Adjustments belt.tension, Adjustments – Woodstock THE SHOP FOX D2722 User Manual

Page 16

-14-

ADJUSTMENTS

Belt.Tension

During the life of your drill press you will use differ-

ent belt and pulley combinations. No matter which

pulley combination you use, make sure that the belt

is tensioned properly

To.adjust.the.drive.belt.tension,.do.these.

steps:

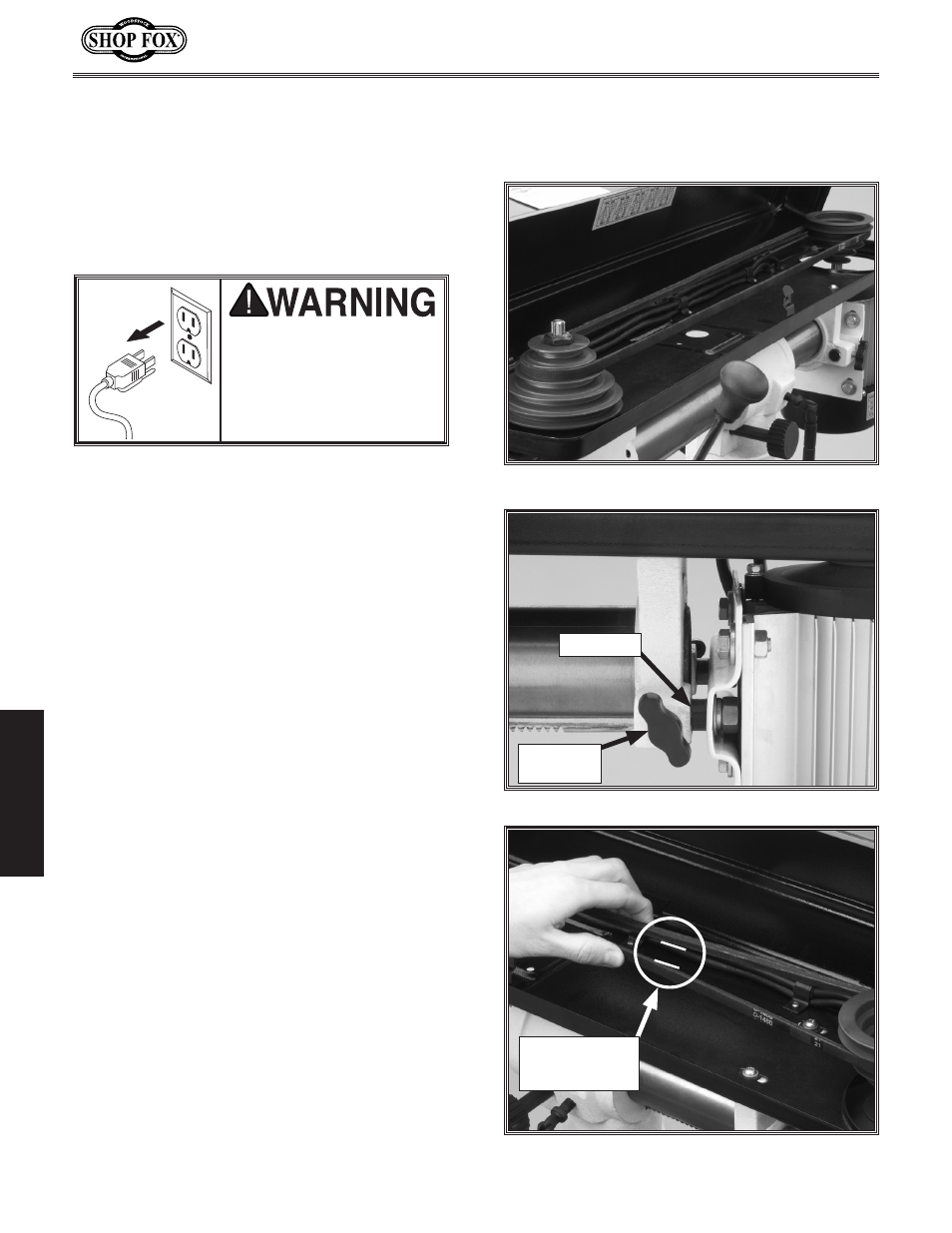

1... UNPLUG.THE.DRILL.PRESS!.

2... Open the belt safety cover (see Figure.

19).

3.. Loosen both motor lock knobs at the side

of the headstock (see

Figure.).

4... Slide the motor away from the headstock

until the belt is taut.

5... Hold the motor in position, and tighten the

lock screw, and make sure the belt deflec-

tion gap is correct when pinched together

between the pulleys (see

Figure.21).

• If the gap between both inner sides of

the belt is greater or less than

3

⁄

4

" repeat

Steps.3-5 until the deflection gap is

3

⁄

4

".

• If the deflection gap is

3

⁄

4

" the belt is ten-

sioned correctly.

6... Close the belt safety cover.

UNPLUG. the. drill. press..

before. any. assembly,.

adjustment,. maintenance,.

or. belt. changing. proce-

dures.. Otherwise. serious.

personal.injury.may.occur!

Figure.19..Open belt safety cover.

Figure.20..Motor lock knob.

Figure.21..Measuring belt deflection.

Motor

Lock Knob

Push rod

Belt Deflection

gap should be

about

3

⁄

4

"

ADJUSTMENTS