Operating controls, Electronic ignition, Controls economaster controls – Raypak RAYTHERM 0133-4001 User Manual

Page 21

OPERATING CONTROLS

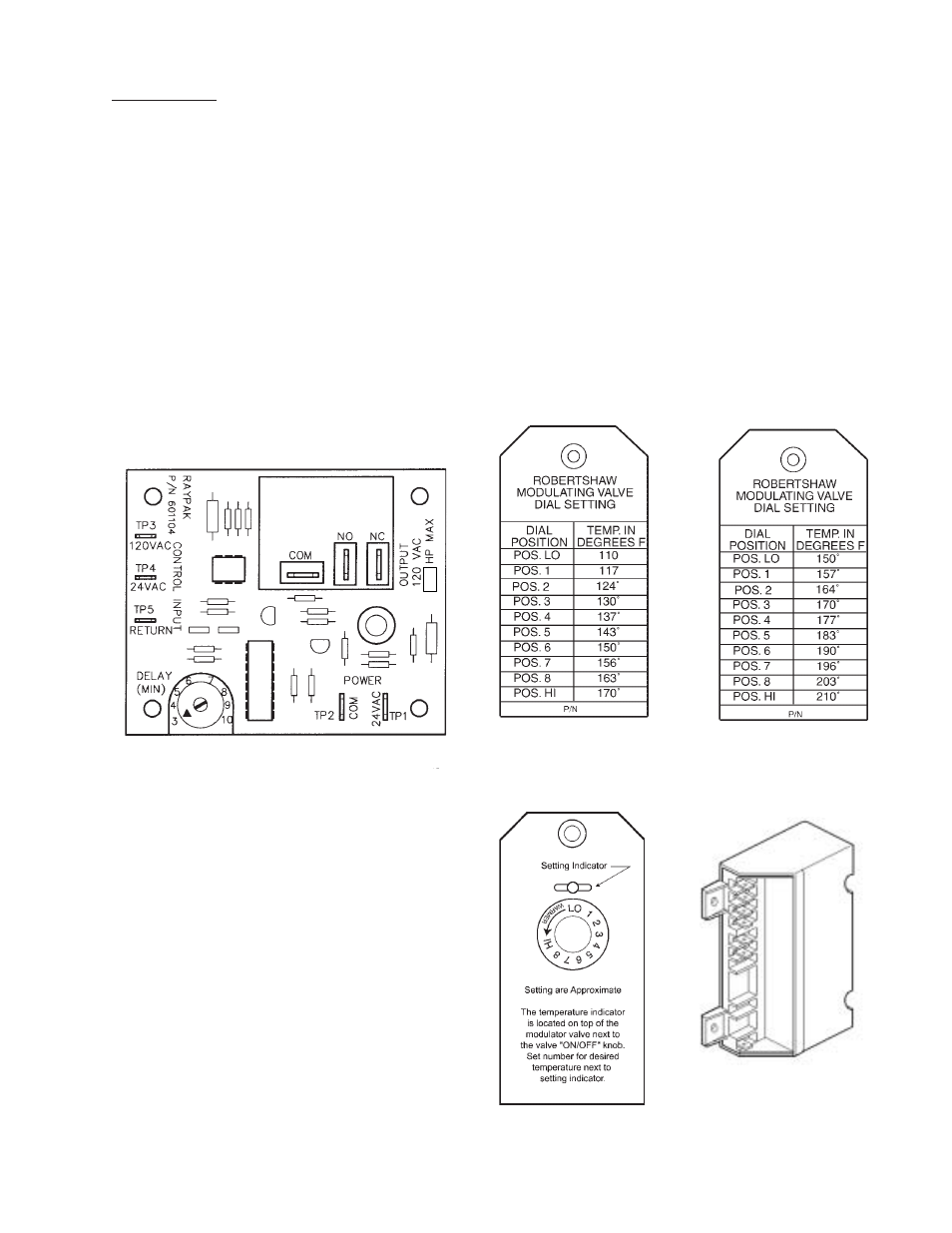

Models 133-1826 with mechanical modulating

controls have one or more Robertshaw Unitrol 7000

Series hydraulic snap-on thermostatic combination

gas valves. These valves have the pressure regulator

and 24 volt operator built-in. The hydraulic actuator

will throttle the boiler input to adjust the firing rate and

meet the required load. This, in effect, prevents costly

fuel consumption, as compared to an on-off cycling

boiler. The valve has a remote capillary bulb im-

mersed in a well, at the header outlet, to maintain a

constant outlet water temperature. When multiple

valves are furnished, they can be staged to give

greater flexibility of control. Standard factory setting is

at position 5. Consult the dial setting tag attached to

the control for your desired temperature. See sample

tag drawings below.

LOW TEMP. RANGE

HIGH TEMP. RANGE

IGNITION MODULE

ELECTRONIC SAFETY

ACAD: ECONO. DWG.

Fig. #8645.1

Fig. #8645

Fig. # 8929.1

21

3/4

ELECTRONIC IGNITION

The intermittent ignition device conserves energy

by automatically extinguishing the pilot when desired

temperature is reached. When additional heat is

needed, the pilot re-ignites electrically, eliminating the

fuel costs of maintaining a constant pilot. To ensure

safe operation, the gas valve cannot open until the pilot

relights and is proven.

All units are shipped with lockout ignition module

as standard.

CONTROLS

ECONOMASTER CONTROLS

The Raytemp Economaster II is an electronic de-

vice that allows the operator to set the desired time for

the pump to run after the boiler shuts off. The time is

factory-set at 7 minutes and it can be re-adjusted in the

field anywhere from 3 to 10 minutes.

In a conventional system, when the aquastat is

satisfied, the main gas valve closes, but the pump

continues operating. With the new energy-conserving

Economaster II the boiler pump is programmed to

continue running for an optimum period of time in order

to absorb the residual heat from the combustion cham-

ber and use it in the system. The pump then shuts off

until the next call for heat is received from the aquastat.

NOTE: Pump will come on when power is first applied

to boiler.