Installation, Installation with a chilled water system – Lochinvar 000 - 2 User Manual

Page 26

INSTALLATION

Continued

Sludge formed as the result of excessive oxygen in the system

can restrict water flow resulting in a premature boiler failure.

Any boiler damage due to excessive oxygenation is non-

warrantable.

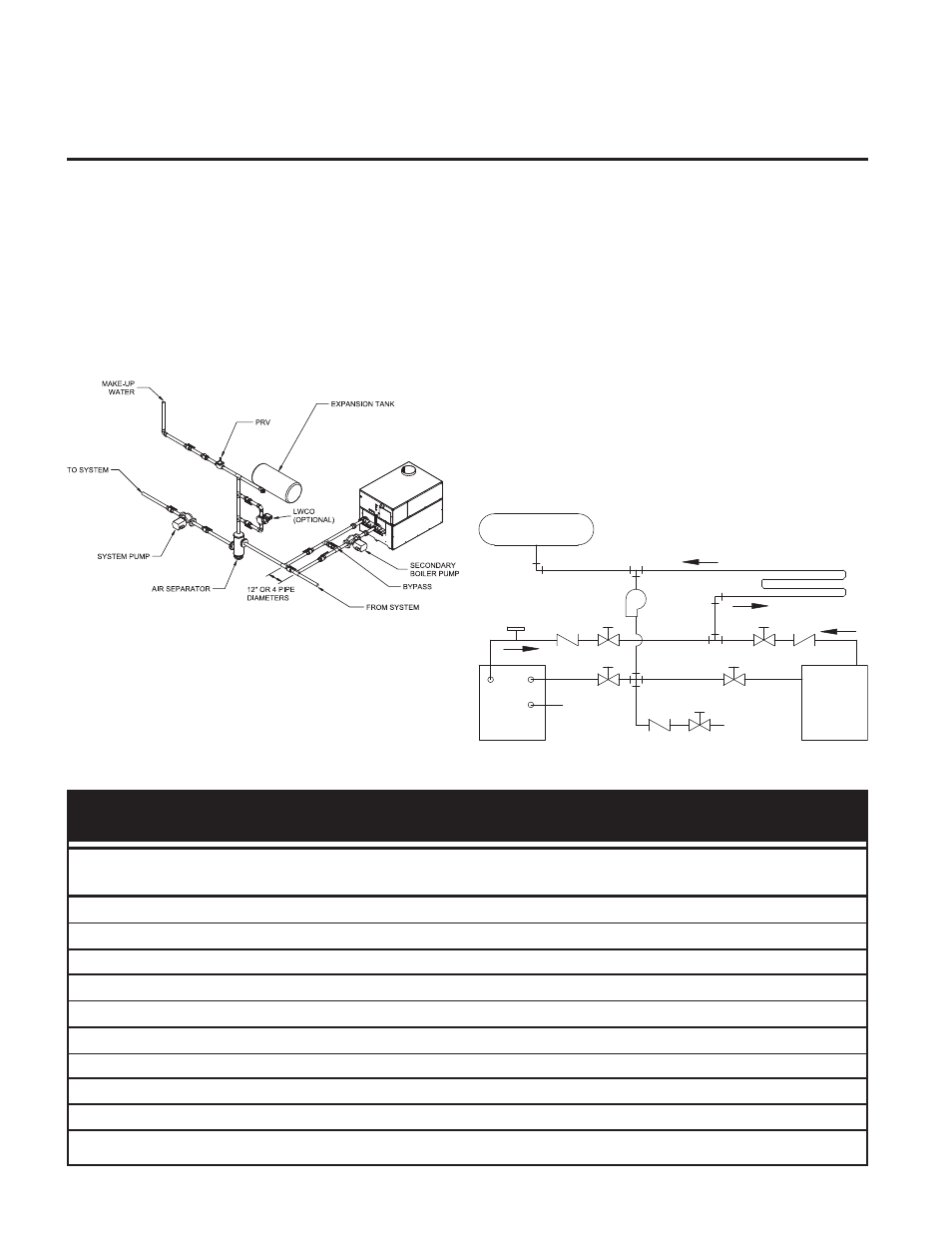

Figure 28 - Boiler with Low Temperature Bypass Piping

Installation with a Chilled Water

System

Pipe refrigeration systems in parallel. Install duct coil

downstream at cooling coil. Where the hot water heating boiler

is connected to a heating coil located in the air handling units

which may be exposed to refrigeration air circulation, the

boiler piping system must be equipped with flow control

valves or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle. The coil must be

vented at the high point and hot water from the boiler must

enter the coil at this point. Due to the fast heating capacity of

the boiler, it is not necessary to provide a ductstat to delay

circulator operation. Also, omit thermostat flow checks as the

boiler is cold when heating thermostat is satisfied. This

provides greater economy over maintaining standby heat (see

Figure 29).

Figure 29 - Installation with a Chilled Water System

Hydronic Heating Boilers and

Domestic Water Heaters

26

System Temperature Risased on Btu/hr Input

T

T

T

T

T

T

10ºF

20ºF

30ºF

40ºF

50ºF

60ºF

Input

Output

GPM FT. HD GPM FT.HD

GPM FT.HD

GPM FT.HD

GPM FT.HD

GPM FT.HD

495,000

400,950

80+

*

40

4.0

27

1.6

20

0.7

16

0.6

13

0.6

645,000

522,450

129+

*

52

5.1

35

3.0

26

1.6

21

0.8

17

0.6

745,000

603,450

149+

*

60

*

40

4.0

30

2.3

24

1.2

20

0.7

985,000

831,600

197+

*

80

5.2

53

2.4

40

1.4

32

1.0

27

0.8

1,255,000

1,058,400

251+

*

102+

*

68

4.3

51

2.5

41

1.6

34

1.1

1,435,000

1,209,000

288+

*

116+

*

78

6.0

58

3.7

47

2.2

39

1.7

1,795,000

1,512,000

360+

*

146+

*

97+

*

73

6.2

58

4.2

49

2.4

2,065,000

1,738,800

414+

*

168+

*

112+

*

84

8.7

67

6.0

56

4.5

+ These flow rates exceed recommended flow rates of boiler. If these system temperature rises are used, an external piping by-pass must be installed.

* These foot head calculations exceed the maximum allowable flow rate of the boiler. Requires Cupro-Nickel heat exchanger.

TABLE - L

System Temperature Rise Chart Based on Btu/hr Input

EXPANSION

TANK

CHILLER

BOILER

IN

OUT

SUPPLY

GAS

WATER

SUPPLY

LOW WATER

FLOW SWITCH

COOLING COIL

HEATING AND

PUMP