Troubleshooting, Se rv ic e – Woodstock W1815 User Manual

Page 29

-27-

Model W1815 (Mfg. Since 10/10)

SE

RV

IC

E

Troubleshooting

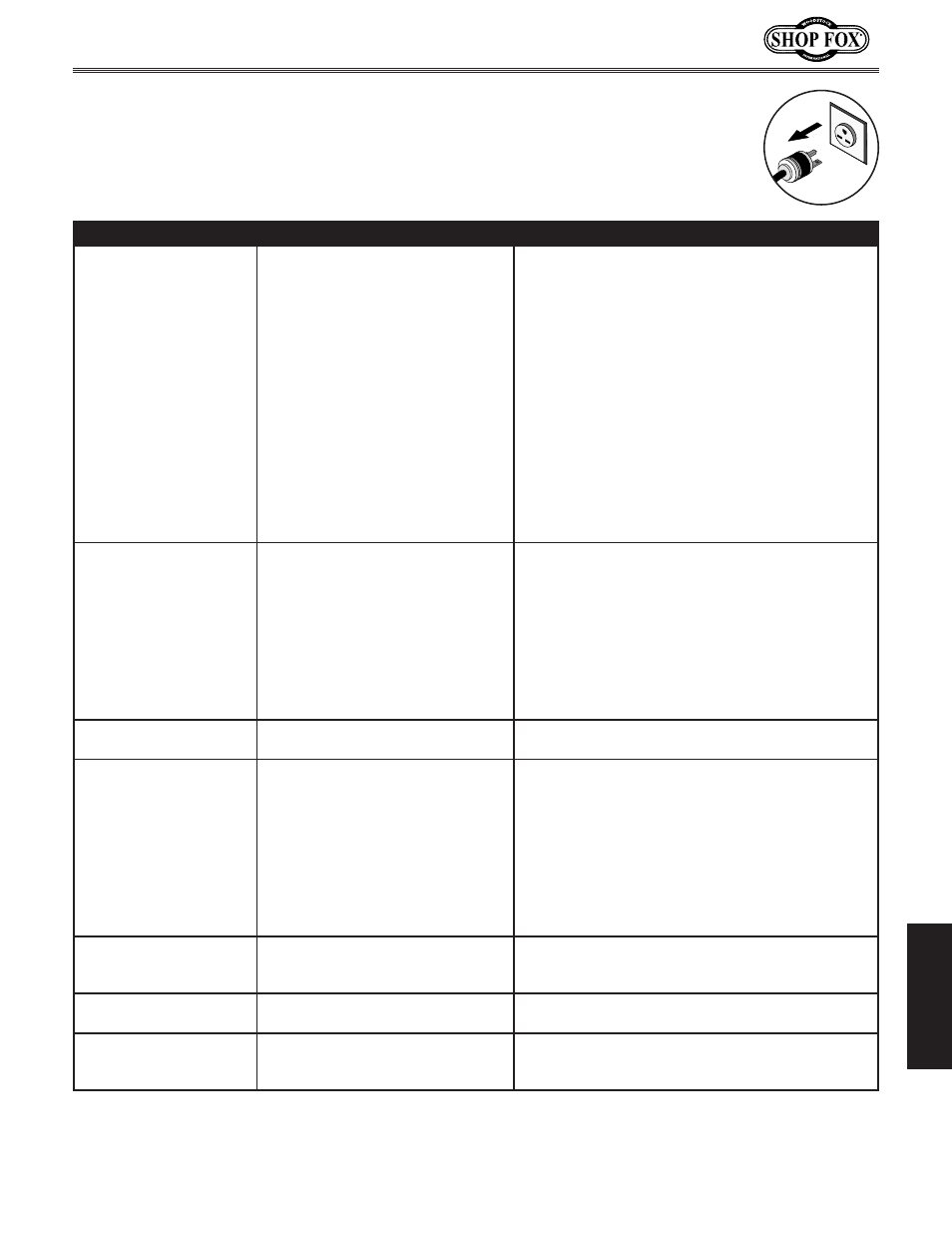

This section covers the most common problems and corrections with this type of

machine.

WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Motor will not start or is

slow to start.

1. Switch disabling key removed.

2. Break or short in wiring, loose

connections, plug or receptacle is

corroded or miswired.

3. Power supply switched off/has

incorrect voltage.

4. Blown fuse/tripped circuit breaker

at main panel.

5. Motor

connection

wired

incorrectly.

6. Motor ON/OFF switch at fault.

7. Motor brake not disengaging.

8. Start capacitor has blown.

9. Centrifugal switch at fault.

10. Motor at fault.

1. Re-install switch disabling key.

2. Trace/replace broken or corroded wires, fix loose

connections, correct wiring.

3. Switch power supply on/verify voltage.

4. Correct the cause of overload, then reset/replace

fuse or breaker.

5. Wire motor correctly (refer to inside junction box

cover or manual).

6. Replace switch.

7. Test to see if disc spins freely. If it drags, replce

motor brake and regulator.

8. Test/replace if at fault.

9. Adjust/replace centrifugal switch.

10. Test for shorted windings or bad bearings; repair or

replace.

Machine has excessive

vibration or noise.

1. Workpiece loose or incorrectly

secured.

2. Motor fan rubbing on fan cover.

3. Motor mounting loose.

4. Lock lever is loose.

5. Machine incorrectly mounted to

cabinet.

6. Motor bearings worn or damaged.

1. Use correct holding fixture and re-clamp

workpiece.

2. Fix/replace fan cover; replace loose or damaged

fan.

3. Tighten mounting bolts/nuts; use thread locking

fluid.

4. Tighten the lock lever.

5. Level/shim base; tighten/adjust mounting hardware

or feet.

6. Replace motor bearings or motor.

Motor overheats.

1. Motor brake not releasing.

1. Test to see if sanding disc spins freely. If not, replace

motor brake and regulator.

Machine stalls or slows

when operating.

1. Too much pressure when feeding

workpiece

2. Workpiece is warped.

3. Workpiece is incorrect for

machine.

4. Motor

connection

wired

incorrectly.

5. Motor overheated.

6. Centrifugal switch at fault.

7. Motor at fault.

1. Reduce pressure when feeding workpiece.

2. Straighten workpiece or use a different one.

3. Only sand wood and ensure moisture is below 20%.

4. Review wiring diagram on motor cover; correct wire

connections.

5. Let cool, clean motor, and reduce workload.

6. Adjust/replace centrifugal switch if available.

7. Test, repair, or replace motor.

Motor takes longer than

7 seconds to stop sanding

disc.

1. Motor brake components at fault.

1. Replace motor brake components. Call Tech Support

if you need assistance.

Miter bar binds in miter

slot.

1. Miter slot dirty or gummed up.

1. Carefully clean miter slot.

Workpiece angle incorrect

or out of square.

1. Pointer or scale not calibrated

correctly. Miter gauge or table not

correctly aligned.

1. Adjust pointer or scale to reflect real path of cut.