Hydronic piping, Near boiler piping connections, Installation & operation manual – Lochinvar 800 User Manual

Page 36: Flow switch adjustment, Circulator sizing

Installation & Operation Manual

36

6

Hydronic piping

Near boiler piping connections

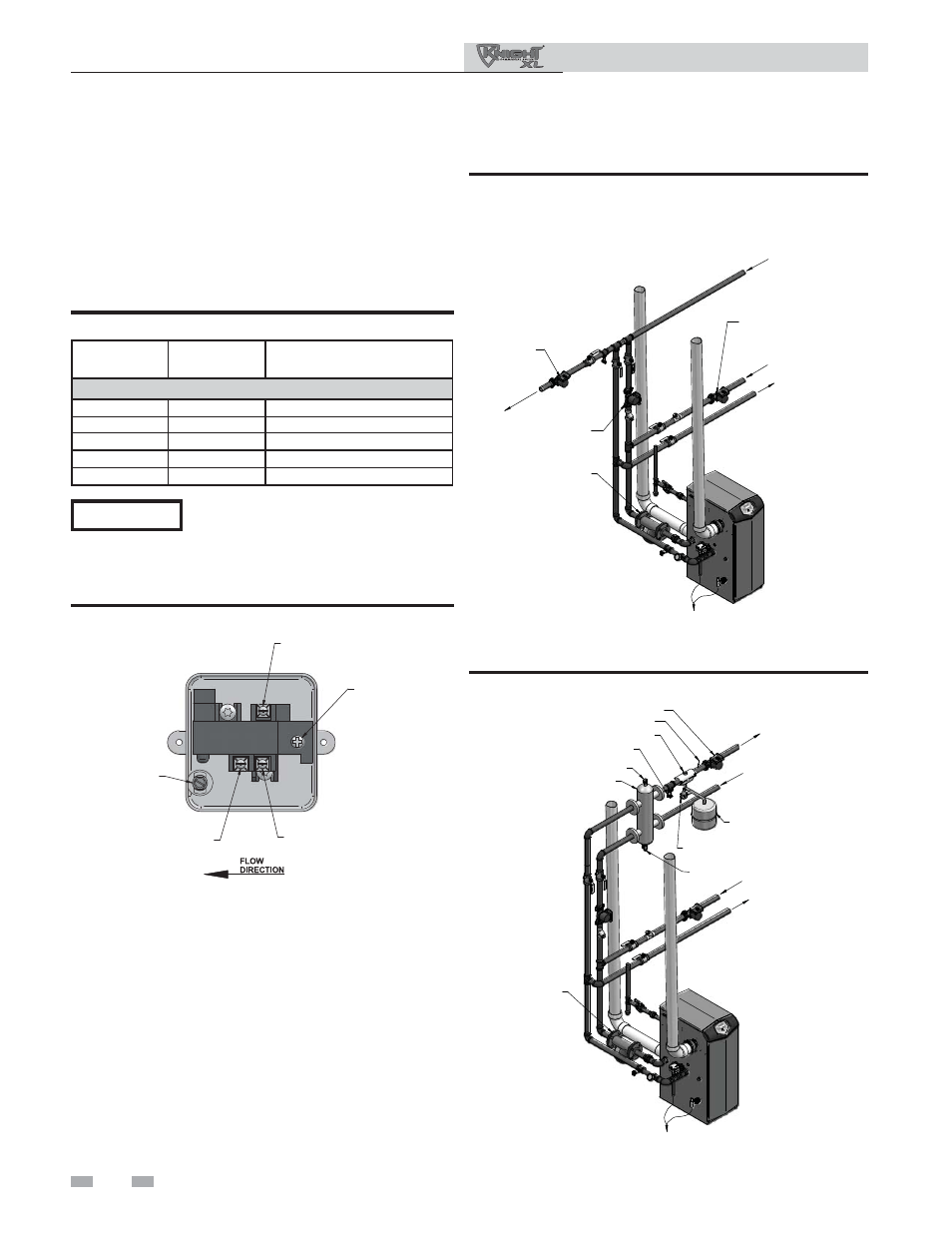

Y-STRAINER

(RECOMMENDED)

BOILER PUMP

INDIRECT

DOMESTIC

HOT WATER

TANK

SYSTEM PUMP

TO FLOOR

DRAIN

TO

FROM

FROM SYSTEM

TO SYSTEM

DOMESTIC HOT

WATER PUMP

Figure 6-4A Near Boiler Piping w/Y-Strainer

Figure 6-3 Flow Switch Adjustment

Flow switch adjustment

Refer to Table 6A for the proper setting of the sensitivity

screw. For reference, the position of the screw prior to setting

should be turned clockwise with a Phillips driver until it stops

(FIG. 6-3). Proceed to turn the screw counterclockwise the

amount of turns listed in Table 6A based on the model.

Consult the manufacturer’s instructions for wiring the flow

switch to your system.

NORMALLY

OPEN

SENSITIVITY

ADJUSTMENT

NORMALLY

CLOSED

COMMON

GROUND

NOTICE

Turn the sensitivity screw clockwise to

increase the flow rate required to activate

the switch. Turn the sensitivity screw

counterclockwise to decrease the flow rate

required to activate the switch.

MODEL

PADDLE SIZE

SENSITIVITY SCREW

ADJUSTMENT

Note: Paddles are included with the flow switch.

399

#3

7½ turns

500

#3

5½ turns

600

#3

7¼ turns

700

#3

5¼ turns

800

#3

3¼ turns

Table 6A Paddle Size / Sensitivity Screw Adjustment

Circulator sizing

The Knight XL heat exchanger does have a pressure drop,

which must be considered in your system design. Refer to the

graphs in FIG’s 6-5 and 6-6 for pressure drop through the

Knight XL heat exchanger.

DRAIN

(TYPICAL)

AIR SEPARATOR

AIR VENT VALVE

EXPANSION TANK

LOW LOSS HEADER

(TYPICAL)

Y-STRAINER

(RECOMMENDED)

DRAIN VALVE

FAST FILL VALVE

INDIRECT

DOMESTIC

HOT WATER

TANK

SYSTEM SENSOR

SYSTEM PUMP

TO FLOOR

DRAIN

TO

FROM

FROM SYSTEM

TO SYSTEM

Figure 6-4B Near Boiler Piping w/Low Loss Header