Masonry chimney installations, Caution ƽ, Vertical venting terminations – Lochinvar 000 through 2 User Manual

Page 11

11

the tee. The drain tubing must have a trap provided by a 4"

(10.2 cm)-diameter circular trap loop in the drain tubing. Prime

the trap loop by pouring a small quantity of water into the drain

hose before assembly to the vent. Secure the trap loop in position

with nylon wire ties. Use caution not to collapse or restrict the

condensate drain line with the nylon wire ties. The con den sate

drain must be routed to the con den sate neutralization system or a

suitable drain for disposal of con den sate that may occur in the

Category IV vent system. Refer to the condensate drain

installation instructions as supplied by the manufacturer of the vent

material. Ensure that the drain from the condensate tee is not

exposed to freezing temperatures. See “Freeze Protection” for

more information.

MASONRY CHIMNEY

INSTALLATIONS

A standard masonry chimney must NOT be used to vent the

products of combustion from the flue of a Category IV,

pos i tive pressure appliance. If a masonry chimney is to be used,

the chimney MUST use a sealed, metallic, corrosion

re sis tant liner system to vent flue products from this high

efficiency appliance. Sealed, metallic, corrosion resistant liner

systems (single wall, double-wall, or flexible or rigid metallic

liners) must be rated for use with a high efficiency Category IV,

positive pressure vent system. Corrosion re sis tant chimney liner

systems are typ i cal ly made from a high grade of cor ro sion resistant

stainless steel such as AL 29-4C. The corrosion resistant liner must

be properly sized and fully sealed throughout the entire length if

the flue is contained within the masonry chimney. Both the top and

the bottom of the masonry chimney must be capped and sealed to

provide a dead air space around the sealed corrosion resistant

metallic liner. Consult with local code officials to determine code

re quire ments or the advisability of using a masonry chimney

with a sealed cor ro sion resistant liner system.

CAUTION

ƽ

Venting of a high efficiency Category IV appliance into a

masonry chimney without a sealed stainless steel liner can

result in operational and safety problems. Any breaks, leaks

or damage to the masonry flue/tile will allow spillage of the

positive pressure flue products from the chimney. These

flue products can easily escape into an occupied living

space causing a health hazard. If there is any doubt about

the condition of a masonry chimney, or its acceptability for

use after inser tion of a corrosion resistant liner system,

consult with local code officials.

VERTICAL VENTING

TERMINATIONS

Follow all General Category IV Vent Termination Clearances.

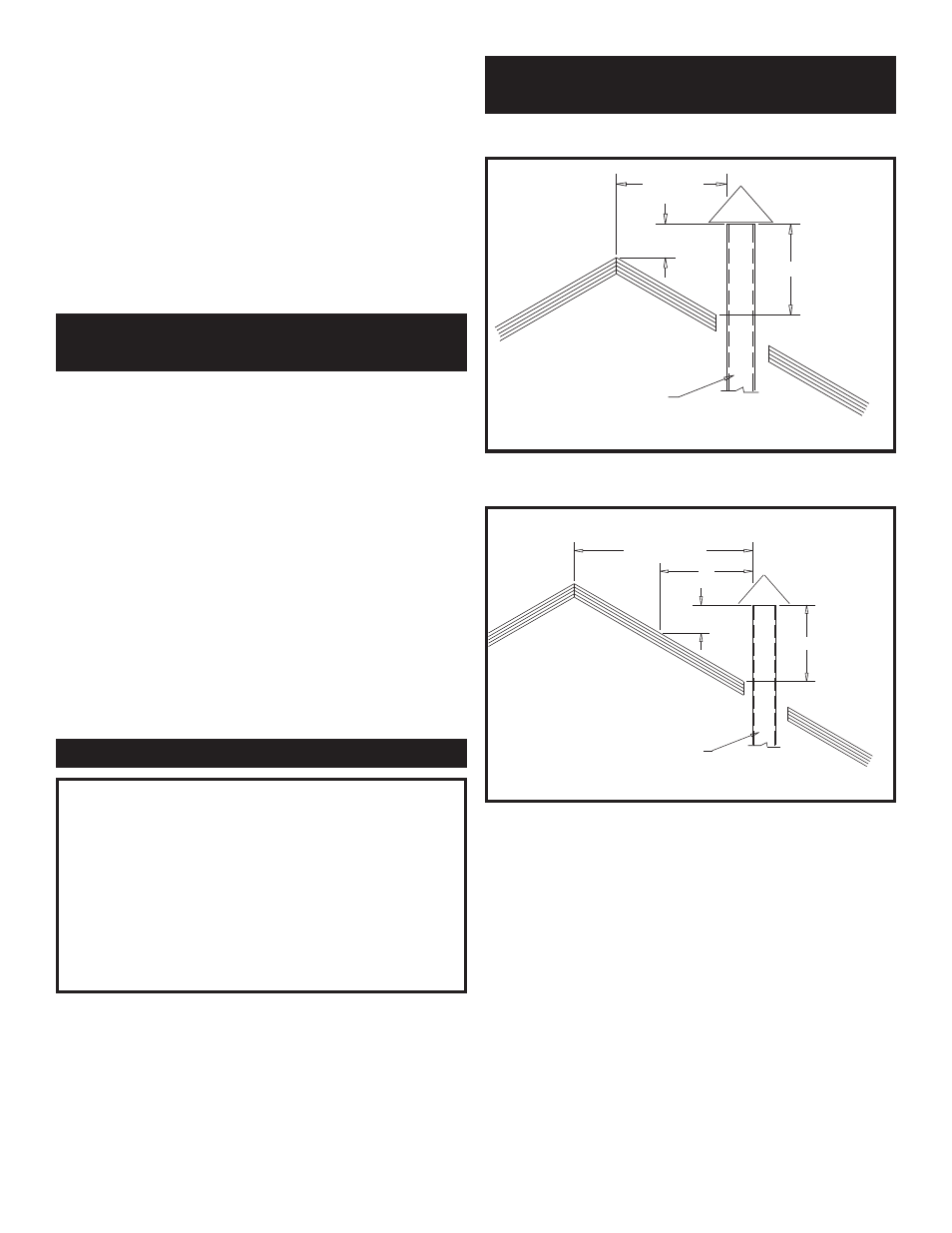

RIDGE

CHIMNEY

3' MIN

2' MIN

10' OR LESS

FIG. 13 Vent Termination from Peaked Roof - 10 Feet or Less

from Ridge

RIDGE

CHIMNEY

3' MIN

2' MIN

MORE THAN 10'

10'

FIG. 14 Vent Termination from Peaked Roof - 10 Feet or

More from Ridge

The vent terminal should be vertical and exhaust outside the build-

ing at least 2 feet (0.61 m) above the highest point of the roof within

a 10 foot (3.05 m) radius of the termination.

The vertical termination must be a minimum of 3 feet (0.91 m)

above the point of exit.