Commercial pool heaters, Iin ns st ta al ll la at tiio on n, Continued – Lochinvar GAS HEATER FOR COMMERICAL POOL APPLICATIONS User Manual

Page 24

IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N

Continued

2. On horizontal runs, do not install vent pipe with seams

pointing down. Position vent pipe so that the seams are on

the top side of the vent pipe.

3. Secure all joints with a minimum of three sheet metal

screws or pop rivets. Apply aluminum foil duct tape or

silicone sealant to all screws or rivets installed in the vent

pipe.

4. Ensure that the air inlet pipes are properly supported.

ƽ

WARNING: Properly seal all joints and

seams in the inlet vent piping system. Failure to

do so may result in flue gas recirculation,

spillage of flue products, and carbon monoxide

emissions. Carbon monoxide poisoning can

cause severe personal injury or death.

Combined Combustion Air Inlet Points

You can combine the air inlet pipes from multiple pool heaters

to a single common connection if the common air inlet pipe

has a cross sectional area equal to or larger than the total area

of all air inlet pipes connected to the common air inlet pipe.

Example: Two 8" (20.3cm) air inlet pipes (50.3 in

2

[324.5cm

2

]

area each) have a total area of 100.6 in

2

(645.2cm

2

), requiring

a 12" (30.5cm) (113.1 in

2

[729.7cm

2

]) common air inlet pipe.

The air inlet point for multiple pool heater air inlets must be

provided with an exterior opening which has a free area equal

to or greater than the total area of all air inlet pipes connected

to the common air inlet. This exterior opening for combustion

air must connect directly to the outdoors. The total length of

the combined air inlet pipe must not exceed a maximum of 50

(15.2m) equivalent feet. You must deduct the restriction in area

provided by any screens, grills, or louvers installed in the

common air inlet openings and some rooftop terminations.

Screens, grills, or louvers installed in the common air inlet can

reduce the free area of the opening from 25% to 75% based on

the materials used.

Vertical and Sidewall Combustion Air Inlet

IMPORTANT: To prevent recirculation of flue

products into the combustion air inlet, follow all

instructions in this section.

ƽ

WARNING:

Locate and install the

combustion air inlet termination correctly.

Failure to do so can allow the discharge of flue

products to be drawn into the combustion

process. This can result in incomplete

combustion and potentially hazardous levels of

carbon monoxide in the flue products. This will

cause operational problems and the spillage of

flue products. Spillage of flue products can

cause personal injury or death due to carbon

monoxide poisoning.

You must locate the combustion air cap and the flue gas outlet

on the same rooftop surface (vertical direct vent system) or

sidewall surface (horizontal direct vent system) and in the

same pressure zone as the vent termination. Follow all

clearance requirements listed on pages 8 and 9.

Purchase and assemble the combustion air inlet cap to protect

the air inlet from wind and weather.

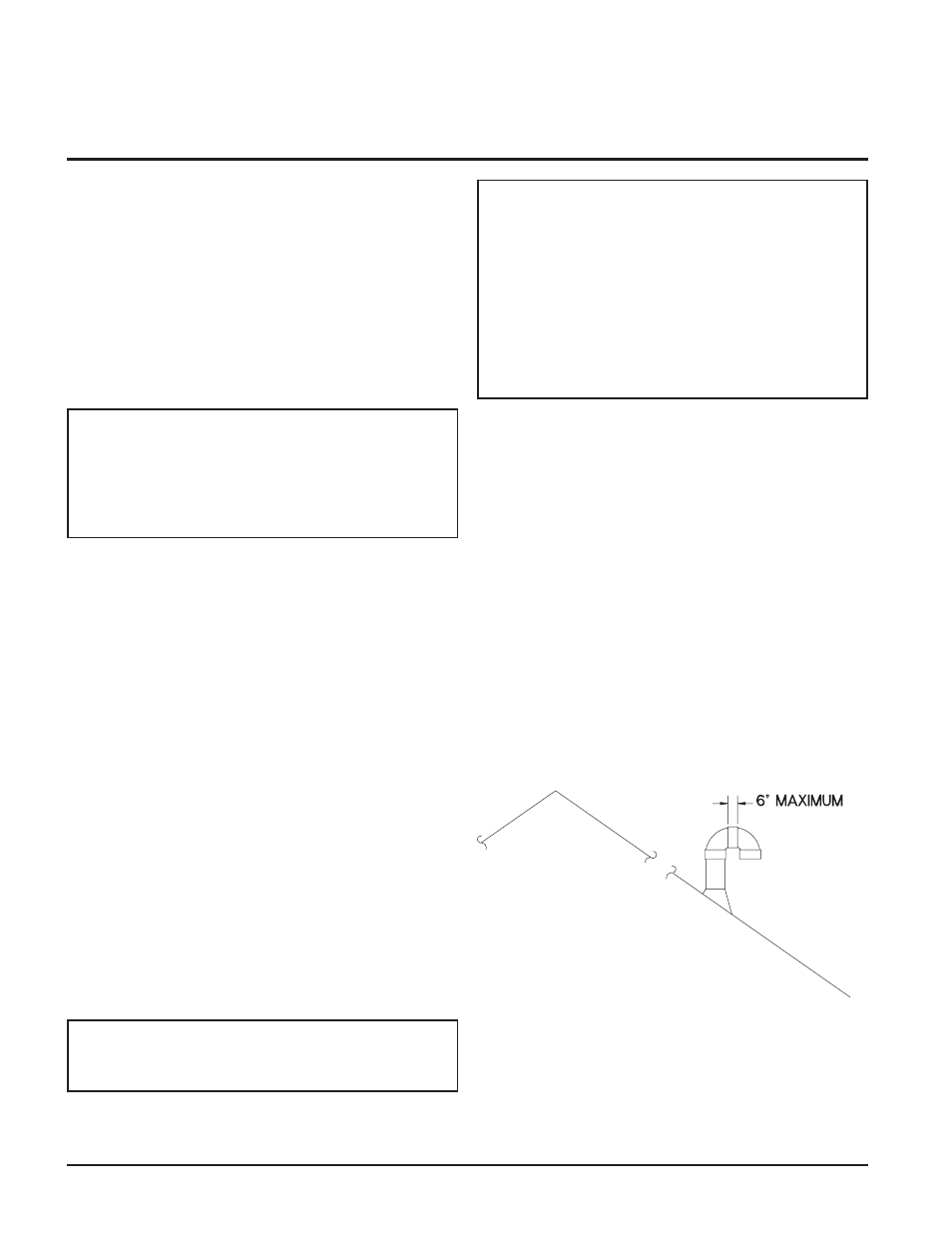

Alternatively, assemble the combustion air inlet cap for the

vertical rooftop air inlet from items purchased locally. The air

inlet cap consists of two 90° elbows installed to the air inlet

pipe (see Figure 26). Install the first 90° elbow on the rooftop

at the highest vertical point of the air inlet pipe. Install the

second 90° elbow on the horizontal outlet of the first elbow.

The outlet of the second 90° elbow will be pointing down. You

may use a 90° elbow and a 90° street elbow to make this

assembly. If you use a straight piece of pipe between the two

90° elbows, it should not exceed 6" (51mm) in length.

Figure 26 – Vertical Rooftop Air Inlet

For horizontal direct vent termination of combustion air, you

must use the termination cap from the pool heater

manufacturer. The sidewall air inlet cap is available as part of

a direct vent kit. See TABLE–G for Horizontal Direct Vent

Kits.

Commercial Pool Heaters

24