Pa rt s – Woodstock W1828 User Manual

Page 28

Model W1828 (For Machines Mfg. Since 4/11)

-26-

PA

RT

S

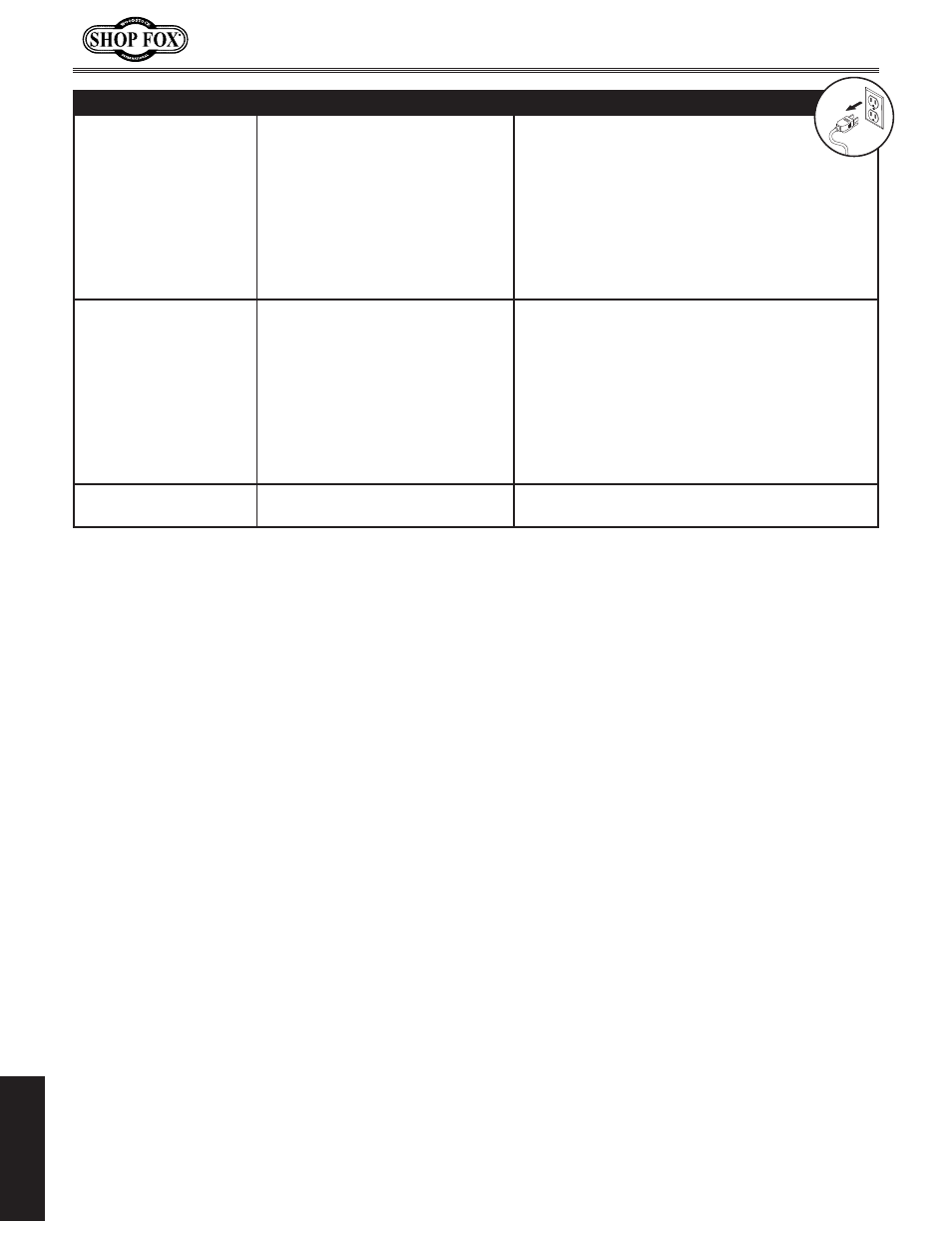

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Sandpaper clogs quickly or

burns.

1. Sandpaper grit is too fine for the

job.

2. Workpiece is too moist.

3. Sanding depth too aggressive.

4. Paint, varnish, pitch, or other coat-

ing is loading up sandpaper.

5. Sanding soft workpiece.

1. Replace with a coarser grit sandpaper.

2. Allow workpiece to dry out.

3. Reduce sanding depth or install coarser sandpaper.

4. Install a coarse grit sandpaper, or strip coating off

before sanding.

5. Use different stock. Or, accept the characteristics

of the stock and plan on cleaning/replacing discs

frequently.

Glossy spots, burning, or

streaks on workpiece.

1. Sandpaper too fine for the desired

finish.

2. Work held still for too long.

3. Workpiece is too moist.

4. Sanding stock with high residue.

5. Worn sandpaper.

6. Sanding depth too aggressive.

1. Use a coarser grit sandpaper.

2. Do not keep workpiece in one place for too long.

3. Allow workpiece to dry out.

4. Use different stock. Or, accept the characteristics of

the stock and plan on cleaning/replacing sandpapers

frequently.

5. Replace sandpaper.

6. Reduce sanding depth or install coarser sandpaper.

Abrasive rubs off easily.

1. Sandpaper has been stored in an

incorrect environment.

1. Store sandpaper flat and away from extremely dry,

hot, or damp conditions.