Status led’s, Wiring and connections, Rs232 port pin out – Siemens PAPBH User Manual

Page 2: Profibus connection, Troubleshooting

2

6. CERTIFICATIONS AND COMPLIANCES:

SAFETY

IEC 1010-1, EN 61010-1: Safety requirements for electrical equipment for

measurement, control, and laboratory use, Part 1.

ELECTROMAGNETIC COMPATIBILITY

Note:

1. Self-recoverable loss of performance during EMI disturbance at 10 Vrms:

For operation without loss of performance:

Install 1 ferrite core RLC #FCOR0000 or equivalent, to power cable at unit.

I/O cables are routed in metal conduit connected to earth ground.

7. FIELD CONNECTIONS: Removable screw terminal blocks.

8. WEIGHT: 1.25 lb (0.58 kg)

STATUS LED’s

Three LED’s provide status indication and are described in Table 1. The

PROFIBUS–DP state machine is indicated by the data, WD and DP LED’s and

are described in Table 2.

Table 1

Paradigm PROFIBUS Host Adapter Status LED Description

Table 2

Led Indication of Paradigm PROFIBUS Host Adapter State

In PROFIBUS-DP Slave State Machine

WIRING AND CONNECTIONS

POWER SUPPLY REQUIREMENTS

The Operator Interface requires an 11 to 30 VDC power supply rated at

2.25 W unless otherwise stated on the label.

!

The terminal may take as little as 100 mA in certain circumstances, so be

sure that the chosen power supply can operate correctly with this load.

Large switch-mode supplies tend to need a certain minimum load before

they will operate correctly.

In any case, it is very important that the power supply is mounted correctly if

the unit is to operate reliably. A very high proportion of reported problems are

caused by incorrect power supply installation, so please take care to observe the

following points...

!

The power supply must be mounted close to the unit, with usually not

more than 6 feet of cable between the supply and the PAPBH. Ideally, as

short a length as is possible should be used.

!

The wire used to connect the PAPBH’s power supply should be of at least

22 gauge wire. If a longer cable run is used, you should use a heavier

gauge wire. The routing of the cable should be kept away from large

contactors, inverters and other devices which may generate significant

electrical noise.

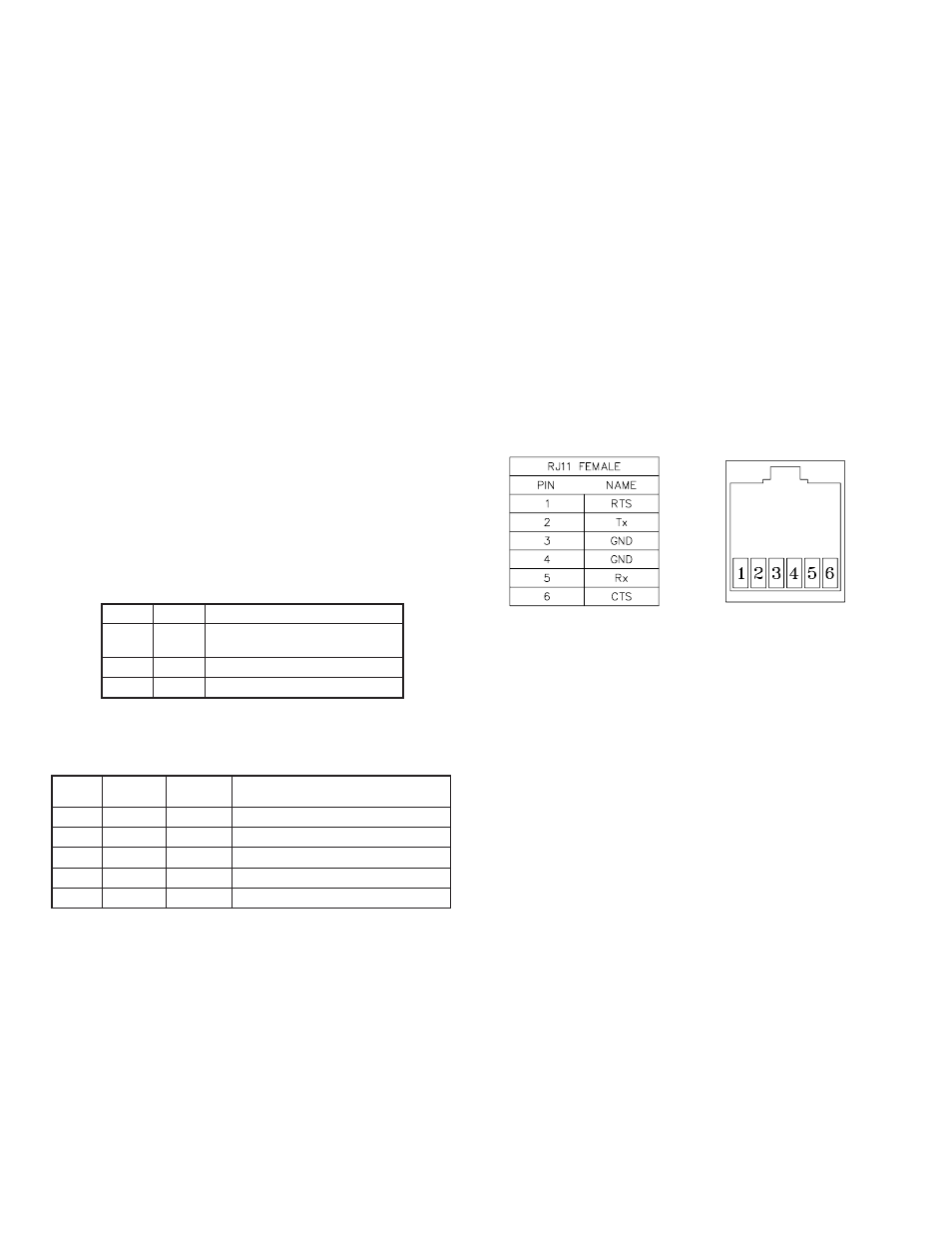

RS232 PORT PIN OUT

Both HMI and PC ports are RS-232 ports and have the same pin-out

described below. The following illustration and table gives the pin-out of these

ports to enable such connections to be made.

The above table denotes the pin names of the RS-232 port. When connecting,

the pin name at the port is connected to the opposite of that pin name at the

destination device.

PROFIBUS CONNECTION

It is recommended that PROFIBUS plug connector such as Siemens part

6ES7 972 – 0BA00 – 0XA0 be used. If the PAPBH is the last unit on the

network, set the terminating resistor switch to the “ON” position.

TROUBLESHOOTING

For further technical assistance, contact technical support at the appropriate

company numbers listed.

Immunity to EN 50082-2

Electrostatic discharge

EN 61000-4-2 Level 2; 4 Kv contact

Level 3; 8 Kv air

Electromagnetic RF fields

EN 61000-4-3 Level 3; 10 V/m

80 MHz - 1 GHz

Fast transients (burst)

EN 61000-4-4 Level 4; 2 Kv I/O

Level 3; 2 Kv power

RF conducted interference

EN 61000-4-6 Level 3; 10 V/rms

1

150 KHz - 80 MHz

Emissions to EN 50081-2

RF interference

EN 55011

Enclosure class A

Power mains class A

Rear View of Unit

NAME

COLOR

FUNCTION

DATA

Red

WD

Green

Watchdog State Machine State

DP

Red

DP Control State Machine State

DATA LED

(Red)

WD LED

(Green)

DP LED

(Red)

PARADIGM PROFIBUS HOST ADAPTER STATE

OFF

ON

OFF

Baud Search state

OFF

FLASHING

OFF

Baud Control State

OFF

OFF

ON

Waiting for Parameterization Telegram

OFF

OFF

FLASHING

Waiting for Configuration Telegram

ON

OFF

OFF

Data Exchange State

PROFIBUS-DP Data Exchange state

(driven by SPC3 DATA_EX pin)