Adjusting for bottled gas, Adjusting for natural gas, Instructions for the installer – Smeg XXPTS725 User Manual

Page 9: 27 5.2 adjusting for bottled gas, 3 adjusting for natural gas

Instructions for the Installer

27

5.2

Adjusting for bottled gas

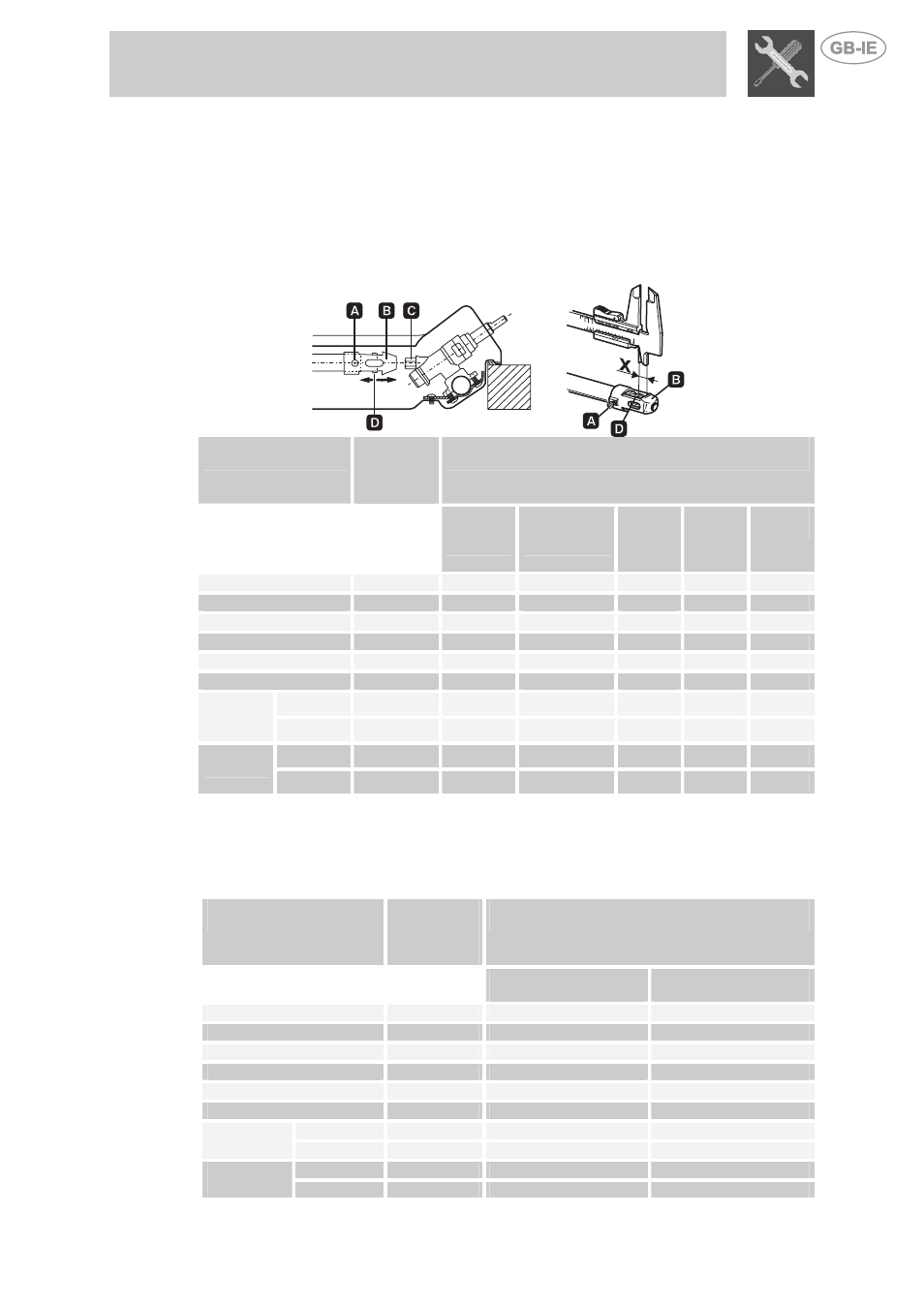

Undo the screw A and push the support B fully down. Remove the nozzle C with a

spanner and fit the suitable one following the instructions in the tables referring to the

type of gas to be used. The nozzle must not be tightened with a torque of more than 3

Nm. Return the support B to its original position, so that the nozzle C is perfectly

covered.

Burner

Nominal

heat

capacity

(kW)

Regulate the air flow by moving the Venturi pipe D until the distance “X” stated in point

"5.5 Adjusting the primary air flow” is obtained and secure it with the screw A. When the

adjustments are complete, restore the seals with wax or an equivalent material.

Bottled gas – G30/G31 30/37 mbar

Nozzle

diameter

1/100 mm

By-pass

mm

1/100

Reduce

d heat

capacity

(W)

Capacity

g/h G30

Capacity

g/h G31

Auxiliary

1.05

48

30

400

76

75

Semi rapid

1.7

62

33

500

124

121

Rapid (3)

3.5

89

50

1050

254

250

Rapid (7)

2.9

80

50

1050

211

207

Rapid (6)

3.1

85

50

1050

225

221

Ultra-Rapid

4.2

98

65

1600

305

300

Internal

0.9

45

30

400

62

61

Double

Crown (4)

External

3.3

87

55

1200

240

236

Internal

0.9

45

30

400

62

61

Double

Crown (8)

External

4.0

95

55

1200

291

286

5.3

Adjusting for natural gas

The appliance is tested with G20 (2H) natural gas at the pressure of 20 mbar. To return the

appliance to the condition required to use this type of gas, proceed as described in point “5.2

Adjusting for bottled gas” but select the nozzles and adjust the primary air flow for natural gas,

as indicated in the table below and in point “5.5 Adjusting the primary air flow”.

Burner

Nominal

heat

capacity

(kW)

Natural gas – G20 20 mbar

Nozzle diameter

1/100 mm

Reduced heat capacity

(W)

Auxiliary

1.05

132

400

Semi rapid

1.7

165

500

Rapid (3)

3.5

250

900

Rapid (7)

2.9

230

1.05

Rapid (6)

3.1

240

900

Ultra-Rapid

4.2

300

1100

Internal

0.9

126

400

Double

Crown (4)

External

3.3

250

1200

Internal

0.9

126

400

Double

Crown (8)

External

4.0

140

1200