Philips Saeco ESPRESSO SG200E User Manual

Page 50

50

English

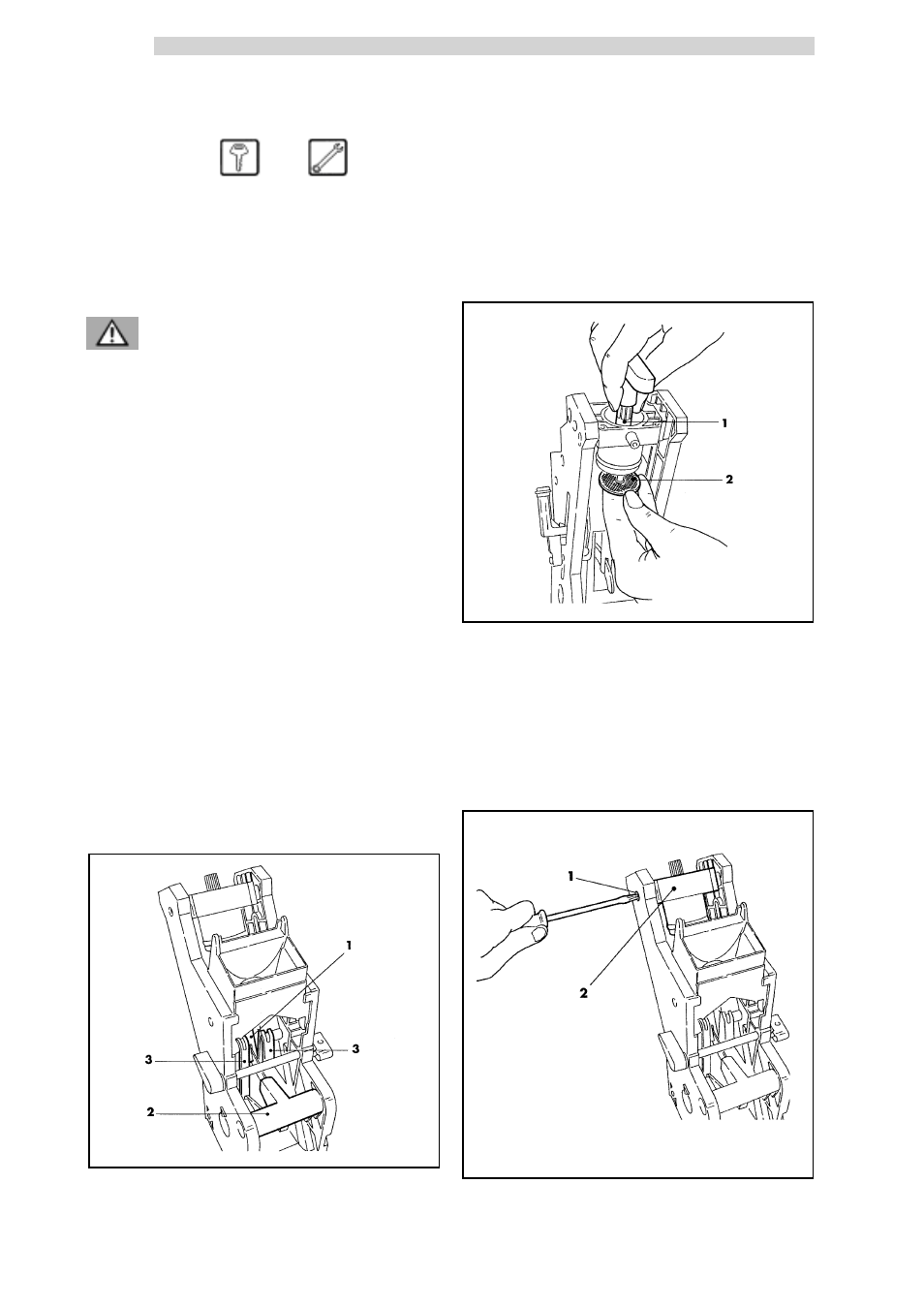

fig.54

fig.55

fig.56

9.2.1 Scheduled and unscheduled

maintenance

The operations described in this section are

intended as an example as they depend on

different variables, such as: water hardness,

humidity, products used, conditions and quantity

of work

Warning

Make sure the vending machine is off before

performing any operation requiring to

disassemble some of its parts.

Have the following operations performed by

qualified personnel only. If the operations are to

be performed with the machine on, choose

trained personnel.

More complex interventions, such as removing

limescale from the boiler, require a deep

knowledge of the machine.

Disinfect all the parts in contact with foodstuffs

using chlorine-based products on a monthly

base, as described in section 4.0.

9.2.2 Brew group maintenance

Plastic group. It is advisable to remove it and

rinse carefully with hot water on a monthly base;

every 5,000 strokes and, in any case, every

month all moving parts of the group must be

lubricated with silicon grease for food use (fig.54).

- lower filter rod (1).

- connecting rod (2)

- rails (3)

Replace gaskets and filters every 10,000

strokes.

- gaskets

Upper filter (fig. 55):

- loosen the upper pin (1) with the wrench

supplied with the machine.

- manually unscrew the filter (2).

Lower filter:

- unscrew the two side screws (ref. 1, fig. 56)

and remove the upper piston stop (2).