Porter-Cable CPFC2TV3525VP User Manual

Page 11

11 - ENG

N015840

DESCRIPTION OF OPERATION

Become familiar with these controls before operating the unit.

Auto(I)/Off(O) Switch: Place this switch in the "Auto (I)" position to provide auto-

matic power to the pressure switch and "Off (O)" to remove power at the end of

each use.

Pressure Switch: The pressure switch automatically starts the motor when the

air tank pressure drops below the factory set "cut-in" pressure. It stops the motor

when the air tank pressure reaches the factory set "cut-out" pressure.

Safety Valve: If the pressure switch does not shut off the air compressor at its

"cut-out" pressure setting, the safety valve will protect against high pressure by

"popping out" at its factory set pressure (slightly higher than the pressure switch

"cut-out" setting).

Outlet Pressure Gauge: The outlet pressure gauge indicates the air pressure

available at the outlet side of the regulator. This pressure is controlled by the regula-

tor and is always less than or equal to the tank pressure.

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure

in the tank.

Regulator: Controls the air pressure shown on the outlet pressure gauge. Pull

the knob out and turn clockwise to increase pressure and counterclockwise to

decrease pressure. When the desired pressure is reached push knob in to lock in

place.

Universal Quick-Connect Body: The universal quick-connect body accepts the

three most popular styles of quick-connect plugs- Industrial, automotive (Tru-flate),

and ARO. One hand push-to-connect operation makes connections simple and

easy.

Drain Valve: The drain valve is located at the base of

Drain

Valve

the air tank and is used to drain condensation at the

end of each use.

Cooling System (not shown): This compressor

contains an advanced design cooling system. At the

heart of this cooling system is an engineered fan. It is

perfectly normal for this fan to blow air through the vent holes in large amounts. You

know that the cooling system is working when air is being expelled.

Air Compressor Pump (not shown): Compresses air into the air tank. Working

air is not available until the compressor has raised the air tank pressure above that

required at the air outlet.

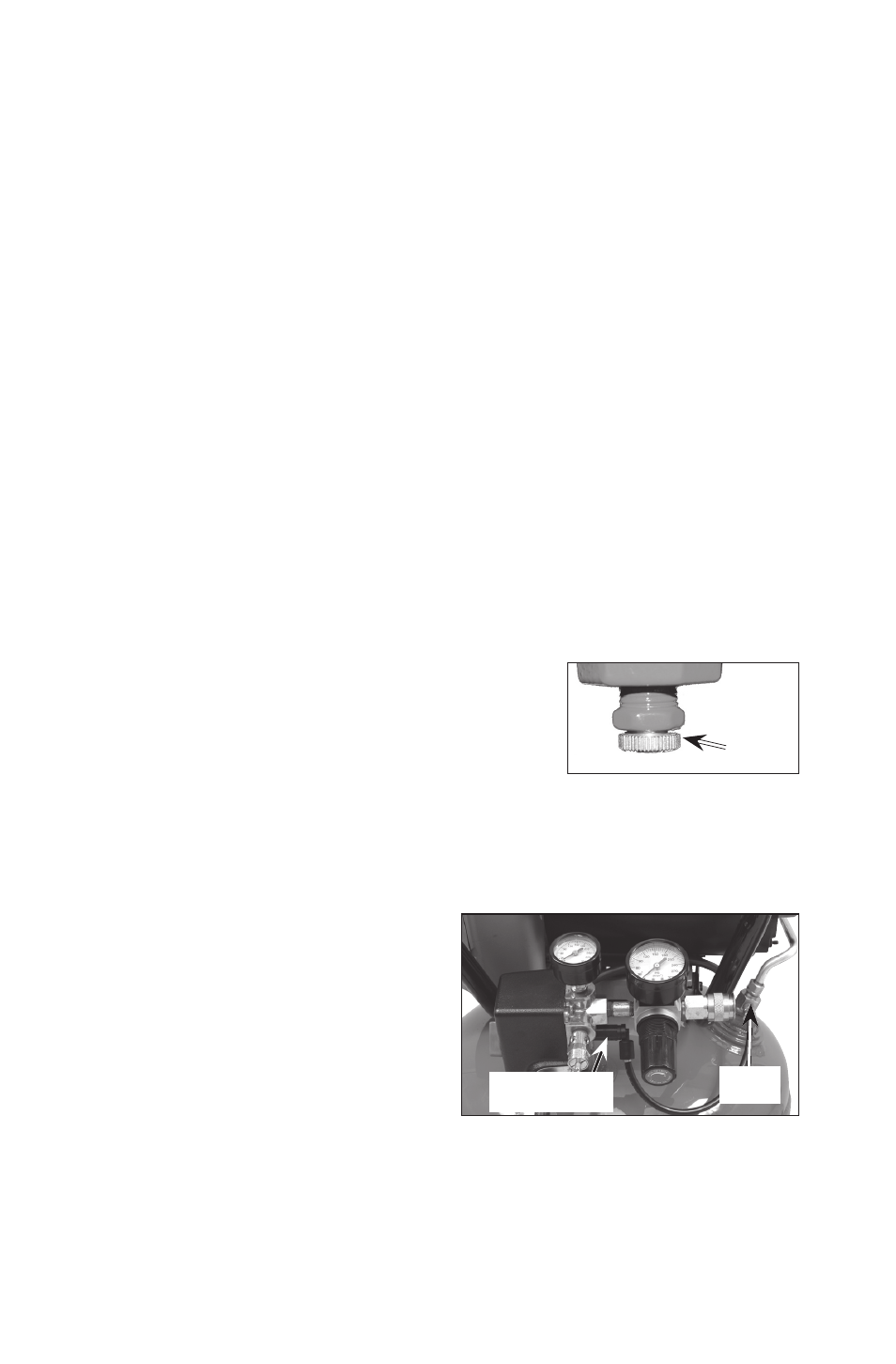

Check Valve: When the air compressor is

Pressure

Release Valve

Check

Valve

operating, the check valve is "open",

allowing compressed air to enter the air

tank. When the air compressor reaches

"cut-out" pressure, the check valve "clos-

es", allowing air pressure to remain inside

the air tank.

Pressure Release Valve: The pressure

release valve located on the side of the

pressure switch, is designed to automati-

cally release compressed air from the compressor head and the outlet tube when

the air compressor reaches "cut-out" pressure or is shut off. The pressure release

valve allows the motor to restart freely. When the motor stops running, air will be

heard escaping from this valve for a few seconds. No air should be heard leak-

ing when the motor is running, or continuous leaking after unit reaches "cut-out"

pressure.