Installation with a chilled water system, Boiler operating temperature control – Lochinvar 000 through 2 User Manual

Page 69

69

Boiler Operation

28.

Turn the run/stop switch to the “RUN” position to

start boiler operation.

29.

Push the resets for low water lev

el, high water

temperature and flame failure.

30.

Observe the boiler synchronization process before

start-up of the boiler begins.

31.

Boiler should begin the start-up process for the

sequence of operation.

32.

The boiler will fire at 50% of rated input on initial

start-up and adjust input as required to meet

system demand.

33.

The integral bypass valve will automatically adjust

to maintain min

i

mum inlet temperatures to the

primary heat exchanger.

34.

Ensure that inlet water temperature does not fall

below the specified min i mum for the boiler.

35.

Based on system demand, the boiler may run for

an extended period of time at a reduced rate of

input to maximize efficiency.

36.

As system demand is satisfied, the burner will

cycle off and the com

bus

tion air blower will run

for a post purge operation before the boiler shuts

down.

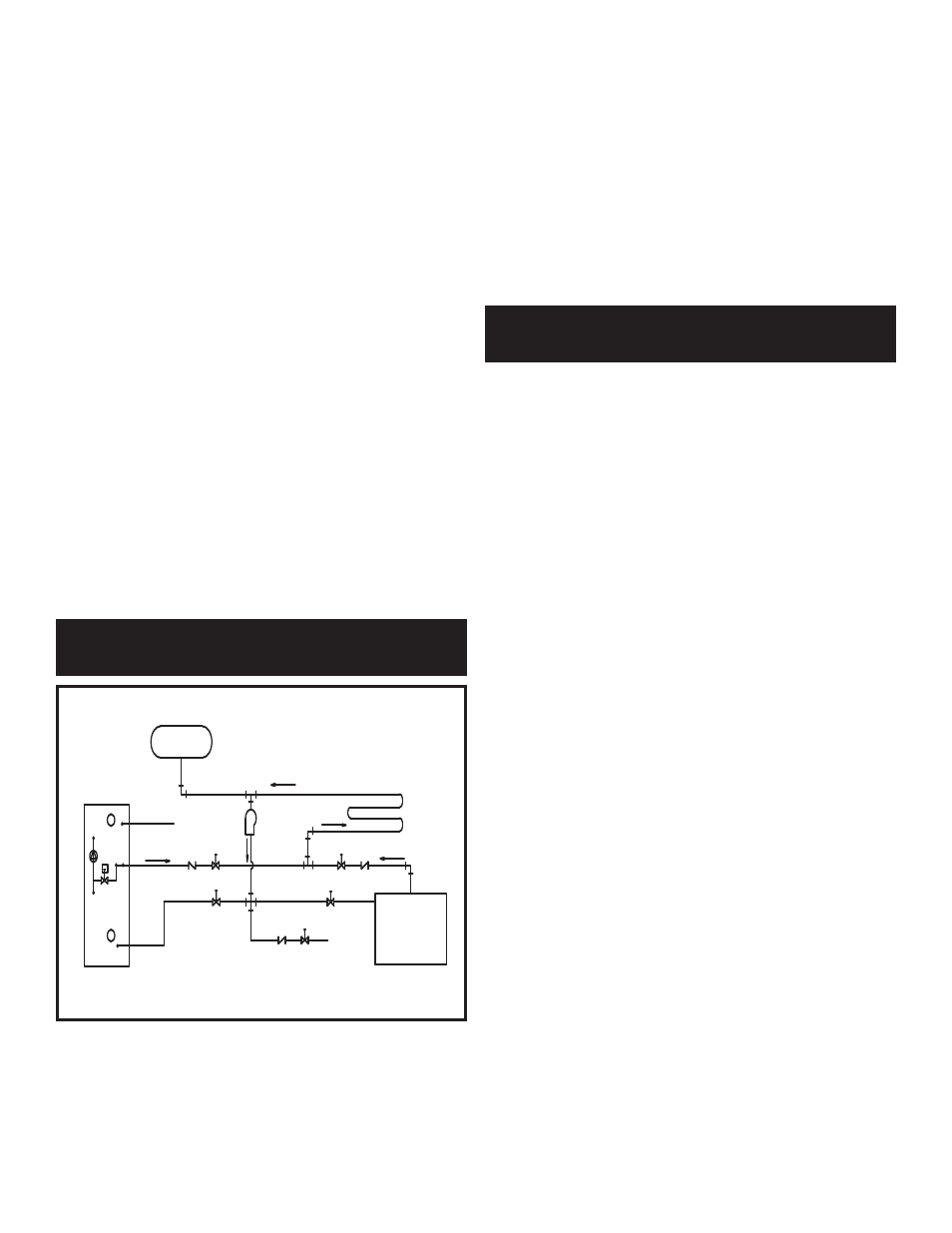

INSTALLATION WITH A

CHILLED WATER SYSTEM

EXPANSION

TANK

HEATING AND

COOLING COIL

GAS SUPPLY

PUMP

WATER

SUPPLY

CHILLER

FIG. 82 Installation with a Chilled Water System

Pipe refrigeration systems in parallel. Install duct coil downstream

at the cooling coil. Where the hot water heating boiler is connected

to a heating coil located in the air handling units which may be

exposed to refrigeration air circulation, the boiler piping system

must be equipped with flow control valves or other automatic

means to prevent gravity circulation of the boiler water during the

cooling cycle. The coil must be vented at the high point and hot

water from the boiler must enter the coil at this point. Due to the

fast heating capacity of the boiler, it is not necessary to provide a

ductstat to delay circulator op er a tion. Also, omit thermostat flow

checks as the boiler is cold when heat ing thermostat is satisfied.

This provides greater economy over main tain ing standby heat.

BOILER OPERATING

TEMPERATURE CONTROL

The operating temperature control for the boiler is the Excel 10

controller. It is located on the back side of the front control panel,

behind the front access door. Access to adjust the temperature set

point and other owner/operator adjustable points is made through

the Command Display located on the front control panel. The

sensing element for the operator is placed in a bulb well installed

in the inlet connection to the boiler. The outlet sensor is located in

a bulb well on the outlet side of the primary heat exchanger top

header. Carefully observe the discharge water temperature on the

initial boiler on cycles. The location of the tem per a ture sensor may

generally require a lower temperature set point on the operating

control to achieve the de sired discharge water temperature from the

boiler. The return/inlet sensing element lo ca tion allows a boiler to

sustain longer burner on cycles.

The location of the operating sensor, inlet or outlet, is selectable

from the screen on the Command Display.

The exact temperature set point is based on your system’s

requirements. Set the control set point(s) to the desired operating

water temperature. Observe the boiler discharge tem per a ture after

each set point adjustment to ensure proper operation.

The maximum set point for operation of a heating boiler is

220°F (104.4°C) on a standard Excel 10 control. The minimum

tem per a ture setting programmed into this stan dard Excel 10

control is 100°F (37.7°C).