Loctite CARTESIAN 400 User Manual

Page 75

Also, Program Number can be set using expressions.

Example)

declear num eprg

waitCondTime 200

ld #genIn1

timeUp

if

ld #genIn2

then

eprg = 9

else

eprg = 10

endIf

callProg eprg

endWait

Declare the local variable “eprg.”

Wait for 0.2 sec until the following condition is met.

#genIn1=ON (Condition)

If the conditions are not met within 0.2 sec,

If

#genIn2=ON

then

Assign 9 to “eprg.”

If not,

Assign 10 to “eprg.”

Call a subroutine of Program number 9/10.

Point Data Setting

[Position Data] of the program data defines how to handle coordinates (position data) in the point

data. It consists of the following three types.

Absolute Coordinates: position data value is deemed as the fixed coordinates of the robot.

Relative Coordinates: position data value is deemed as the distance from coordinates to where

the program starts.

Moving Amount: position data value is deemed as the distance to the next point.

If you set the subprogram to [Relative] or [Moving Amount], the tool unit always runs at an equal

distance from the called point (to where point job data including “callProg” command is assigned.)

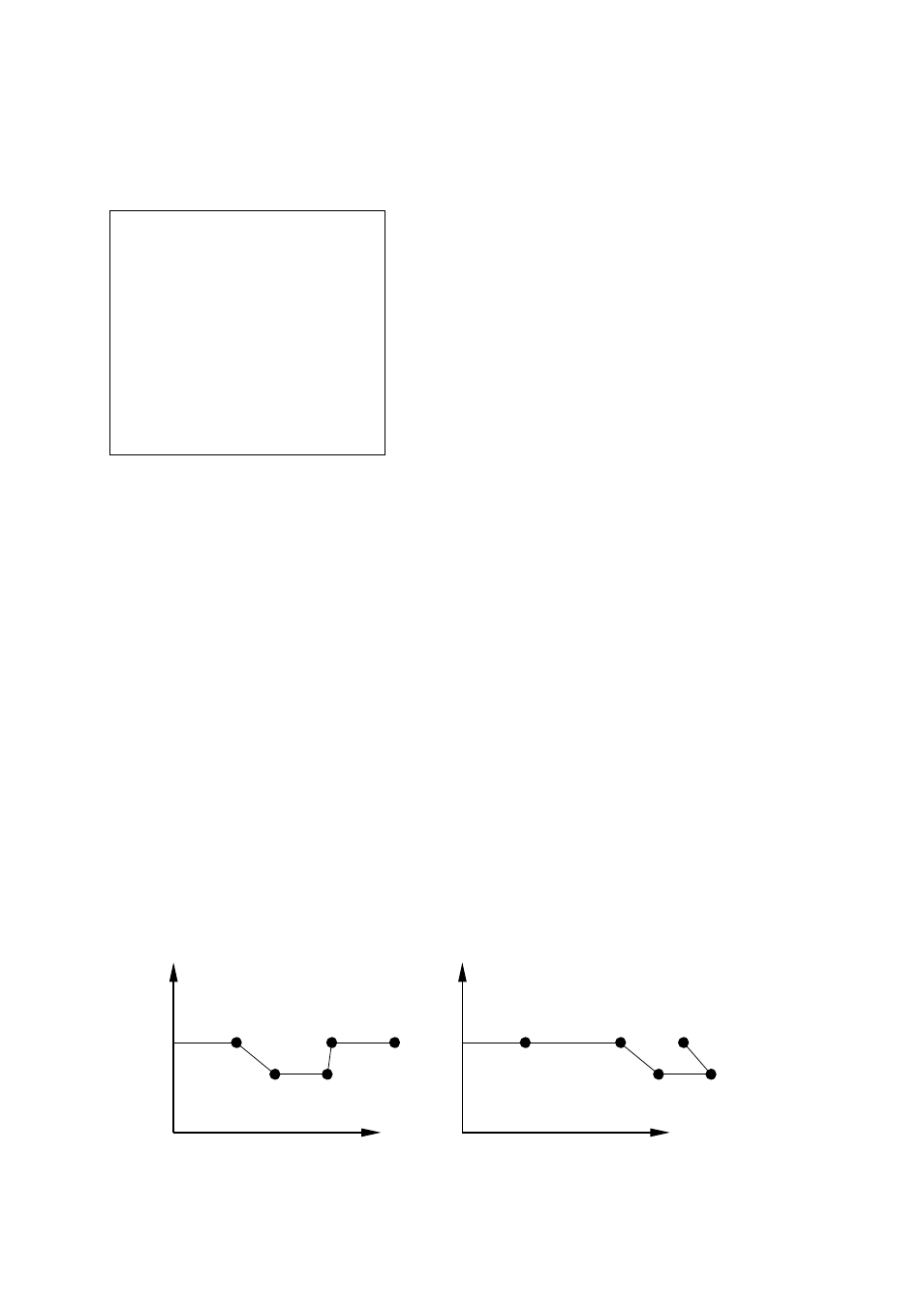

Example: The subprogram is set to [Relative] or [Moving Amount.]

The current point (called point) is P1 (SP1) (excluding P1 coordinate data in the subprogram.)

The work home position is ignored.

Calling Point

P6

SP1

SP2

SP3

P7

P8

Calling Point

P7

SP1

SP2

SP3

P6

P8

Features II CARTESIAN Benchtop Robot

57