Primary heat exchanger, Secondary heat exchanger – Lochinvar 000 through 2 User Manual

Page 28

28

Inlet and Outlet Connections

For ease of service, install unions on inlet and outlet of the

appliance. The connection to the appliance marked “Inlet” on the

header should be used for return from the system. The

con nec tion on the header marked “Outlet” is to be connected to

the supply side of the system.

Minimum Pipe Size Requirements

Minimum water pipe connections to this appliance is 3 inch

(76.2 mm) pipe for single unit installations installed not more

than 70 equivalent feet (21.3 m) of pipe from the main system

loop or storage tank. The equivalent number of straight feet of

pipe for each valve and fitting in the connecting piping must be

considered to properly arrive at the total equivalent feet of

straight pipe in the field installed piping to the appliance. See

the pip ing requirements in the heating boiler or water heater

section of this manual. Consult factory if longer piping dis tances

are required for a specific application.

PRIMARY HEAT EXCHANGER

FIG. 38 Primary Heat Exchanger

This appliance uses two finned copper tube heat exchangers to

maximize the heat transfer process. The primary heat exchanger

is mounted in the inner jacket on the front side of the ap pli ance.

The primary heat exchanger is composed of two circular glass

lined cast iron headers with 24 vertical finned copper tubes. A

series of “V” shaped baffles are installed between the individual

tubes to control

the movement of the flue products over the finned copper surface

and increase heat transfer. Water enters the primary heat exchanger

and makes four passes over the area exposed to direct heat from

the burner. An internal cir cu lat ing pump ensures proper water flow

over the heat transfer surfaces during burn er operation. Water

temperatures in the primary heat exchanger are con trolled by the

operation of the au to mat ic bypass assembly. Operation of the

bypass maintains water temperatures above 130°F (54.4°C) in the

primary heat exchanger to prevent flue gas condensation on the

primary heat ex chang er surfaces.

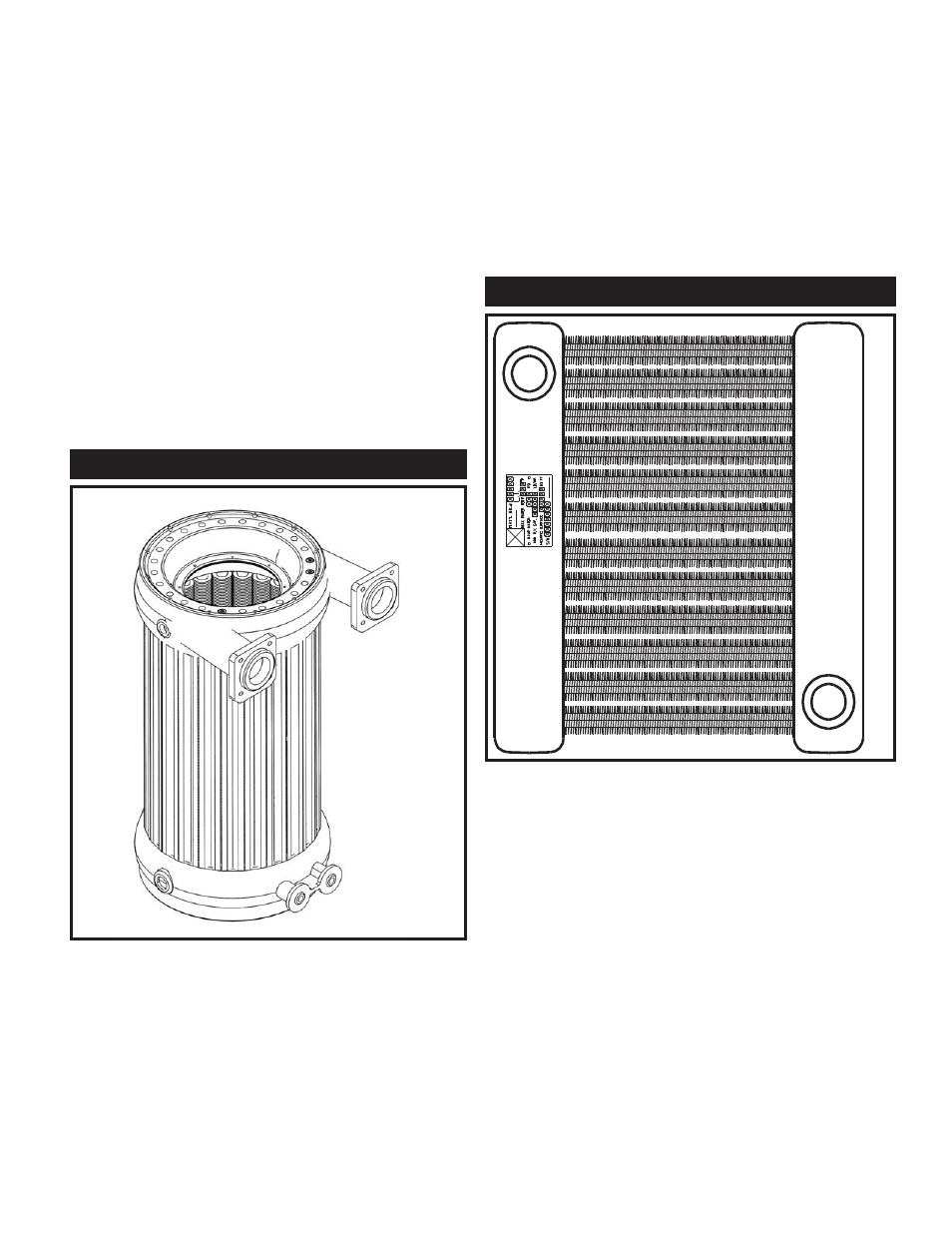

SECONDARY HEAT EXCHANGER

FIG. 39 Secondary Heat Exchanger

A secondary heat exchanger is mounted in an inner jacket chamber

at the rear of the appliance. The secondary heat exchanger is

constructed from two glass lined cast iron headers and multiple hor -

i zon tal finned copper tubes. The secondary heat exchanger is

mounted in the dis charge of the flue products from the primary heat

exchanger. This allows additional heat to be absorbed from the flue

products exhausted from the com bus tion process. The return water

from the system passes through the secondary heat exchanger

before it enters the primary heat exchanger. This allows the coolest

return water temperatures to enter the secondary heat exchanger

before proceeding to the primary heat exchanger. When return

water tem per a tures are below approximately 130° F (54.4°C), the

flue products passing over the secondary heat exchanger may be

cooled below their dewpoint re

sult

ing in the formation of

condensate. The secondary heat exchanger has a special high