shutting off pilot

gas. Ignition spark should go on. Main gas valve will

also drop out.

To check high limit switch, turn dial setting down to

a point slightly below the temperature of the water

leaving the heater. The reset button should snap out

and the burner should shut-off. Reset dial to 30°F to

40°F above desired operating temperature, and push

reset button. Burner should light.

SUGGESTED INSPECTION SCHEDULE

The boiler should be inspected on the first and third

months after initial start-up and then on an annual

basis. If problems are found, refer to Troubleshooting

Guide for additional directions.

1. Remove top of heater and inspect heat exchanger

for soot and examine venting system.

2. Remove rear header and inspect for scale depos-

its, and/or accelerated erosion.

*3. Inspect pilot and main burner flame and firing rate.

*4. Inspect and operate all controls and gas valve.

*5. Visually inspect system for water leaks.

*6. a. Oil pump motor and bearing assembly, if oil

cups are provided.

b. Disconnect pump from header and check

condition of pump impeller. Check condition

of bearing by attempting to move impeller

from side to side. Replace any parts showing

wear.

c. Check pump coupler for wear and vibration.

7. Check flow switch paddle.

8. Clean room air intake openings to ensure ad-

equate flow of combustion and ventilation air.

CAUTION: Combustion air must not be contaminated

by corrosive chemical fumes which can damage the

boiler and void the warranty.

9. Keep boiler area clear and free from combustible

materials, gasoline, and other flammable vapors

and liquids.

*Should be checked monthly. (Takes approximately

15 minutes).

29

PILOT BURNER FLAME

(STANDING PILOT UNITS)

Fig #9336

Fig #8964.1