Commercial pool heaters, Iin ns st ta al ll la at tiio on n, Continued – Lochinvar GAS HEATER FOR COMMERICAL POOL APPLICATIONS User Manual

Page 22

IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N

Continued

90° elbow. Subtract 2.5 feet (0.7m) of equivalent length for each

45° elbow.

Masonry Chimney Installation

Do not use a standard masonry chimney to directly vent the

combustion products from this pool heater.

To use a masonry chimney, the chimney must use a sealed,

corrosion-resistant liner system. Sealed, corrosion-resistant liner

systems (singlewall, doublewall, flexible, or rigid) must be rated

for use with a high efficiency, positive pressure vent system.

Corrosion-resistant chimney liner systems are typically made

from a high grade stainless steel such as AL29-4C. The liner

must be properly sized and fully sealed throughout the entire

length. Both the top and bottom of the masonry chimney must

be capped and sealed to provide a dead air space around the liner.

ƽ

WARNING: Do not vent this pool heater into a

masonry chimney without a sealed stainless steel

liner system. Any breaks, leaks, or damage to the

masonry flue/tile will allow the positive-pressure

flue products to leak from the chimney and into

occupied living spaces. This could cause serious

injury or death due to carbon monoxide poisoning

and other harmful flue products.

IMPORTANT: Check with local code officials to

determine code requirements or the advisability of

using a masonry chimney with a sealed corrosion-

resistant liner system.

Vertical DV Venting Termination

You must use the vent termination recommended by the vent

manufacturer for vertical direct vent terminations. Follow all

vertical venting termination information for clearances and

location under Vertical Vent Termination Clearances and

Location, page 10.

Horizontal DV Venting Termination

Horizontal venting (air inlet and flue outlet on the same wall)

uses the pool heater’s internal combustion air blowers to force

the flue products out of the horizontally-terminated flue.

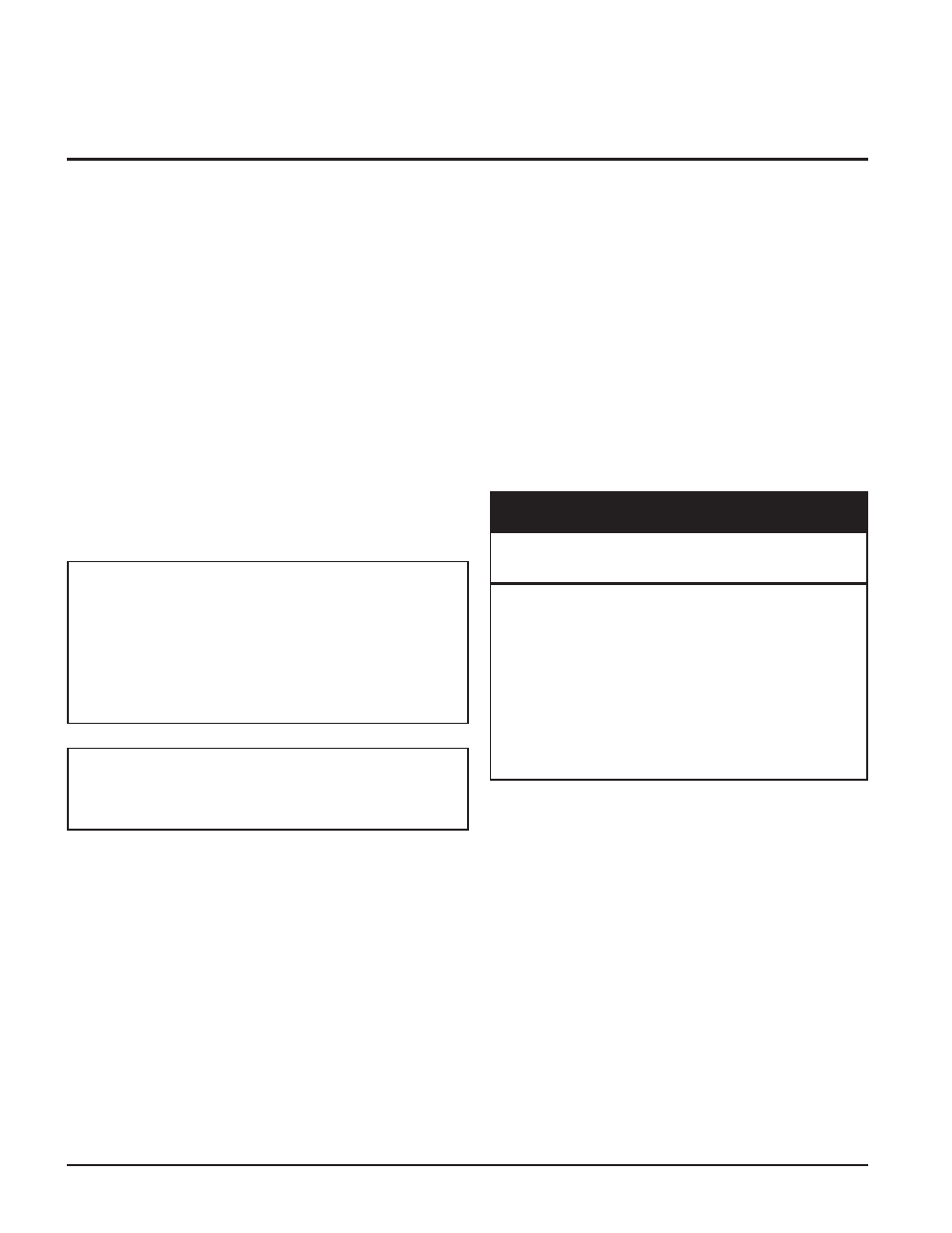

You must purchase a horizontal direct vent kit from the pool heater

manufacturer to ensure proper operation. See TABLE–G, this

page, to determine which horizontal direct vent kit you need.

When installing the vent cap, the wall opening must provide an air

space clearance of 2 inches (5.1cm) around the flue pipe. The

diameter of the opening for installation of the sidewall cap will be

4 inches (10.2cm) larger (minimum) than the nominal diameter of

the installed vent pipe to the horizontal vent cap.

Install the horizontal vent cap from the outside. Mount the vent

cap to the wall using four screws or wall anchors. Seal under the

screw heads with caulking. Install the sealed, AL29-4C vent

pipe from the pool heater to the vent cap.

Horizontal Vent Termination Clearances and Location

Follow all sidewall venting termination information for

clearances and location under Sidewall Vent Termination

Clearances and Location, page 11.

* The DVK kit includes a DV box adapter, air inlet cap, and a sidewall vent termination. The

VDK kit includes a DV box adapter and an air inlet cap. See note on page 12 concerning

DV box adapter.

Flue Pipe Materials

The following manufacturers supply flue materials suitable for

these models. All materials are made with AL29-4C stainless

steel. Call the numbers below for the nearest distributor.

Heat-Fab, Inc. Saf-T CI Vent. 1-800-772-0739.

Protech Systems, Inc. Fas-N-Seal Vent. 1-800-766-3473.

Metal-Fab, Inc. Corr/Guard Vent. 1-800-835-2830.

Combustion Air Inlet Piping

The Direct Vent system requires the installation of a pipe to

supply combustion air from the outdoors directly to the pool

heater. The air inlet piping can either be brought in horizontally

from a sidewall or vertically from the rooftop. Make sure the

combustion air inlet is in the same pressure zone as the vent

terminal.

Commercial Pool Heaters

22

Input Horizontal

Vertical

Btu/hr

Kit*

Kit*

500,000

DVK3004

VDK3026

650,000

DVK3005

VDK3027

750,000

DVK3005

VDK3027

990,000

DVK3000

VDK3023

1,260,000

DVK3001

VDK3024

1,440,000

DVK3001

VDK3024

1,800,000

DVK3002

VDK3024

2,070,000

DVK3002

VDK3024

TABLE-G

Direct Vent Kits