10 transfer belt cleaning (sub step 3), 11 2nd transfer roller/l cleaning (sub step 4), 11 2nd transfer roller /l cleaning (sub step 4) – Konica Minolta CF5001 User Manual

Page 51

IMAGE CREATION PROCESS

CF5001 Ver.1.0 Sep. 2003

1-28

I OUTLINE

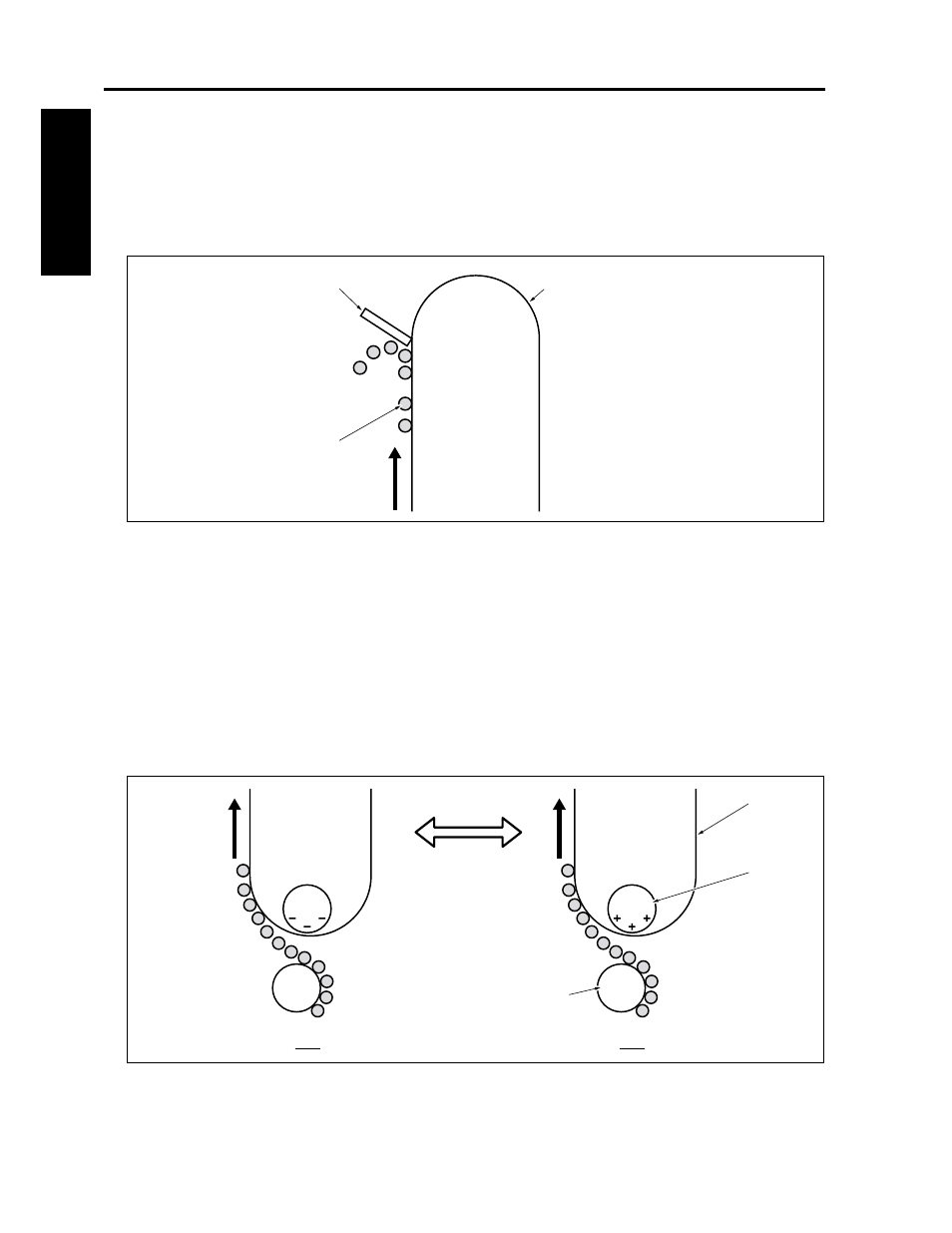

6.10 Transfer belt cleaning (Sub step 3)

A transfer belt that has completed the 2nd transfer has a residual amount of toner that is left from the trans-

fer process. The process to remove toner is referred to as a transfer belt cleaning.

A transfer belt cleaning is made by scraping toner adhered to the drum surface with the edge of a plate

called a blade that is made of urethane rubber.

6.11 2nd transfer roller /L cleaning (Sub step 4)

Residual toner on the transfer belt is in direct contact with the 2nd transfer roller /L. As a result, the 2nd

transfer roller /L may be coated with toner.

So, the 2nd transfer roller /U is applied with a positive and a negative high DC bias voltage alternately to

move toner on the 2nd transfer roller /L to the transfer belt side. The toner on the transfer belt that has

been moved is cleaned by the transfer belt cleaning mentioned above.

[1]

Transfer belt

[3]

Cleaning blade

[2]

Residual toner

[1]

Transfer belt

[4]

DC bias (positive) applied

[2]

2nd transfer roller /L

[5]

DC bias (negative) applied

[3]

2nd transfer roller /U

8050ma1026

[1]

[3]

[2]

[4]

[5]

[2]

[1]

[3]

8050ma1027