Recommended adjustments – Southbend SB1014F User Manual

Page 28

-22-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

P R E P A R A T I O N

7.

After completing the previous step, stop the

spindle and move the gearbox range lever to

neutral, then move the spindle speed range

lever to high.

8.

Turn the lathe ON and let it run for ten

minutes in each speed of 400, 1000, and 2500

RPM.

9.

After

completing

Step 8, reduce the spindle

speed to 400 RPM and let the lathe run for a

final 15 minutes as a cool-down.

10.

Turn the lathe OFF.

11.

Change the oil in all of the reservoirs,

tighten the V-belts, and perform all

other lubrication steps mentioned in the

Maintenance section of this manual.

For your convenience, the adjustments listed

below have been performed at the factory.

However, because of the many variables involved

with shipping, we recommend that you at least

verify the following adjustments to ensure the

best possible results from your new machine.

Step-by-step instructions for these adjustments

can be found on the pages referenced below.

Factory adjustments that should be verified:

s

4AILSTOCK

s

#OMPOUND

s

'IB

Recommended

Adjustments

After the first 16 hours of use, the V-belts will

stretch and seat into the pulley grooves. The

V-belts must be properly re-tensioned after

this period to avoid reducing their useful life.

Refer to the V-Belts section on Page 69 for

detailed instructions.

5.

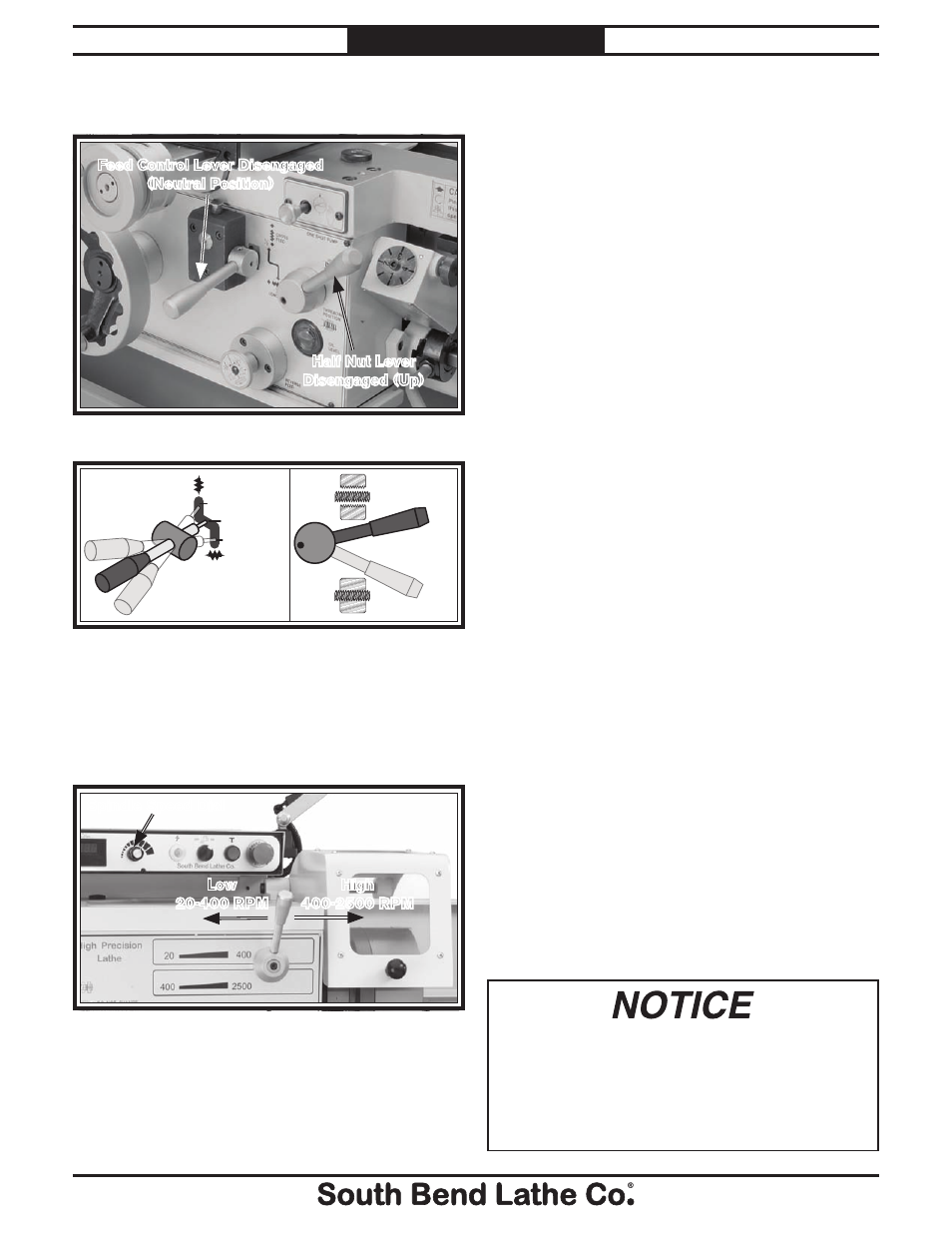

Disengage the half nut and the feed control

levers shown in Figures 30–31.

Figure 30. Power fed and half nut levers disengaged.

Half Nut Lever

Disengaged (Up)

Feed Control Lever Disengaged

(Neutral Position)

6.

Turn the lathe ON, and let it run for ten

minutes in each speed of 20, 200, and 400

RPM, using the spindle speed dial (Figure

32) to adjust the speed.

Figure 32. Spindle speed controls.

Low

20-400 RPM

High

400-2500 RPM

Spindle Speed Dial

Figure 31. Feed control lever and half nut in

disengaged positions.

Engaged

HALF NUT

LEVER

Disengaged

Cross Slide

Neutral

FEED CONTROL

LEVER

Carriage