Guidelines for special print media – Samsung ML-1630W Series User Manual

Page 34

4

.4

Guidelines for special print media

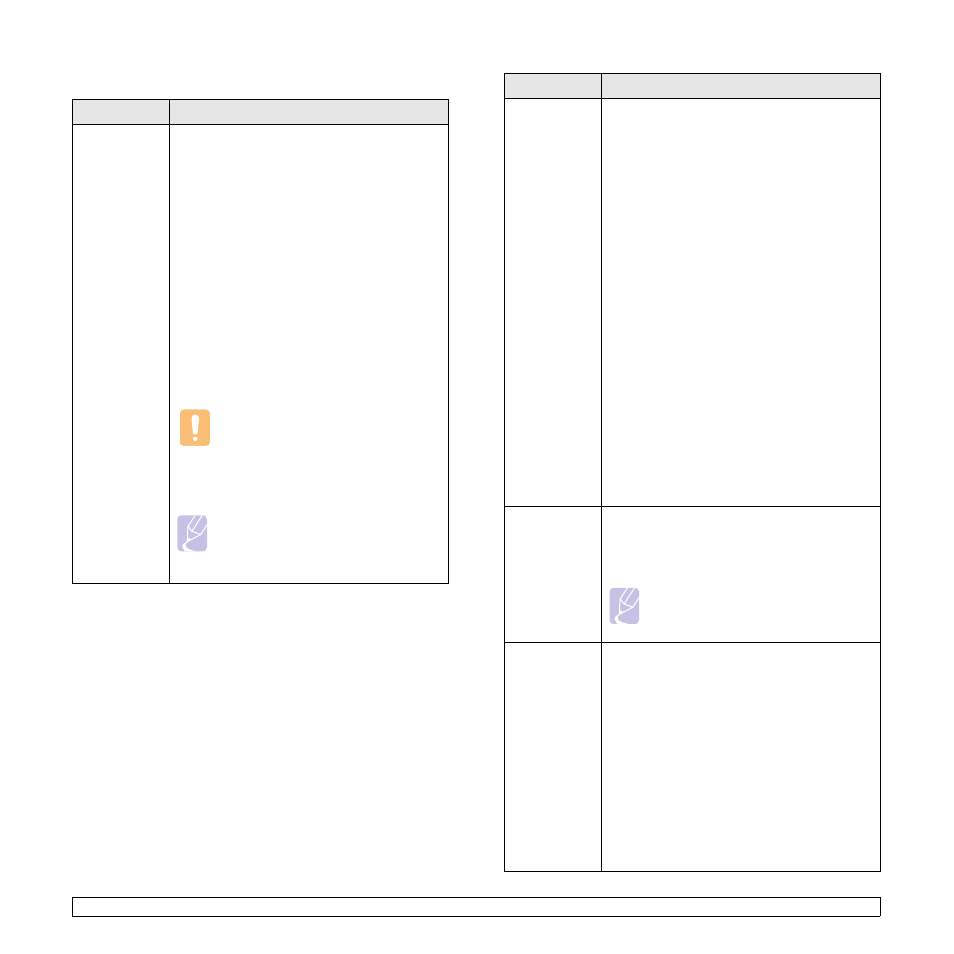

Media type

Guidelines

Transparencies

• To avoid damaging the machine, use only

transparencies designed for use in laser

machines.

• Transparencies used in the machine must be

able to withstand the machine’s fusing

temperature. Check your machine’s specification

to view the fusing temperature, see page 9.1.

• Place them on a flat surface after removing them

from the machine.

• Do not leave them in the paper tray for long

periods of time. Dust and dirt may accumulate

on them, resulting in spotty printing.

• To avoid smudging caused by fingerprints,

handle them carefully.

• To avoid fading, do not expose printed

transparencies to prolonged sunlight.

• Ensure that transparencies are not wrinkled,

curled, or have any torn edges.

Caution

Recommended media: Transparency for a

Color Laser Printers produced by HP,

Xerox and 3M. It is not recommended to

use paperbacked transparencies such as

Xerox 3R91334, which can cause a jam or

be scratched.

Note

If your machine does not feed the

transparency print media properly, put a

blank sheet of paper under the

transparency, and try again.

Labels

• To avoid damaging the machine, use only labels

designed for use in laser machines.

• When selecting labels, consider the following

factors:

- Adhesives: The adhesive material should be

stable at your machine’s fusing temperature.

Check your machine’s specification to view the

fusing temperature, see page 9.1.

- Arrangement: Only use labels with no

exposed backing between them. Labels can

peel off sheets that have spaces between the

labels, causing serious jams.

- Curl: Prior to printing, labels must lie flat with

no more than 13 mm of curl in any direction.

- Condition: Do not use labels with wrinkles,

bubbles, or other indications of separation.

• Make sure that there is no exposed adhesive

material between labels. Exposed areas can

cause labels to peel off during printing, which

can cause paper jams. Exposed adhesive can

also cause damage to machine components.

• Do not run a sheet of labels through the machine

more than once. The adhesive backing is

designed for only a single pass through the

machine.

• Do not use labels that are separating from the

backing sheet or are wrinkled, bubbled, or

otherwise damaged.

Card stock or

custom-sized

materials

• Do not print on media smaller than 105 mm wide

or 148 mm long.

• In the software application, set margins at least

6.4 mm away from the edges of the material.

Note

If you experience jams with card stock

feeding, turn the paper around and try

again.

Preprinted

paper

• Letterhead must be printed with heat-resistant

ink that will not melt, vaporize, or release

hazardous emissions when subjected to the

printer’s fusing temperature for 0.1 second.

Check your machine’s specification to view the

fusing temperature, see page 9.1.

• Letterhead ink must be non-flammable and

should not adversely affect printer rollers.

• Forms and letterhead should be sealed in a

moisture-proof wrapping to prevent changes

during storage.

• Before you load preprinted paper, such as forms

and letterhead, verify that the ink on the paper is

dry. During the fusing process, wet ink can come

off preprinted paper, reducing print quality.

Media type

Guidelines