Konica Minolta CF5001 User Manual

Page 82

CF5001 Ver.1.0 Sep. 2003

TRANSFER BELT UNIT

2-29

II UNIT EXPLANA

TION

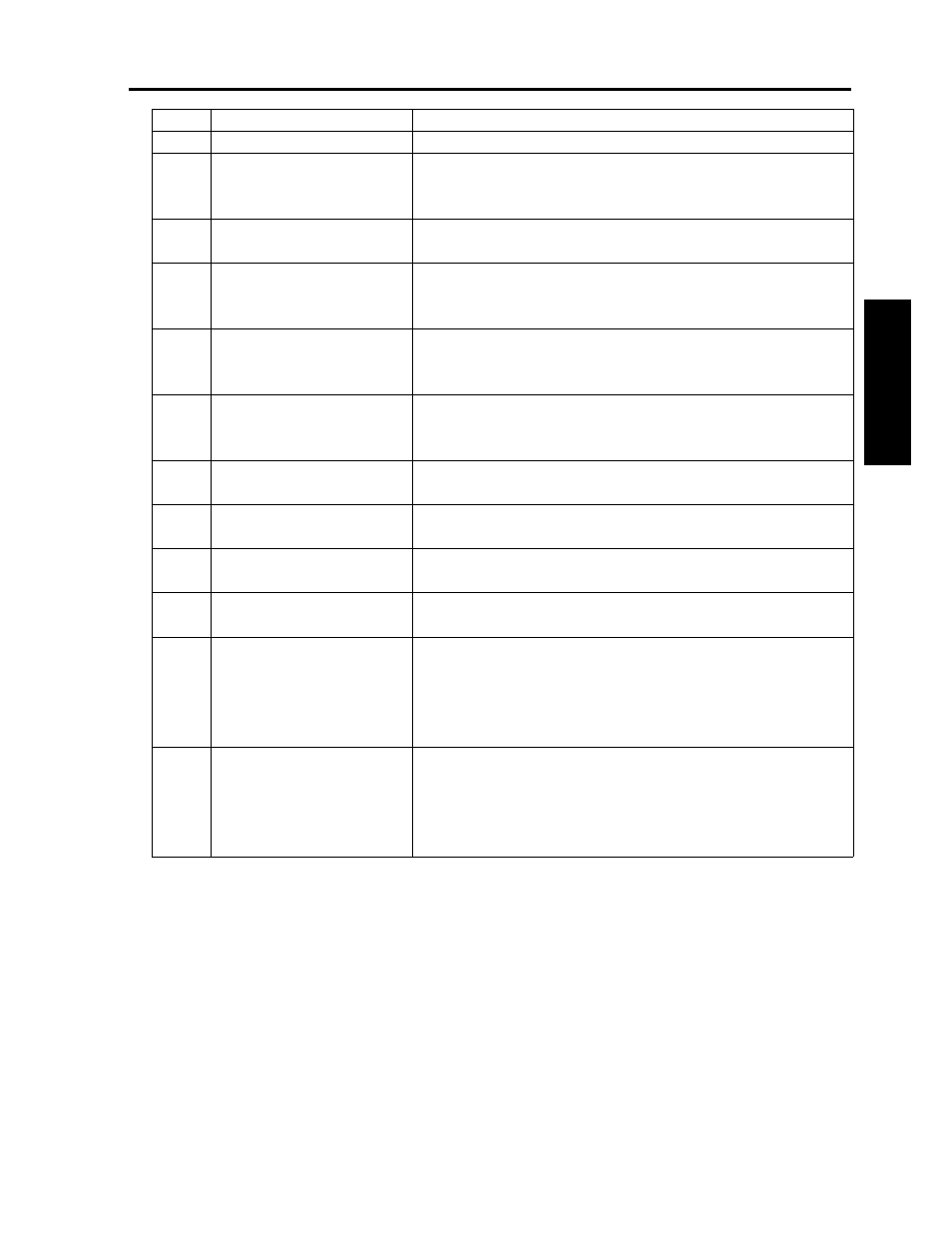

[9]

Toner guide brush

Scraping and collection of toner on the transfer belt

[10]

Toner collection screw

Conveys toner from the belt cleaning section to the toner collec-

tion section

Screw method

[11]

Image correction unit

Detection of variety of information of images transferred on the

transfer belt

[12]

Transfer belt separation claw

Paper separation assist from the transfer belt

Pressure/release method by the transfer belt separation claw sole-

noid (SD1)

[13]

2nd transfer roller /U

Toner transfer from the transfer belt to paper

Constant current DC bias applied roller method

DC output range by constant current method: +30 to -120

µA

[14]

2nd transfer roller /L

(Provided on ADU side)

Toner transfer from the transfer belt to paper

Pressure/release mechanism by means of cam

Driven idly by the transfer belt

M18

Transfer belt motor

Driving of the transfer belt

DC brushless motor, PLL control

M19

1st transfer pressure/release

motor

Pressure/release of the 1st transfer roller /Y, /M, /C, /K

Stepping motor

SD1

Transfer belt separation claw

solenoid

Pressure/release of the separation claw

24 VDC drive

PS15

1st transfer HP sensor

Pressure/release mechanism of the 1st transfer roller /Y, /M, /C, /K

Home position detection

PS68

Encoder sensor/belt 1

Detection of the rotation of encoder for the transfer belt drive shaft

Drive control of the transfer belt motor (M18)

2 sensors of the PS68 and PS69 are provided at the opposite

position of the encoder to cancel the change of rotation caused by

the eccentricity of the encoder.

PS69

Encoder sensor/belt 2

Detection of the rotation of encoder for the transfer belt drive shaft

Drive control of the transfer belt motor (M18)

2 sensors of the PS68 and PS69 are provided at the opposite

position of the encoder to cancel the change of rotation caused by

the eccentricity of the encoder.

Symbol

Name

Function or method