Maintenance – Porter-Cable CPFC2TV3525VP User Manual

Page 13

13 - ENG

N015840

Risk of unsafe operation. Compressed air from the unit may

contain wa ter condensation and oil mist. Do not spray un fil tered air at an item

that could be damaged by moisture. Some air tools and accessories may

require filtered air. Read the in struc tions for the air tools and accessories.

How to Start

1. Turn the Auto/Off lever to "Auto" and allow tank pressure to build. Motor will

stop when tank pressure reaches "cut-out" pressure.

2. Pull the regulator knob out and turn clockwise to increase pressure. When the

desired pressure is reached push knob in to lock in place.

Risk of unsafe operation. If any unusual noise or vibration is

noticed, stop the compressor immediately and have it checked by a trained service

technician.

The compressor is ready for use.

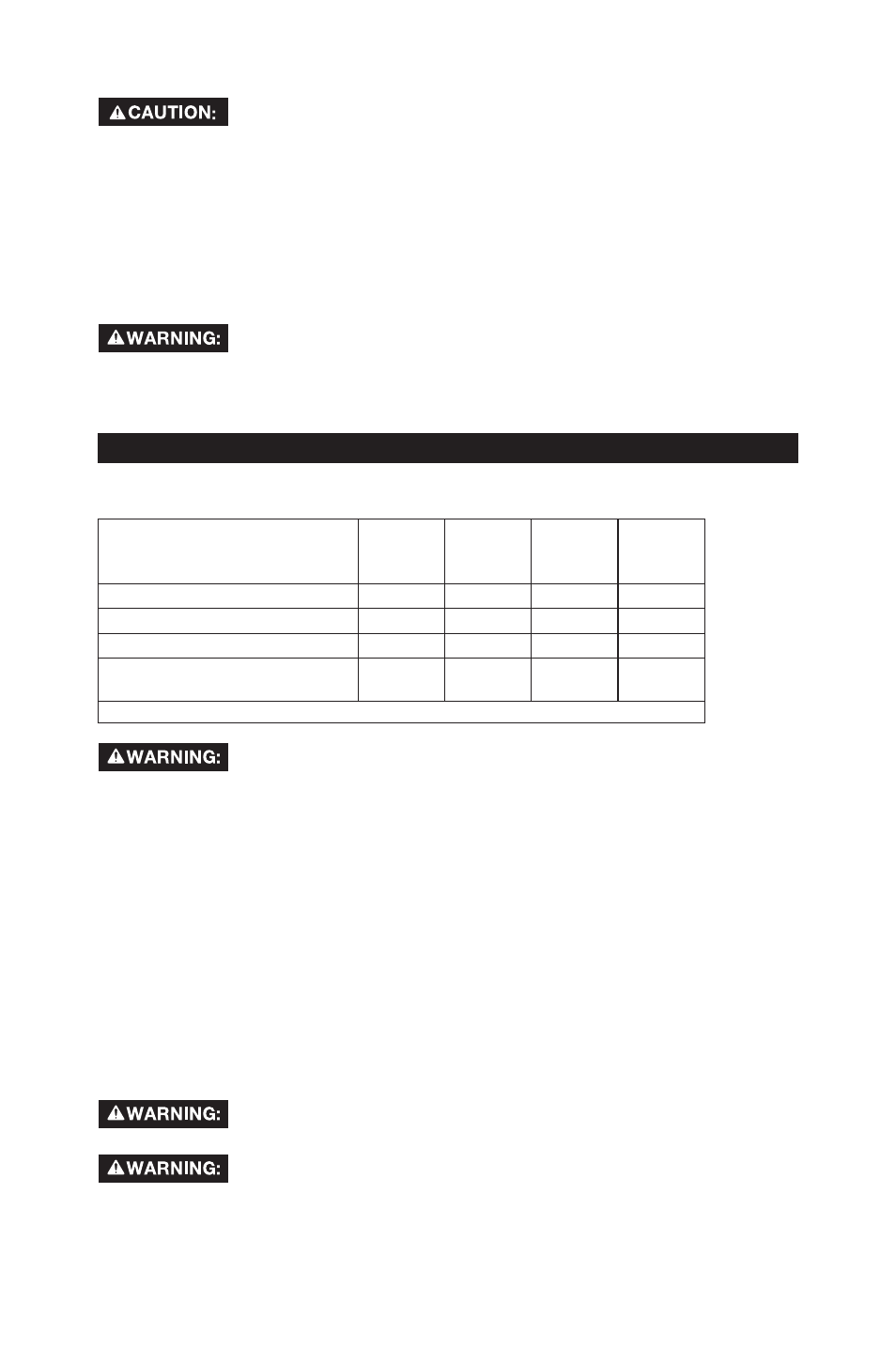

MAINTENANCE

CUSTOMER RESPONSIBILITIES

Before

each

use

Daily

or after

each use

Every 100

hours

Yearly

Check Safety Valve

X

Drain Tank

X

Air Filter

X

1

Air compressor pump intake

and exhaust valves

X

1- more frequent in dusty or humid conditions

Risk of Unsafe Operation. Unit cycles automatically when

power is on. When servicing, you may be exposed to voltage sources, com-

pressed air, or moving parts. Before servicing unit unplug or disconnect elec-

trical supply to the air compressor, bleed tank of pressure, and allow the air

compressor to cool.

To ensure efficient operation and longer life of the air compressor, a routine mainte-

nance schedule should be prepared and followed. The above routine maintenance

schedule is geared to an air compressor in a normal working environment operating

on a daily basis. If necessary, the schedule should be modified to suit the condi-

tions under which your air compressor is used. The modifications will depend upon

the hours of operation and the working environment. Compressors in an extremely

dirty and/or hostile environment will require a greater frequency of all maintenance

checks.

NOTE: See Operation section for the location of controls.

TO CHECk SAFETY VALVE

Risk of Bursting. If the safety valve does not work properly,

over-pressurization may occur, causing air tank rupture or an explosion.

Risk from Flying Objects. Always wear certified safety equip-

ment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields.