Commercial pool heaters, Operation, Continued – Lochinvar GAS HEATER FOR COMMERICAL POOL APPLICATIONS User Manual

Page 46

Commercial Pool Heaters

46

OPERATION

Continued

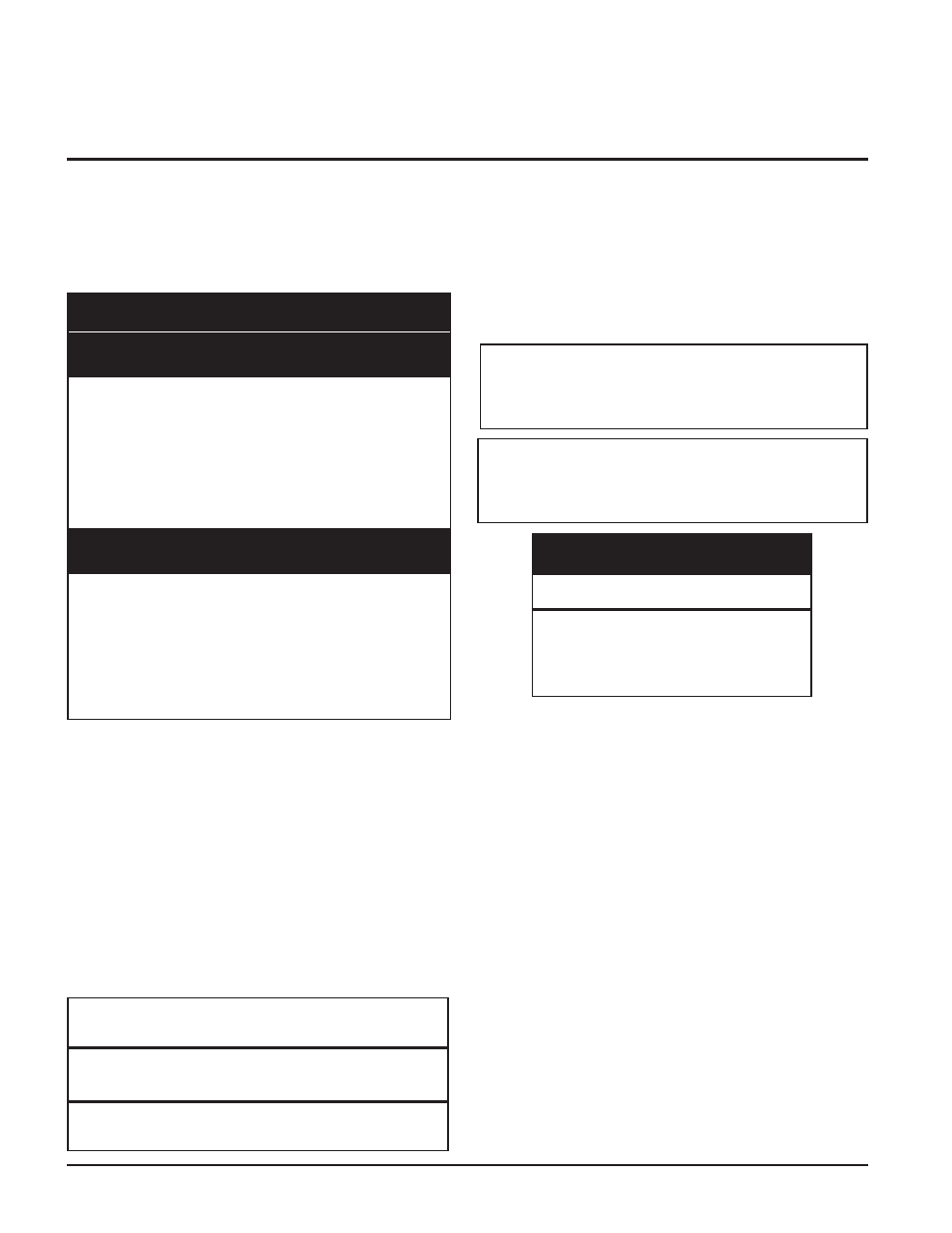

Pipe Size Requirements

The pipe sizing chart provides the minimum pipe size for

common manifold piping to ensure adequate flow.

Circulating Pump

1. This pool heater is factory supplied with a properly sized

pump that circulates water between the pool heater and

system.

2. The pump is sized to pool heater input and water hardness.

See Water Chemistry on page 44.

3. Lubricate the pump to the manufacturer’s

recommendations. Pump damage due to inadequate

lubrication is non-warrantable. Use SAE 30 non-detergent

oil or lubricant specified by the pump manufacturer.

4. Standard pool heaters are furnished with the following

circulating pump mounted in the factory supplied pool

loop.

This pump is sized based on installation of a single pool heater

in close proximity with the system. If the number of fittings

and straight pipe exceeds the quantities shown in this section,

a larger pump will be required. As an alternative to changing

the pump in these circumstances, the piping can be changed to

a sub-loop. Check pump for correct pump rotation.

The standard pump selection is based on the following pipe

and fittings from the pool heater to the system:

Minimum Pump Performance

Pump performance is based on providing adequate flow and

temperature rise to prevent scale accumulation in the heat

exchanger. See Water Chemistry on page 44.

Heat Exchanger

This is a highly sophisticated heat exchanger, designed to carry

water in such a way that it generates a scouring action which

keeps all interior surfaces free from build-up of impurities. The

straight-line, two pass design of the tubes sends water into the

headers at a properly rated velocity. The configuration of the

headers, in turn, creates a high degree of turbulence which is

sufficient to keep all contaminants in suspension. This

“scouring action” provides greater cost savings for owners.

Tubes are always able to transfer heat at peak efficiency. Every

surface within this water containing section is of a non-ferrous

material, providing clear, clean, rust-free water. Straight

copper tubes-finned on the outside for maximum heat transfer-

coated cast iron one piece cored headers make up an entirely

rust-proof pool heater. A Cupro-Nickel heat exchanger is

standard on 1,800,000 - 2,070,000 Btu/hr models. On all

models, header inspection plugs can be removed for field

inspection and cleaning of copper tubes. The entire heat

exchanger may be easily removed from the pool heater.

500,000 - 750,000 Btu/hr Models

1/4 HP, 120 VAC, 5.8 Amp

990,000 - 1,440,000 Btu/hr Models

1/2 HP, 120 VAC, 7.4 Amp

1,800,000 - 2,070,000 Btu/hr Models

3/4 HP, 120 VAC, 8.8 Amp

6 - 90° elbows 2 - ball valves

2 - unions

1 - cold water tee

Not more than 45 feet of straight pipe.

IMPORTANT: For every elbow and tee in excess

of those shown above, deduct 5 feet from the

maximum allowable straight pipe in the pool

heater to the system circulating loop.

Btu/hr Input

GPM

Ft.Hd.

500,000 - 750,000

55

10

990,000 - 1,440,000

90

15

1,800,000 - 2,070,000

115

18

TABLE-S

Minimum Pump Performance

1

2"

2

3"

3

3 1/2"

4

4"

5

5"

6

5"

1

2 1/2"

2

4"

3

4"

4

5"

5

6"

6

6"

TABLE-R

Pipe Sizing Chart

Number of Units

Common Pipe

500,000 - 750,000 Btu/hr Models Size (Min.)

Number of Units

Common Pipe

990,000 - 2,070,000 Btu/hr Models Size (Min.)