Service, General, Table/disc parallelism – Woodstock W1828 User Manual

Page 25

Model W1828 (For Machines Mfg. Since 4/11)

-23-

SE

RV

IC

E

SERVICE

This section covers the most common service adjustments

or procedures that may need to be made during the life

of your machine.

If you require additional machine service not included

in this section, please contact Woodstock International

Technical Support at (360) 734-3482 or send e-mail to:

General

MAKE SURE that your machine is

unplugged during all maintenance

procedures! If this warning is ignored,

serious personal injury may occur.

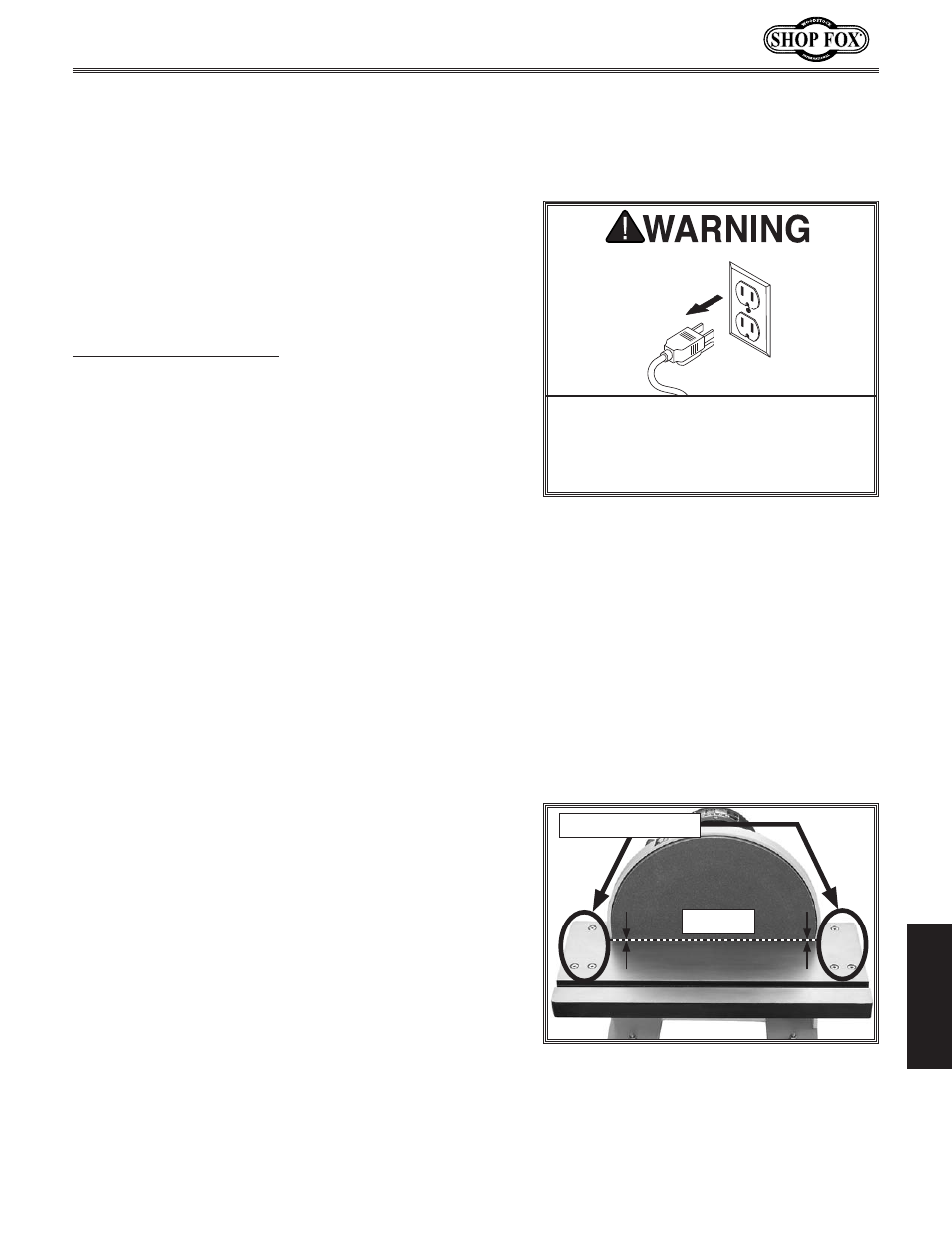

Table/Disc Parallelism

The edge of the table must be parallel with the face

of the sanding disc, and there should be a

1

⁄

16

'' gap

between the two. This gap should be large enough so that

the sandpaper does not rub against the table, but small

enough so that the gap is not a pinch hazard.

Tools Needed

Qty

Wrench 10mm ...................................................1

Phillips Screwdriver #2 .........................................1

Fine Ruler ........................................................1

To make the table and sanding disc parallel, do these

steps:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen the six flat head screws and hex nuts that

secure the table to the table support brackets.

3. Adjust the table so that there is a

1

⁄

16

'' gap (see

Figure 19) between the 12" disc (with sandpaper

installed) and the table, from left to right.

4. When the table is parallel with the sanding disc,

tighten the flat head screws and hex nuts.

5. Spin the disc by hand to make sure the sandpaper is

not touching the table.

— If the sandpaper does touch the table as you spin

the disc by hand, repeat

Steps 2–5 until it does

not.

6. Perform the Miter Gauge Calibration procedure

on the next page to ensure the miter slot is

perpendicular to the sanding disc.

Figure 19. Table parallel with sanding

disc.

1

⁄

16

" Gap

Flat Head Screws