Commercial pool heaters, Iin ns st ta al ll la at tiio on n, Continued – Lochinvar GAS HEATER FOR COMMERICAL POOL APPLICATIONS User Manual

Page 30: Gas manifold pressure adjustment

IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N

Continued

Gas Manifold Pressure Adjustment

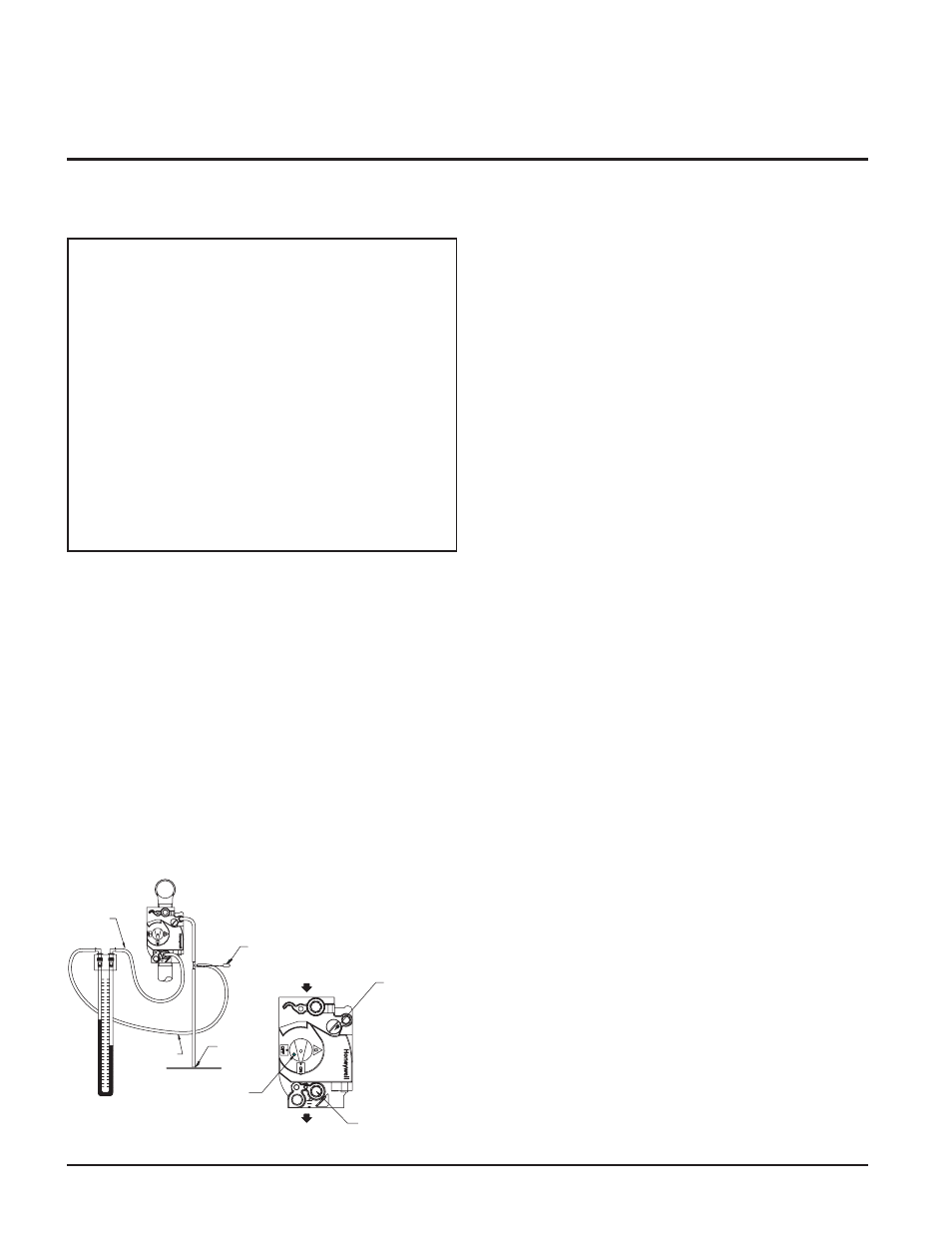

IMPORTANT: The gas valves are referenced to

the fan pressurized chamber by a hose

connected from the vent of the gas valve

regulator to the chamber pressure tap located on

the front inside portion of the jacket. Reference

the drawings in this section for component and

connection points for pressure measurement.

The procedure for connecting a manometer or

magnahelic must be followed to obtain actual net

manifold pressure for normal operation. A

manometer or magnahelic gauge legible in 0.1"

increments up to 10 inches w.c. is required to

check and adjust the manifold pressure. The

regulator cover screw on the gas valve must be

in place and tight at all times for the pool heater

to operate properly.

1. Remove the thumbscrew that fastens the control panel

access door and pull out the control panel.

2. Turn the power switch located in the lower left corner

behind the control panel access door to the “O” or “OFF”

position.

3. Remove the top front jacket access panels to access the gas

valves.

4. Locate the reference hose on the second gas valve which

goes from the vent fitting on the gas valve to a barbed

fitting on the deck of the pool heater (see Figure 31).

5. Remove the flexible cap from the barbed fitting on the

“tee” located in this line and hook one side of the

manometer, or (-) side of a magnahelic gauge, to this “tee”.

Retain this cap for future use.

Figure 31 – Measuring Net Manifold Gas Pressure

6. Remove the 1/8" hex plug from the manifold pressure tap

on the gas valve (see Figure 31). Retain plug for future

use.

7. Install a fitting in this tap that is suitable for connection of

a hose to a manometer, or (+) side of a magnahelic gauge

(see Figure 31).

8. Turn the power switch to the “I” or “ON” position.

9. Push the reset button(s) for the ignition control(s), if

necessary.

10. Set the temperature control to call for heat (see

Programming Temperature Control, page 41).

11. Once the pool heater is firing the manometer/magnahelic

will reflect the Manifold Gas Pressure. Compare this

reading to the respective value in TABLE-L, page 31 for

Natural Gas or Propane Gas.

12. If adjustment is necessary, remove the regulator cover

screw on the gas valve.

Note: If the gas valve under adjustment is located on a

manifold assembly monitored by an igniter, the pool heater

may shut down and recycle when the regulator cover screw is

removed. This is normal.

13. Turn the regulator adjustment screw “clockwise”

to

raise the regulator gas pressure. Turn the regulator

adjustment screw “counterclockwise”

to lower the

regulator gas pressure.

14. Replace the regulator cover screw and make sure it is tight

for proper operation.

15. Read the value on the manometer/magnahelic and compare

it to the values in TABLE-L.

16. Repeat this adjustment procedure for each gas valve as

necessary to adjust to the proper manifold gas pressure.

17. Remove hoses, replace and tighten plugs and caps when

complete.

18. Replace top front upper jacket access panels and control

panel door in reverse order.

19. If proper ignition and burner operation is not achieved after

checking gas supply pressure, see Cleaning and

Maintenance, page 49 for Combustion Air Fan

Adjustment. Follow the procedure to adjust the

combustion air fans as necessary.

Commercial Pool Heaters

30

INLET

OUTLET

MANOMETER

4

4

3

3

2

2

1

1

0

0

1

1

2

2

3

3

4

4

CAP

MANIFOLD

PRESSURE

CHAMBER

PRESSURE

BARBED

FITTING

GAS

VALVE

CONTROL

KNOB

PRESSURE

REGULATOR

ADJUSTMENT

(UNDER CAP SCREW)

1/8" HEX

MANIFOLD

PRESSURE

TAP