Gas connections, Connecting gas supply piping – Lochinvar 800 User Manual

Page 41

Installation & Operation Manual

41

7

Gas connections

Connecting gas supply piping

1.

Remove the top access panel and refer to FIG.’s 7-1 thru

7-3 to pipe gas to the boiler.

a.

Install ground joint union for servicing, when

required.

b.

Install a manual shutoff valve in the gas supply

piping outside boiler jacket when required by local

codes or utility requirements.

c.

In Canada – When using manual main shutoff

valves, it must be identified by the installer.

2.

Install sediment trap / drip leg.

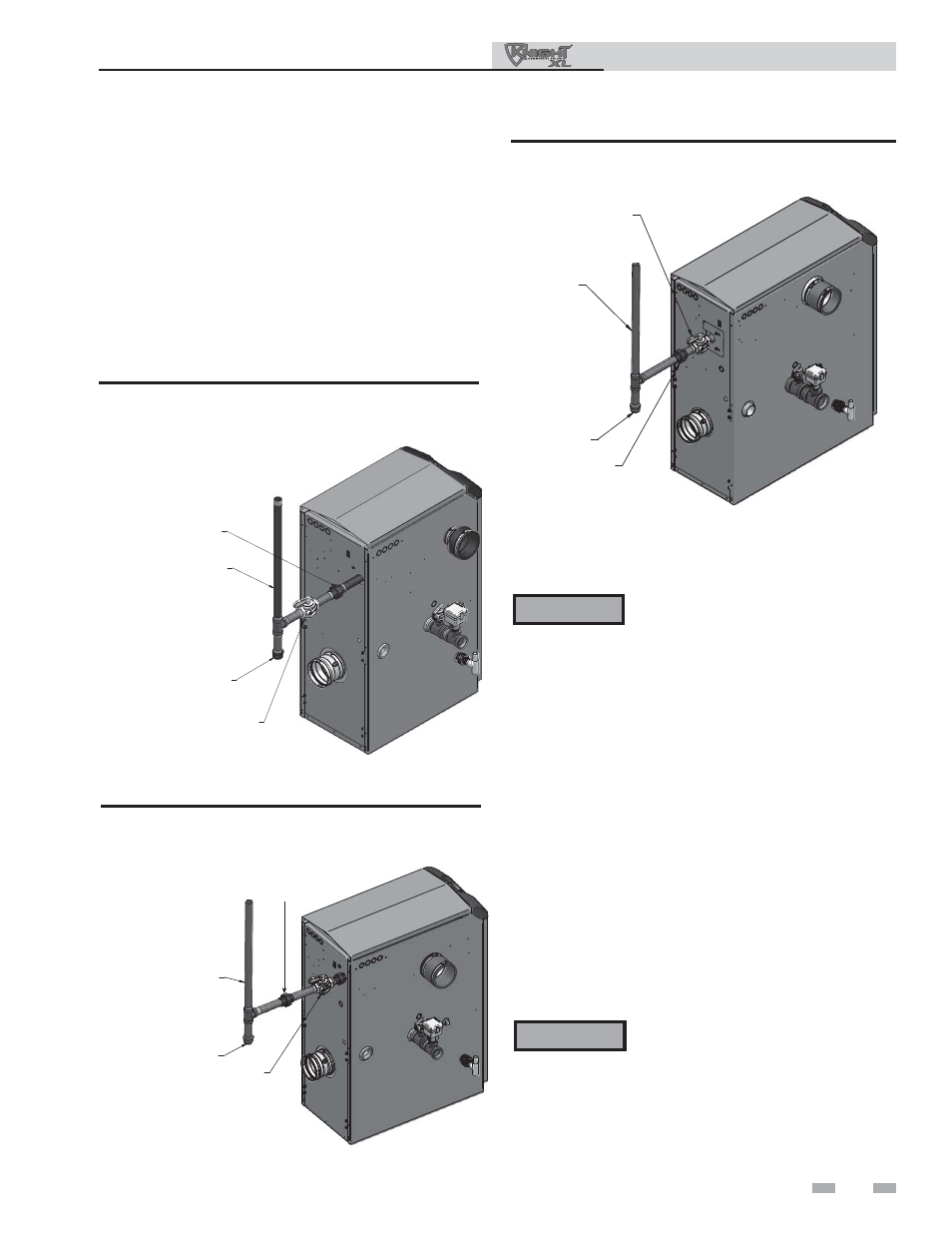

Figure 7-1 Gas Supply Piping - Model 399

3.

Support piping with hangers, not by the boiler or its

accessories.

Do not check for gas leaks with an open

flame – use the bubble test. Failure to use

the bubble test or check for gas leaks can

cause severe personal injury, death, or

substantial property damage.

MANUAL

SHUTOFF VALVE

(FACTORY SUPPLIED)

GAS SUPPLY

UNION

FIELD SUPPLIED

SEDIMENT TRAP / DRIP LEG

Figure 7-3 Gas Supply Piping - Models 600 - 800

4.

Purge all air from the gas supply piping.

5.

Before placing the boiler in operation, check the boiler

and its gas connection for leaks.

a.

The appliance must be disconnected from the gas

supply piping system during any pressure testing of

that system at a test pressure in excess of 1/2 PSIG

(3.5 kPa).

b.

The appliance must be isolated from the gas supply

piping system by closing a manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSIG

(3.5 kPa).

c.

The appliance and its gas connection must be leak

tested before placing it in operation.

The gas valve and blower will not support

the weight of the piping. Do not attempt

to support the weight of the piping with

the boiler or its accessories. Failure to

comply could result in severe personal

injury, death, or substantial property

damage.

ƽ WARNING

ƽ WARNING

6.

Use pipe sealing compound compatible with propane

gases. Apply sparingly only to male threads of the pipe

joints so that pipe dope does not block gas flow.

UNION

GAS SUPPLY

MANUAL

SHUTOFF VALVE

(FIELD SUPPLIED)

SEDIMENT TRAP / DRIP LEG

Figure 7-2 Gas Supply Piping - Model 500

GAS SUPPLY

DRIP LEG

MANUAL

SHUTOFF VALVE

(FACTORY SUPPLIED)

UNION