Hot surface ignition system – Lochinvar 000 through 2 User Manual

Page 49

49

HOT SURFACE IGNITION SYSTEM

IGNITION CONTROL MODULE

DIAGNOSTIC STATUS CODES

FIG. 63 Hot Surface Ignition Control Module

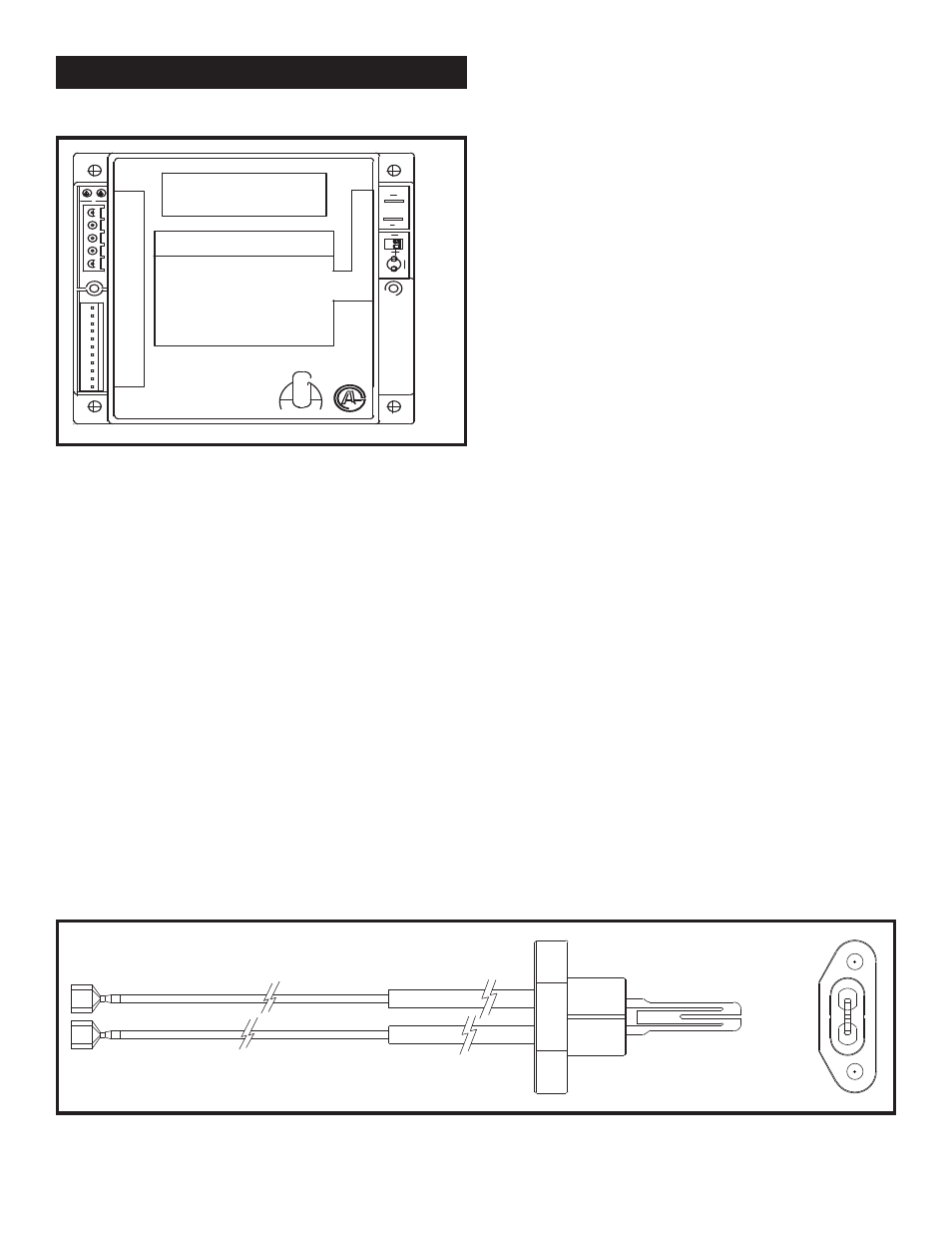

FIG. 64 Hot Surface Igniter

This appliance uses a proven hot sur face ignition control system.

The operation of the electronic control module for the hot surface

igniter proves the presence of an ignition source much like a proven

standing pilot before the gas valves are energized. The ignition

control module starts and proves the operation of the combustion air

blower, proves the presence of the proper ignition temperatures

from the hot surface igniter, energizes the main gas valves, proves

the presence of main burner flame, provides for soft lock outs on

control sensed faults, provides a hard lockout on flame failure and

controls the pre and post purge timings of the combustion air

blower. A status point alarm of FlameFail will be dis played in the

Command Display on a hard lockout for flame failure.

Service Parts

This appliance uses a proven electronic ignition control module and

a hot sur

face igniter. The electronic ignition module is not

repairable. Any mod i fi ca tion or repairs will invalidate the warranty

and may create hazardous con di tions that result in property damage,

personal injury, fire, explosion and/or toxic gases. A faulty hot

surface igniter or ignition module MUST be replaced with a new

OEM unit only. An OEM specification igniter and ignition control

module for this specific unit is available from your local dis tributor.

DO NOT use general purpose field replacement ignition modules

or ig nit ers. Each appliance has one ignition module and one hot

surface igniter.

Ignition Module Lockout Functions

The ignition module may lockout in either a hard lockout condition

re quir ing pushing of the reset button to recycle the control or a soft

lockout condition which may recycle in a fixed time period to check

for correction of the fault condition. A typical hard lockout fault is

a flame failure con di tion. Pushing the reset button for the ignition

control is the only way to reset an ignition module that is in a hard

lockout condition. The reset button is located on the inside front

control panel. The reset button is active after the post purge cycle

when there is a hard lockout condition as indicated by the Status

LED. Turning the main power “OFF” and then “ON” or cy cling the

thermostat will not reset a hard lockout condition. Wait five

seconds after turning on the main power before pushing the reset

button when the ignition module is in a hard lock out. The ignition

module will go into a soft lockout in conditions of low air, low

voltage or low hot surface igniter current. A soft lockout con di tion

will operate the combustion air blower for the post purge cycle and

then the ignition module will pause for a fixed time period. The

timed length of the pause is based on the type of fault sensed by

the control module. At the end of this timed pause, the ig ni tion

module will attempt a new trial for ignition sequence. If the soft

lockout fault condition has subsided or has been corrected at the

end of the timed pause, main burner ignition should be achieved

with the resumption of the normal trial for ignition

se quence. If the control sensed fault is not corrected, the ignition

module will continue in the soft lockout condition. If the electronic

thermostat opens during the soft lockout period, the ignition module

will exit soft lockout and wait for a new call for heat from the

thermostat. A soft lockout con di tion may also be reset by manually

cycling the electronic thermostat or turning the main power switch

“OFF” and then “ON” after the control sensed fault has been

corrected. SoftLockout will be shown in the screen of the

Command Display when the ignition con trol module has gone into

a soft lock out condition.