Installation – Lochinvar 000 - 2 User Manual

Page 18

INSTALLATION

Continued

Water heater models do not have downstream test valves, but

the rest of the gas train is represented by Figure 19.

Combination Gas Valves

These units fire in up to 2 stages of burner input. Each stage of

burner operation has a combination gas valve or series of gas

valves to cycle the gas supply on and off and regulate gas to the

burners. Each combination valve consists of a gas regulator and

two valve seats to meet the requirements for redundant gas

valves. The valve has a gas control knob that must remain in the

open position at all times when the unit is in service. The gas

control valve has pressure taps located on the inlet and discharge

sides of the valve. Manifold pressure is adjusted using the

regulator located on the valve. A manifold gas pressure tap for

each burner stage is located on the discharge side of the valve.

The manifold pressure is preset at the factory and adjustment

is not usually required. If you must adjust regulator pressure,

follow the instructions under Gas Manifold Pressure

Adjustment, page 19.

Venting of Combination Gas Valves

The combination gas valve/regulator used on all units is

equipped with an integral vent limiting orifice per ANSI

Z21.78. The vent limiter ensures that the volume of gas

emitted from the valve does not exceed the maximum safe

leakage rate allowed by agency requirements. Combination

gas valve/regulators equipped with integral vent limiters are

not required to have vent or relief lines piped to the outdoors.

The termination of the vent limited opening on the

combination gas valve/regulator complies with the safety code

requirements of CSD-1, CF-190(a) as shipped from the

appliance manufacturer without the installation of additional

vent lines.

Checking Gas Supply Pressure

Use the following procedure to check gas supply pressure.

1. Turn the main power switch to the "OFF" position.

2. Turn gas valve knobs to the "OFF" position.

3. Shut off gas supply at the field-installed manual gas cock

in the gas piping to the unit. If fuel supply is L.P. gas, shut

off gas supply at the tank.

4. Remove the 1/8" hex plug, located on “inlet” side of the

gas valve. You may also use a tapping on the field-installed

main manual gas cock or gas piping. Install a fitting in the

inlet pressure tapping suitable to connect to a manometer

or magnahelic gauge. Range of scale should be 14" w.c. or

greater to check inlet pressure.

5. Turn on gas supply at the manual gas cock, turn on L.P. gas

at tank if required.

6. Turn the power switch to the “ON” position.

7. Turn the gas valve knobs to the “ON” position. Set the

electronic temperature control or thermostat to call for

heat.

8. Observe the gas supply pressure as all burners are firing.

Ensure that inlet pressure is within the specified range. See

Connecting To Gas Supply, page 16 for minimum and

maximum gas supply pressures.

Hydronic Heating Boilers and

Domestic Water Heaters

18

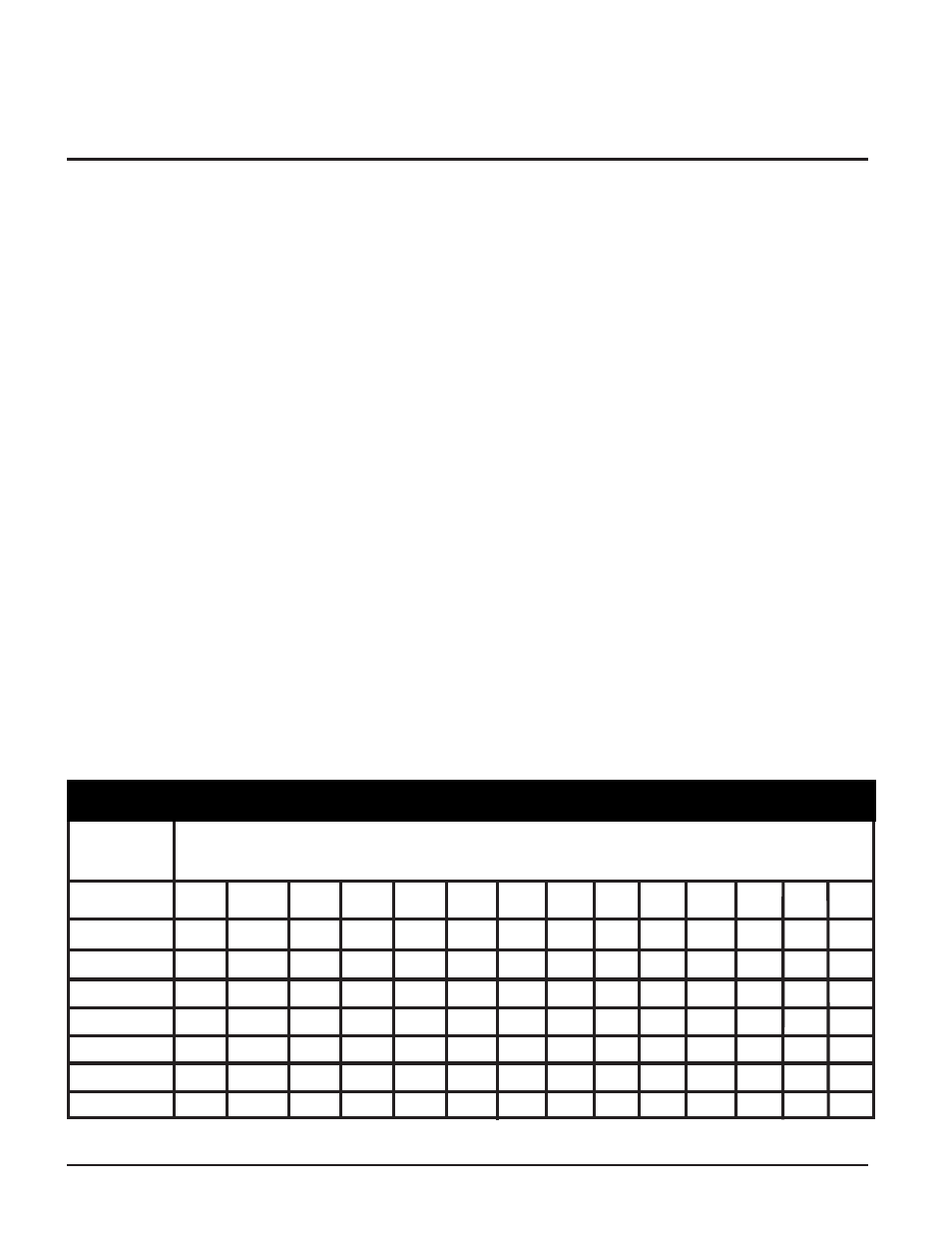

Nominal Iron

Length of Pipe In Straight Feet

Pipe Size,

(Inches)

10

20

30

40

50

60

70

80

90

100

125

150

175

200

TABLE - H

Multiple Unit Installations Gas Supply Pipe Sizing

3/4

"

369

256

205

174

155

141

128

121

113

106

95

86

79

74

1"

697

477

384

328

292

267

246

226

210

200

179

164

149

138

1 1/4

"

1,400

974

789

677

595

543

502

472

441

410

369

333

308

287

1 1/2

"

2,150

1,500

1,210

1,020

923

830

769

707

666

636

564

513

472

441

2"

4,100

2,820

2,260

1,950

1,720

1,560

1,440

1,330

1,250

1,180

1,100

974

871

820

2-1/2"

6,460

4,460

3,610

3,100

2,720

2,460

2,310

2,100

2,000

1,900

1,700

1,540 1,400

1,300

3"

11,200

7,900

6,400

5,400

4,870

4,410

4,000

3,800

3,540

3,300

3,000

2,720 2,500

2,340

4"

23,500

16,100

13,100

11,100

10,000

9,000

8,300

7,690

7,380

6,870

6,150

5,640 5,130

4,720

Maximum capacity of pipe in thousands of BTU’s per hour for gas pressures of 14 Inches Water Column (0.5 PSIG) or less and a total system

pressure drop of 0.5 Inch Water Column (Based on NAT GAS, 1025 BTU’s per Cubic Foot of Gas and 0.60 Specific Gravity).