Drill.press.rpm.chart drilling.depth, Operations – Woodstock THE SHOP FOX D2722 User Manual

Page 24

Use

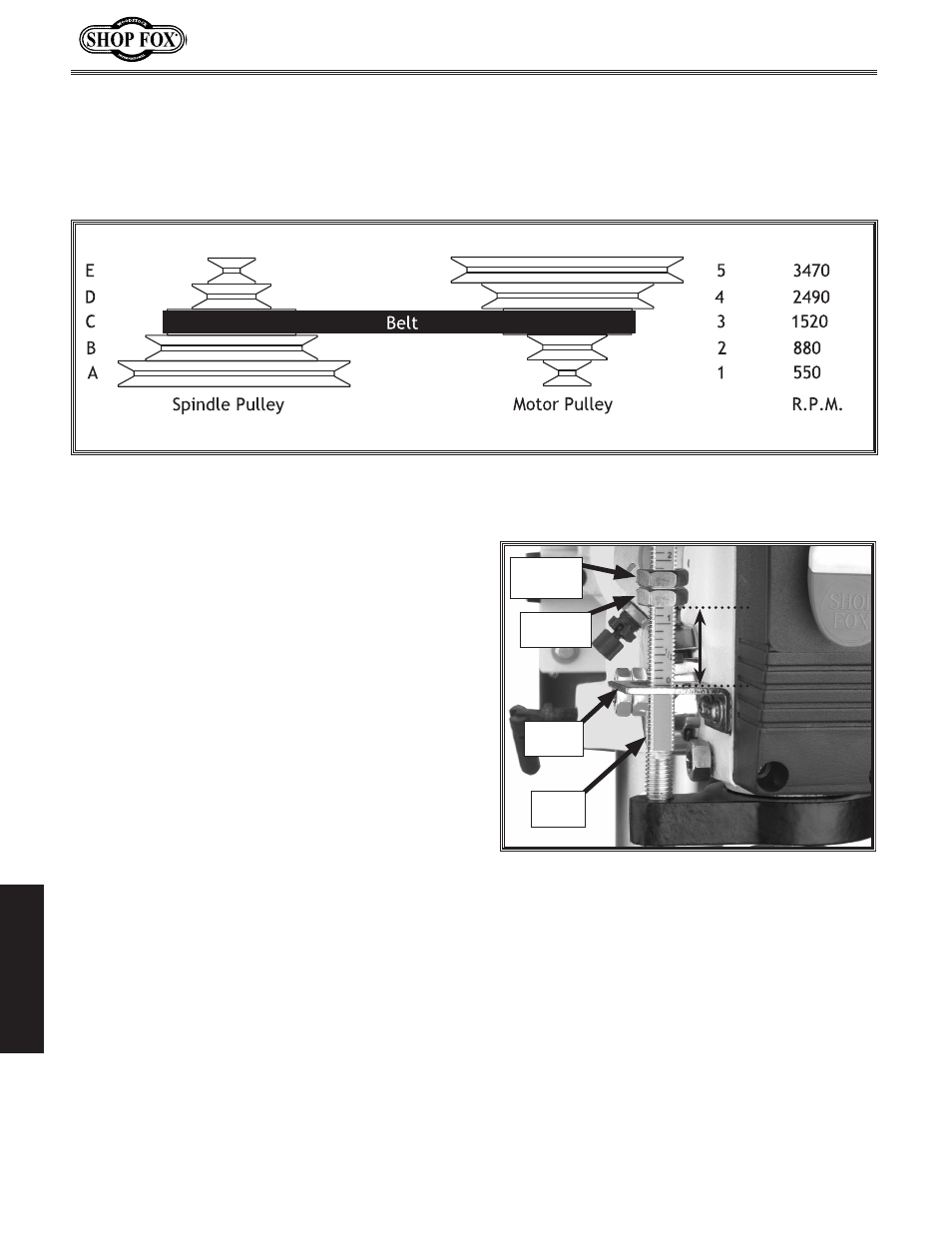

Figure.37.to select the optimum motor-to-spindle pulley ratio for drilling, cutting, and sanding

operations. for example the above figure shows the belt in the C position on the spindle pulley and the

#3 position on the motor pulley, which will give a speed of 1,520 RPM. Refer to the

Drill,.Cutter,.and.

Saw.RPM.Chart on Page.23 for suggested tool RPMs.

Figure.37..Drill Press RPM Chart.

Drill.Press.RPM.Chart

Drilling.Depth

Your new drill press comes fitted with a depth

stop that allows drilling many holes at a pre-

set depth consistently. When the hex nuts are

set, the nuts will contact the stop flange and

stop the drill press from drilling any deeper.

To.adjust.the.drilling.depth,.do.these.steps:

1. Measure the maximum depth that you want

to drill a series of holes at. In this example

the maximum depth is 1

1

⁄

4

" deep.

2. Loosen the hex nuts shown on the depth

stop and align the lower nut to the 1

1

⁄

4

"

mark on the depth stop rod (see

Figure.

38).

3. Hold the lower hex nut and tighten the

upper hex nut so both nuts are locked

together.

4. Make sure the depth has been set cor-

rectly, measure, or drill a hole into scrap

wood before drilling into any workpiece.

Figure.38..Depth stop set for 1

1

⁄

4

" drilling

depth.

Depth..

Stop

Upper

Hex Nut

Stop.

Flange

Lower.

Hex.Nut

1-1⁄4

"

OPERATIONS

-22-