Raypak RAYTHERM 0133-4001 User Manual

Page 17

RECOMMENDED PURGE MANIFOLDS FOR

TYPICAL HYDRONIC SYSTEM HOOKUPS

The boiler piping system of a hot water heating

boiler connected to heating coils located in air handling

units where they may be exposed to refrigerated air

circulating, must be equipped with flow control valves

or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle.

TEMPERATURE & PRESSURE GAUGE

The temperature & pressure gauge is standard

equipment on all hydronic heating and hot water supply

boilers. All temperature & pressure gauges are factory

mounted in the in/out header except for residential

boilers, Models 133 and 181-401. On these models the

temperature & pressure gauge is shipped loose for

field installation, and located in the outlet water

connection. All fittings required to mount gauge to

piping system are supplied by others.

17

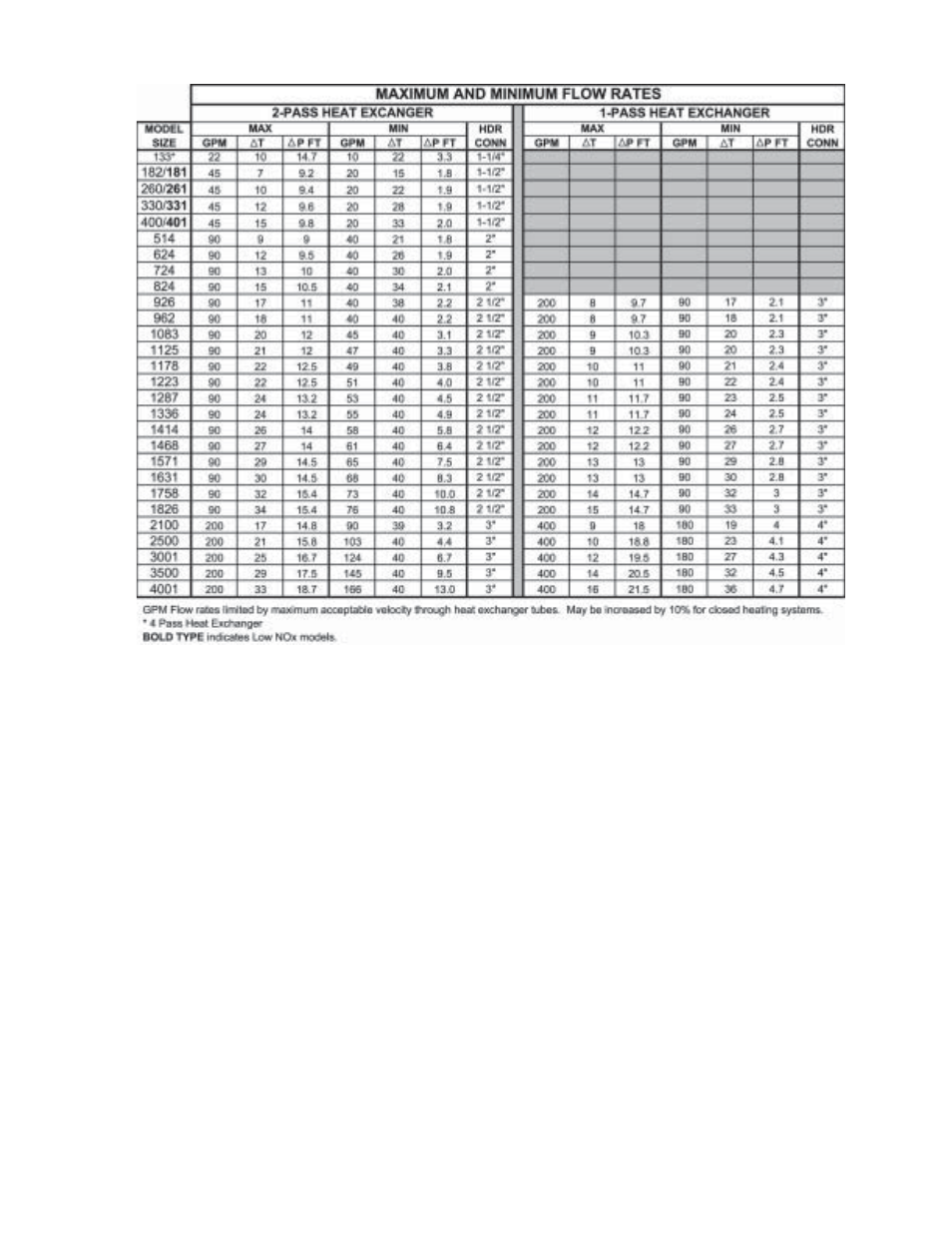

PUMP SELECTION

In order to ensure proper hydraulics in your

hydronic heating system, adequate pump size must be

selected. We recommend that the pump be sized for

20°F Delta T. (Delta T is the temperature difference

between the inlet and outlet water when the boiler is

firing at full rate). For some boilers, the Delta T is more

than 20°F (22°-33°F) at the recommended flow rates.

FEEDWATER REGULATOR

We recommend that a feedwater regulator be

installed and set at 12 PSIG minimum pressure. Install

a check valve or back flow device upstream of the

regulator, with a manual shut-off valve. Leave the

valve open.

PIPING - HEATING BOILERS

We recommend that all high points be vented and

that purge valves and a bypass valve be installed. A

boiler installed above radiation level must be provided

with a low water cut-off device. The boiler, when used

in conjunction with a refrigeration system, must be

installed so that the chilled medium is piped in parallel

with the boiler with appropriate valves to prevent the

chilled medium from entering the boiler.