Chuck & faceplate mounting, Removing chuck or faceplate – Southbend SB1014F User Manual

Page 33

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

-27-

O P E R A T I O N

Chuck & Faceplate

Mounting

This lathe is shipped with the 3-jaw chuck

installed. This is a scroll-type chuck, meaning

that all three jaws move in unison when

adjusted.

The included 4-jaw chuck features independent

jaws, which are used for square or unevenly-

shaped stock, and to mount work that needs to

be adjusted to near "0" total indicated runout.

If neither chuck can hold your workpiece, the

cast-iron faceplate has slots for T-bolts that hold

standard or custom clamping hardware. With the

correct clamping hardware, this faceplate will

hold non-cylindrical parts.

The chucks and faceplate have a D-6 camlock

mount. A chuck key is used to turn the locking

cams (Figure 40) to secure/release the chuck/

faceplate.

Items Needed

Qty

Dead Blow Hammer .............................................. 1

Chuck Cradle or Plywood

3

⁄

4

" (to protect bed) ...... 1

Chuck Key ............................................................. 1

Removing Chuck or Faceplate

1.

DISCONNECT LATHE FROM POWER!

2.

Lay a chuck cradle (see Figure 39) or

plywood under the chuck or faceplate and

over the bedway to protect the precision

ground surfaces from damage and reduce

injury if fingers get pinched.

Figure 39 Wooden chuck support cradle.

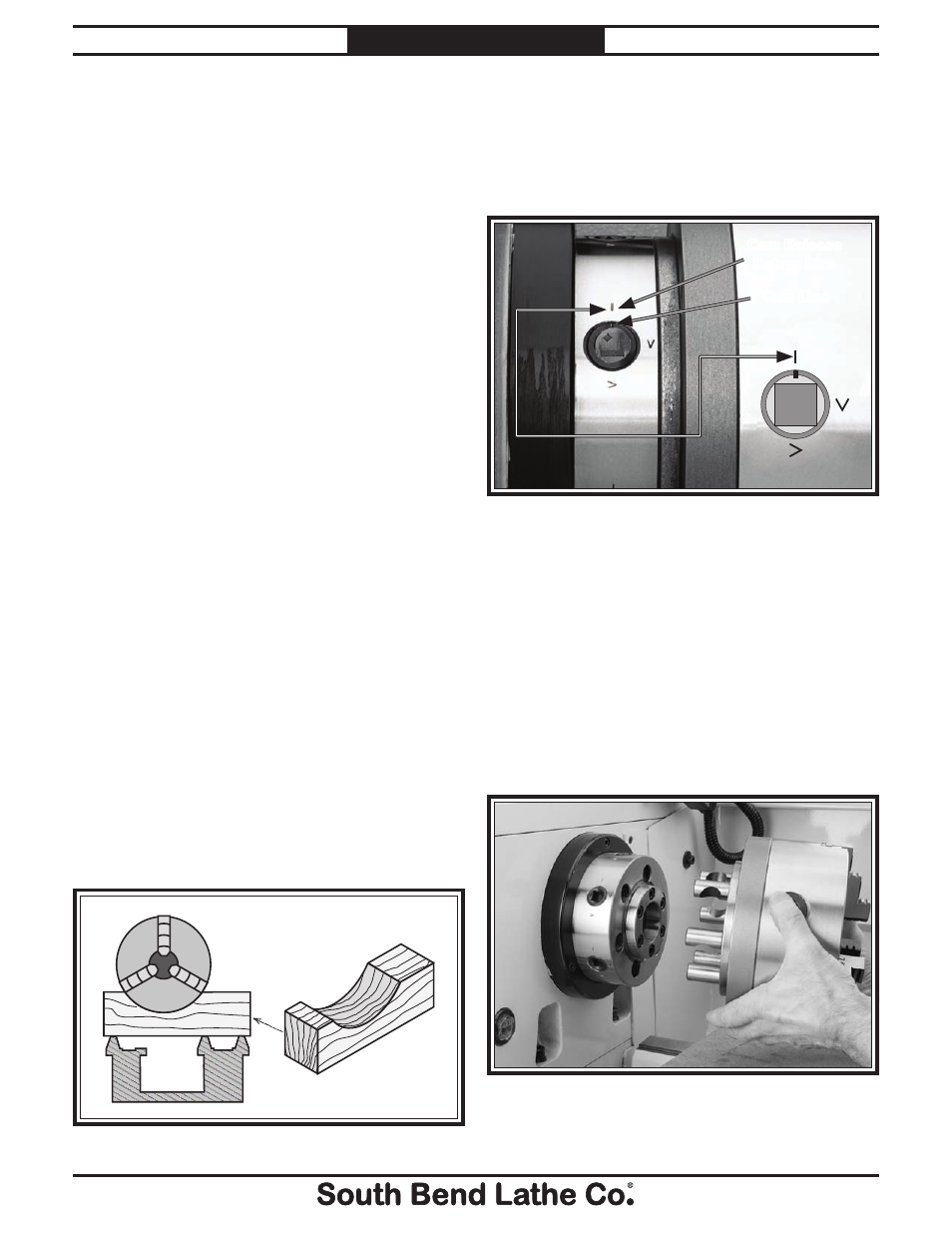

3.

One at a time, use the chuck key to turn

each of the camlocks counterclockwise until

the cam line aligns with the cam release

datum line, as shown in Figure 40. As you

turn the camlocks, they will rise up slightly

from the spindle body.

Figure 40. Camlock loosened with the cam line

aligned with the datum line.

Cam Line

Cam Release

Datum Line

4.

Remove the chuck key, then use a dead-

blow hammer or a wood block to lightly tap

around the circumference of the chuck or

faceplate to break it free from the spindle

taper and camlock sockets. Be sure to

support the bottom of the chuck.

5.

With a rocking motion, carefully remove the

chuck or faceplate from the spindle nose, as

shown in Figure 41, making sure to support

the weight with an adequate chuck cradle.

Figure 41. Example of removing a 3-jaw chuck from a

spindle nose.