P.d. (1), P.d. (2) – Pioneer PRO-610HD User Manual

Page 28

220

PRO-610HD, PRO-510HD, SD-582HD5, SD-532HD5

1. P.D. (1)

Failure in the POWER SUPPLY Assy and the AUDIO Assy.

There are four main possibilities:

1. Abnormality in the regulator of the heater

2. Blown fuse(s) in secondary

3. Abnormality in RELAY (RY102)

4. Abnormality in AUDIO OUTPUT

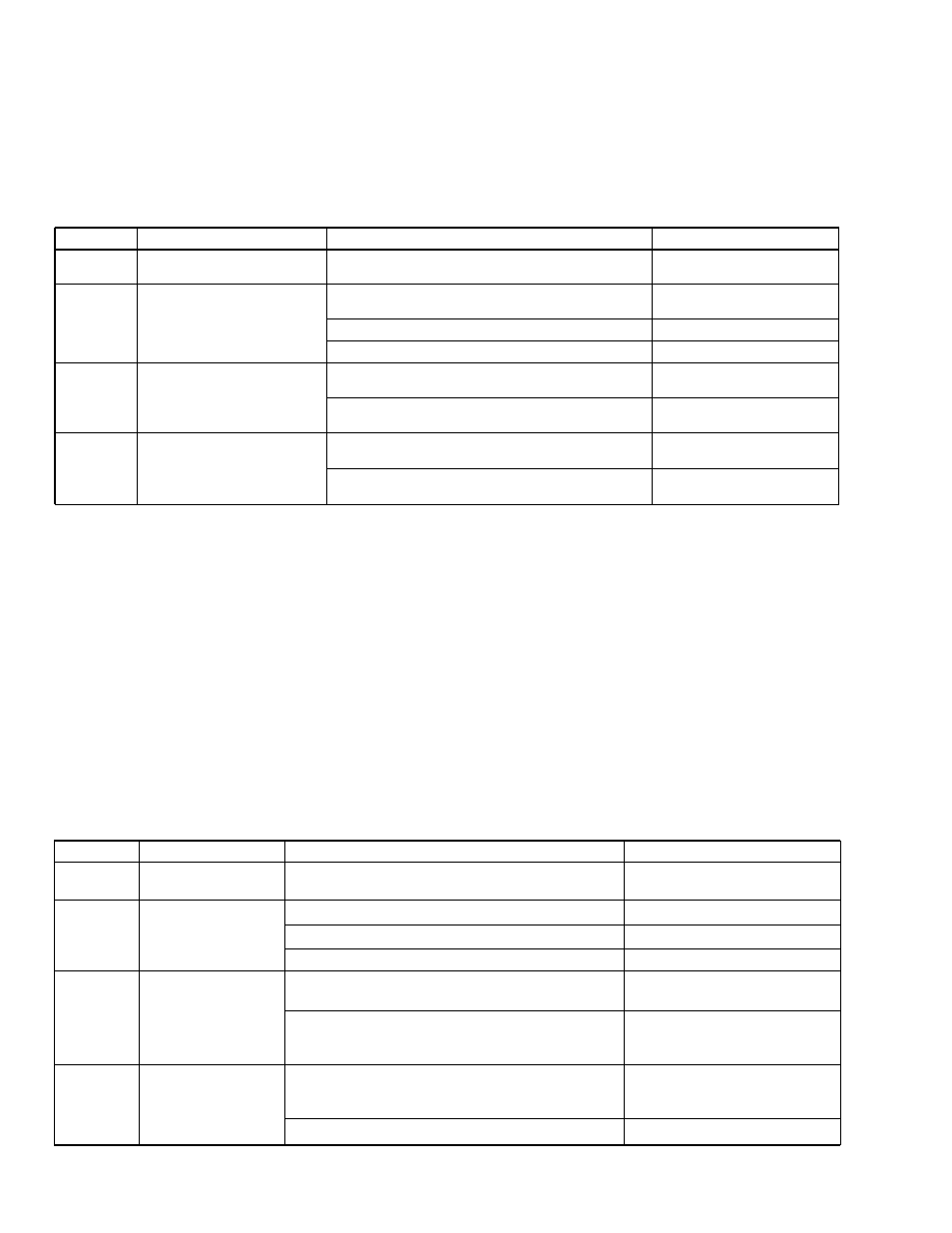

Status

Causes

Check Items

Probable Defective Parts

D223

ANODE Hi

Abnormality in the regulator for

the heater

The voltage of HT- at TP205 is NOT approx. 19 V, and

that of the HT+ at TP204 is NOT approx. 26 V.

Q201, R202, D210, D209

D207

ANODE Hi

Blown fuse(s)

The voltage HT+ (approx. 26 V) at TP204 is NOT

supplied.

CONV. AMP Assy and

DEFLECTION SERVICE Assy

The voltage (approx. 35 V) at TP203 is NOT supplied.

AUDIO Assy

The voltage (approx. 11 V) at TP209 is NOT supplied.

VIDEO Assy

D911

ANODE Hi

Abnormality in RELAY

The RELAY signal is NOT high (ON) at TP904.

SIGNAL Assy

P.D. even if the RELAY signal is high (ON) at TP904.

Q904, Q905 RY102, R102

D203

ANODE Hi

Abnormality in AUDIO OUTPUT

The SP line (CN5611) is disconnected.

Connect the SP line.

The voltage at the negative electrode of the C5616 and

C5617 is 5.2 V or more.

C5616, C5617 (VIDEO Assy)

Note: The anode of the diode is high only for a short time after the power is turned on until the protection circuits are activated (P.D.) The

LEDs are lit by the HOLD circuit.

In a case when the power cannot be on with no LED lit, check the following:

1. Check if the FU101 fuse in the POWER SUPPLY Assy is blown.

2. Disconnect and check connector E1 (CN201) to see whether STB 5 V is supplied.

If STB 5 V is supplied, replace the SIGNAL Assy. If STB 5 V is NOT supplied, replace the POWER SUPPLY Assy.

3. Disconnect and check connector E1 (CN201) to see whether AC CLK is supplied.

If AC CLK is supplied, replace the SIGNAL Assy. If AC CLK is NOT supplied, replace the POWER SUPPLY Assy.

2. P.D. (2)

Failure in the DEFLECTION SERVICE Assy.

There are four main possibilities:

1. H. deflection overload detection (1)

2. H. deflection stopping detection

3. H. deflection overload detection (2)

4. X-ray protection

Status

Causes

Check Items

Probable Defective Parts

D312

ANODE Hi

Overload detection 1

Q309, Q324 (short-circuited between

C and E)

D309

ANODE Hi

Stopping H. deflection

Is the connector of the deflection yoke plugged in?

Plug in the connector.

No H. OSC signal at TP304 (F=31.5 kHz, Duty 50%)

IC301, Q309

No DH. BLK signal at TP305

Q309

D615

ANODE Hi

Overload detection 2

Q612, Q613 (short-circuited between

C and E)

About one minute after the power is turned off, disconnect

the K4 connector and turn on the power. Then the power is

not turned off (no P.D.).

IC5101, IC5151 and IC5201 in the

CRT DRIVE Assy

D621

ANODE Hi

X-ray protection

No change in the ABL voltage (no DC change) at Pin 12 of

the CN305 when a 100%-white signal is repeatedly

connected and disconnected

D2224 (short-circuited)of the SUB

VIDEO Assy

T601 (FBT) rare short