Lubrication, Headstock – Southbend SB1014F User Manual

Page 62

-56-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

M A I N T E N A N C E

Lubrication

Headstock

Oil Type .. Mobil DTE Light or ISO 32 Equivalent

Oil Amount .............................................. 7.5 Liters

Check/Add Frequency .................................... Daily

Change Frequency ...................................Annually

The headstock lubrication system is the most

important lubrication system on the machine. It

consists of an electric oil pump, a low oil pressure

kill switch, a holding tank, oil lines, and a

distribution manifold. The headstock has a series

of oil lines that direct oil to key locations, such as

the spindle bearings and headstock gearing, to

ensure that they always remain well lubricated.

The oil pump automatically turns ON and begins

oiling the headstock components when the main

power switch is turned ON and the emergency

stop button is reset. The oil is pumped before the

spindle is started to protect the spindle bearings

against potential damage from dry starts.

Checking & Adding Oil

The sight glass on the side of the headstock oil

tank, shown in Figure 109, shows the oil level

and temperature; the bottom line represents the

minimum oil level and the top line represents the

maximum oil level. The lathe must be powered

down and stopped when to get an accurate

reading on the oil level.

When the oil level approaches the minimum line,

add enough oil to bring it up to the maximum

line.

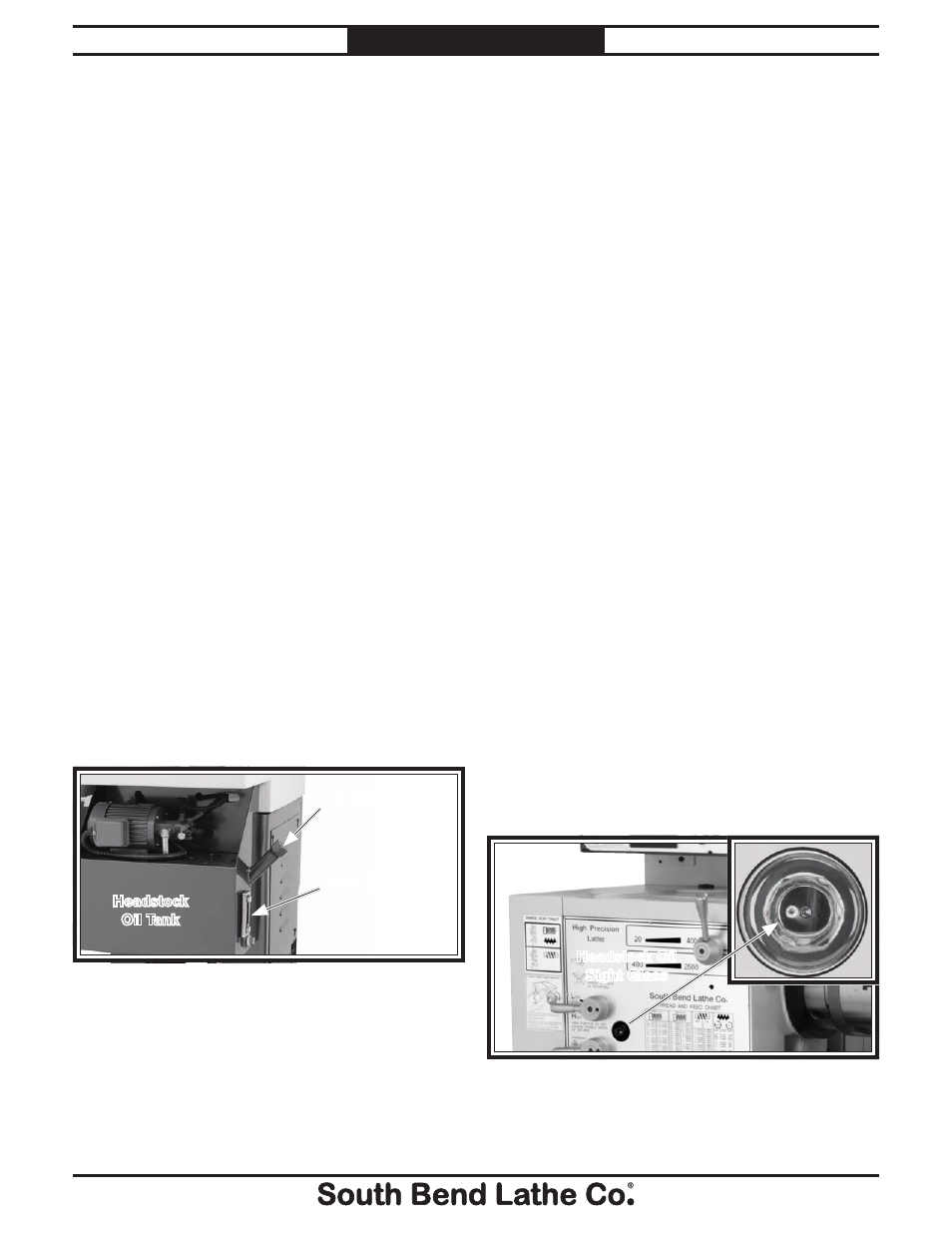

Figure 108. Headstock oil tank & components.

Sight Glass

Headstock

Oil Tank

Oil Fill Spout

Monitoring Oil Temperature

During operations, regularly monitor the oil

temperature shown in the sight glass in Figure

109. The temperature of the headstock oil must

remain under 170° F. or the oil will start to

overheat and break down, causing it to lose its

lubrication properties.

Under normal conditions, the oil should not

reach 170° F.; however, if it does, shut down the

machine and allow the oil to cool. Investigate

why the oil is getting so hot. Possibilities may

be poor ventilation, excessive work loads, poor

oil quality, oil is breaking down (losing lubricity)

due to long term use, or extreme work site

temperatures.

If possible, correct the conditions causing the

oil to get hot. If the oil is old or you suspect it is

of poor quality, change it. If the work loads or

working environment are extreme, reduce the

duty cycle of the lathe to allow the oil to cool

down when it gets hot.

If the oil temperature ever exceeds 170° F.,

change it as soon as possible to make sure the

spindle bearings have high quality lubrication.

Verifying Oil Pump Operation

To prevent costly damage to the headstock gears

and bearings, a kill switch will shut the lathe

down if the oil pump stops working or the oil

level is too low. You can verify that the pump is

working by looking at the sight glass shown in

Figure 109. When working correctly, oil can be

seen flowing across the sight glass.

Figure 109. Location of the headstock oil sight glass.

Headstock Oil

Sight Glass