Raypak RAYTHERM 0133-4001 User Manual

Page 14

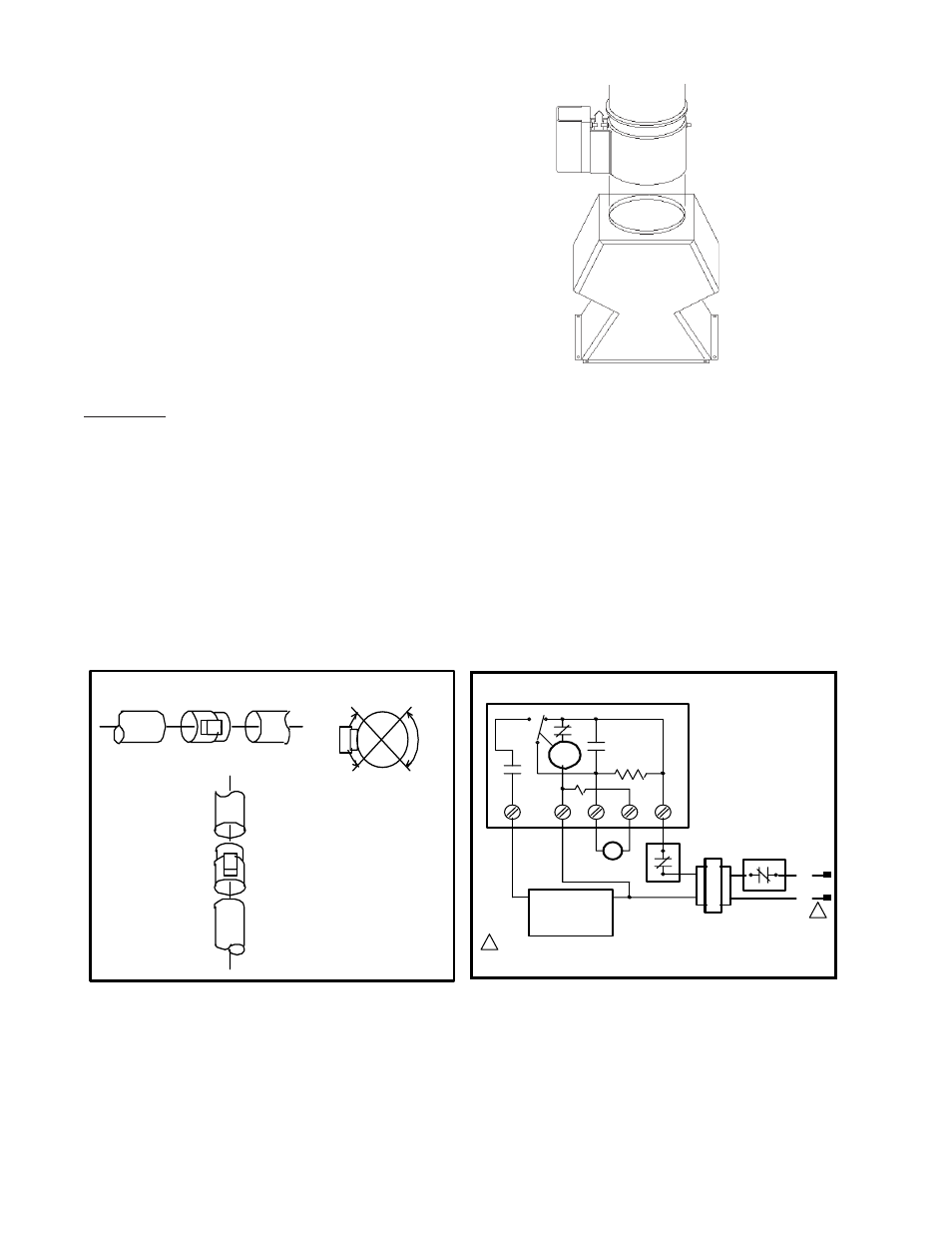

VENT DAMPER INSTALLATION

(MODELS 133 THROUGH 261)

WHERE REQUIRED

LOCATION

The vent damper must be located in the vent so

that it serves only the appliance for which it is intended.

If improperly installed, a hazardous condition, such

as an explosion or carbon monoxide poisoning, could

result. Make certain that it is mounted in an accessible

location at least 6 inches from any combustible mate-

rial or the heat exchanger, and that the position indica-

tor is in a visible location.

The vent damper must be installed after the appli-

ance drafthood, as close to the drafthood as practi-

cable, and without modification of the drafthood.

Fig. # 8182.0

VENT DAMPER INSTALLATION

VENT DAMPER GENERAL WIRING DIAGRAM

Fig. # 8183.0

Fig. # 8615.0

WARNING: Do not use thermally actuated vent dampers on a modulating boiler. To do so, may result in

asphyxiation. Use only a mechanically actuated vent damper device that is electrically interlocked with the

modulating boiler operation.

On vertical vents, the vent damper may be mounted with the actuator in any position. On horizontal vents,

do not mount the actuator either directly above or directly below the vent pipe; mount the vent damper actuator

to the side of the vent.

The vent damper is set up for a continuous pilot system. If the vent damper is installed on an Intermittent

Pilot or Direct Spark Ignition equipped system, the energy savings of the vent damper can be improved by

plugging the hole in the vent damper blade using the knockout plug, Part No. 105612R, provided in the parts

envelope.

DO NOT plug the hole if installing the vent damper on a continuous pilot system as this will create a hazard.

NO

YES

NO

YES

INSTALL VENT

DAMPER WITH

ACTUATOR TO

SIDES OF VENT

ONLY. DO NOT

MOUNT ABOVE OR

BELOW VENT.

TO CHIMNEY

TO BOILER

D808

FLOW >

HORIZONTAL INSTALLATION

TO CHIMNEY

TO BOILER

D808

VERTICAL

INSTALLATION

ACTUATOR MAY BE

INSTALLED IN ANY

POSITION ON

VERTICAL PIPE.

Motor

End

Switch

C.

N.O.

N.C.

1K2

1K1

R

1R

1K3

1

2

3

4

5

D808

Thermostat or

Controller

Dual Valve

Combination Gas

Control or

Ignition System

Optional Limit

Location

Limit

Transformer

L1

(Hot)

L2

1

1

Yellow Blue

Power supply provide disconnect me

ans an overload protection as requ

ired.

Black Orange Red

14

Note: Model 133 drafthood shown.

Power supply provide disconnect means an overload protection as required.