Installation and service manual – Lochinvar GAS HEATER FOR COMMERICAL POOL APPLICATIONS User Manual

Page 35

Installation and Service Manual

35

Relief Valve

This pool heater is supplied with a relief valve(s) sized in

accordance with ASME Boiler and Pressure Vessel Code,

Section IV. The relief valve(s) is installed in the vertical

position and mounted in the hot water outlet. Place no other

valve between the relief valve and the pool heater. To prevent

water damage, pipe the discharge from the relief valve to a

suitable floor drain for disposal when relief occurs. Do not

install any reducing couplings or other restrictions in the

discharge line. The discharge line will allow complete drainage

of the valve and line. Manually operate the relief valves at least

once a year.

Automatic Chlorinator and

Chemical Feeders

All chemicals must be diluted into the pool water being

circulated through the pool heater. Any concentration of

chlorine in the pool heater can cause damage to the pool heater.

Do not place chlorine tablets or bromine sticks in the skimmer.

High chemical concentrations will result when the pump is not

running.

Chlorinator must feed downstream of the pool heater and

have an anti-siphoning device to prevent chemical back-up in

the pool heater when the pump is shut off.

Water Flow Switch

A water flow switch is standard equipment. The wiring

connection installs the flow switch in the 24 VAC safety circuit

to prove water flow before main burner ignition. The standard

flow switch is installed in the outlet side of the piping loop

when shipped from the factory. These pool heaters require a

sufficient flow of 26 GPM to make the flow switch and start

burner operation.

IMPORTANT: High chemical concentrations from

improperly adjusted feeders and Chlorinator can

cause rapid corrosion to the heat exchanger. This

damage is non-warrantable.

ƽ

CAUTION: Avoid contact with hot discharge

water.

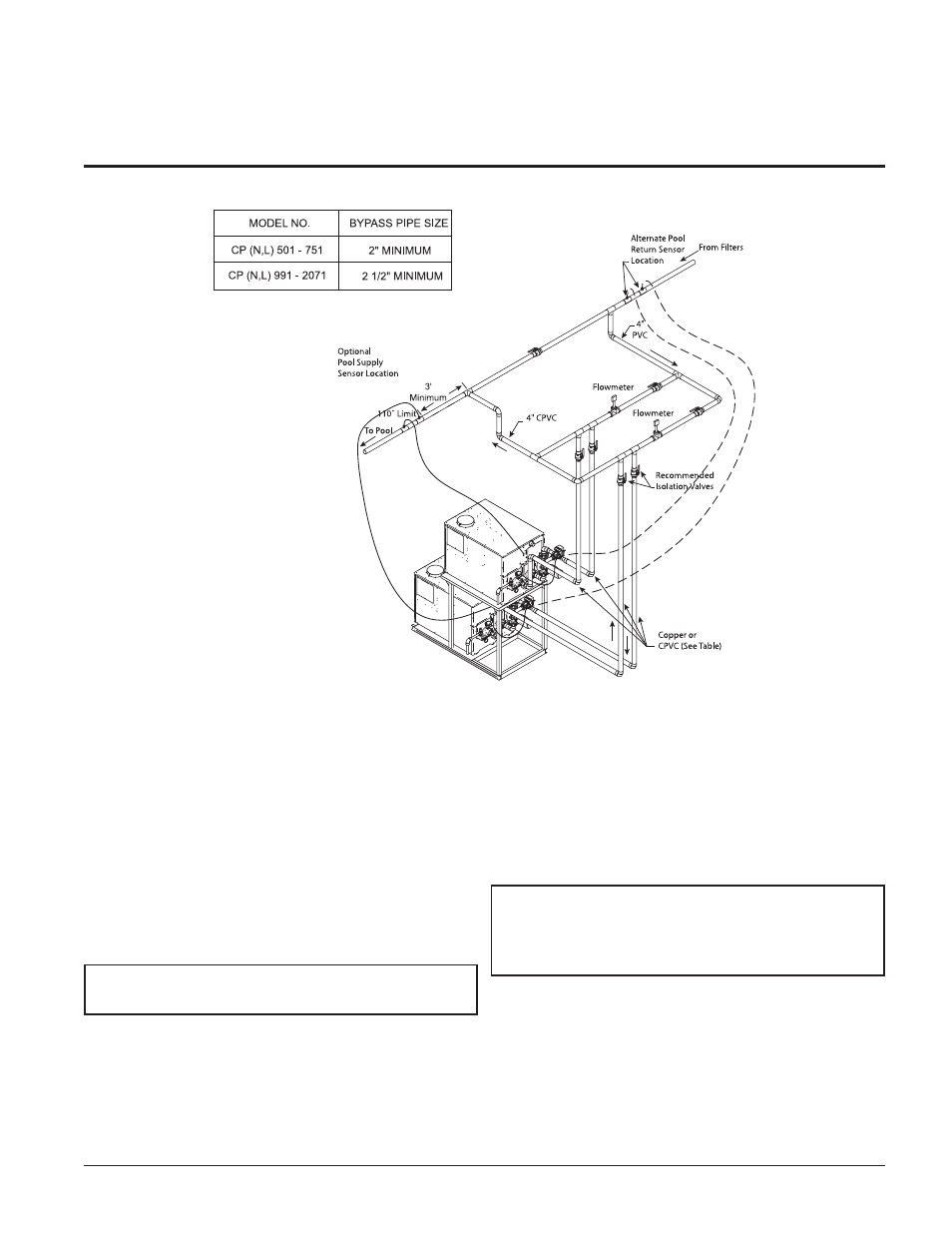

Figure 38 - Multi-Stack Frame - Heaters are Beyond 15 feet from Pool Piping