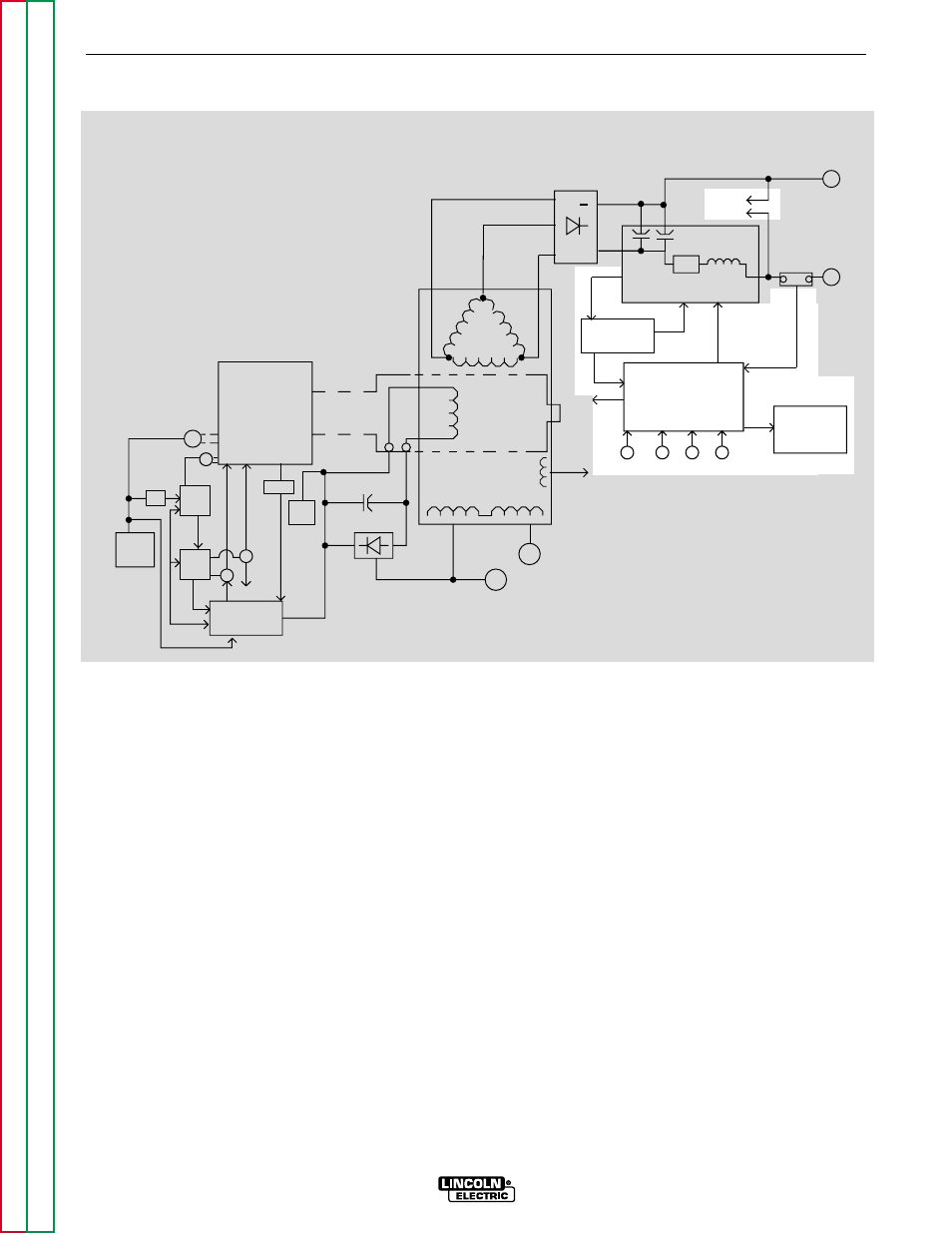

Commander 500, Theory of operation, Engine rotor stator – Lincoln Electric COMMANDER SVM153-A User Manual

Page 50: Weld control board

ANALOG CONTROL POWER

SUPPLY BOARD AND WELD

CONTROL BOARD

The Analog Power Supply PC board, which is powered

by 80 VDC derived from the filter capacitors on the

Power Modules, supplies various regulated DC volt-

ages to operate the Weld Control PC board circuitry. It

also supplies two regulated DC voltages to operate the

IGBT driver circuitry on the two Power Modules.

The Weld Control PC board monitors the operator con-

trols (arc control, output, and process/range selector).

It compares these commands to the current and volt-

age feedback information it receives from the shunt

and output terminal circuits. The circuitry on the Weld

Control PC board determines how the output should be

controlled to optimize welding results, and it sends the

correct PWM signals to the IGBT driver circuits. The

Weld Control PC board also commands the thermal

light and the voltmeter and ammeter (some items may

be optional).

E-4

E-4

THEORY OF OPERATION

COMMANDER 500

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

ENGINE

ROTOR

STATOR

AUXILIARY

WINDINGS

W

E

L

D

W

I

N

D

I

N

G

MECHANICAL

ROTATION

STARTER

ALTERNATOR

ENGINE

SENSORS

OUTPUT

PROCESS/RANGE

1

2

0

V

A

C

120VAC

RECEPTACLES (2)

240VAC

RECEPTACLE

SLIP

RINGS

ANALOG

POWER SUPPLY

BOARD

ARC

WELD

CONTROL

BOARD

CONTROL CONTROL

SELECTOR

PWM

SIGNALS (2)

VOLTMETER

AMMETER

BATTERY

S

H

U

T

D

O

W

N

I

D

L

E

R

PERIPHERAL

BOARD

BATTERY

BOARD

PULL

COIL

BOARD

SOL

SOL

TO

IDLE

HOLD

COIL

42 VAC TO 14 PIN AMPHENOL

THREE-PHASE

RECTIFIER

CHOKE

IGBT

WORK

TERMINAL

ELECTRODE

TERMINAL

+

+

SHUNT

F

E

E

D

B

A

C

K

__

__

POWER MODULES

(2)

TO WELD

CONTROL

BOARD

FOR WIRE FEEDER

COMMANDER 500

(2)

(2)

80 VDC

(2)

20 VDC

THERMAL

LIGHT

TO WELD

CONTROL

BOARD

10

VDC

10

VDC

120

VDC

1/2

BATTERY

BD

RUN/STOP

SWITCH

FIGURE E-4 – ANALOG CONTROL POWER SUPPLY BOARD AND WELD CONTROL BOARD