Pt2000 pressure roller system description – Graco Inc. 223660 User Manual

Page 5

5

307-730

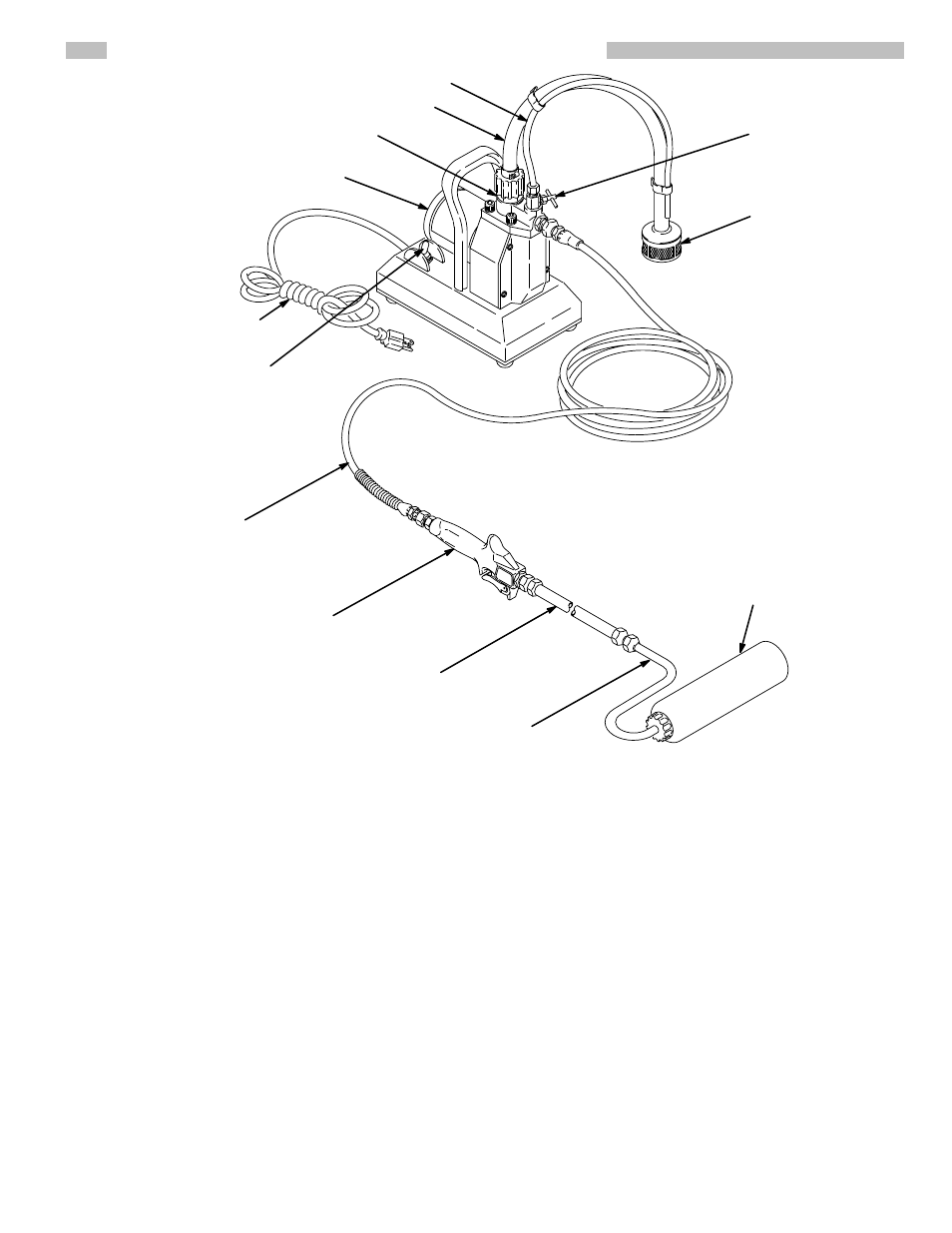

PT2000 PRESSURE ROLLER SYSTEM DESCRIPTION

SUCTION HOSE

PRIMING TUBE

INLET VALVE

MOTOR

ON/OFF SWITCH

POWER SUPPLY CORD

ROLLER VALVE

PRIMING VALVE

PAINT FILTER

25 FT. (7.6 M) HOSE

18 INCH EXTENSION

9 INCH ROLLER FRAME

ROLLER COVER

0285

Motor

The motor drives the connecting rod which moves the

diaphragm.

Pressure Switch

The pressure switch at the pump outlet turns the motor

on and off to control paint pressure.

Diaphragm

The diaphragm is the heart of the pump. Driven by the

connecting rod and motor , the movement of the dia-

phragm draws paint through the suction hose and to the

outlet valve.

Priming Valve

The priming valve assists in priming the pump during

startup. Turning the priming valve

counterclockwise

causes the paint to drain directly back into the pail

through the priming tube. T urning the knob

clockwise

causes the paint to flow through the fluid outlet valve and

to the hose, roller valve and extension.

Outlet Valve

The outlet valve has a ball check which prevents paint

from flowing backwards into the pump. This helps keep

an even supply of paint to the roller each time you trigger

the roller valve.

Inlet Valve

As the diaphragm draws paint from the suction tube, the

paint passes through the inlet valve which opens to allow

paint into the pump.

Outlet Hose

The hose has swivel-type couplings for easy assembly.

A larger diameter outlet hose and chemical-resistant out-

let and suction hoses are available. See ACCESSORIES

on page 19.

Roller Valve

The roller valve controls paint flow to the roller by trigger-

ing it on and off.

Pressure Roller

The pressure roller has an 18 inch extension. Two roller

covers, one 1/2 inch nap for smooth surfaces, and one

3/4” nap for semi–rough surfaces, are provided. Different

lengths and adjustable extensions and different types of

roller covers are available. See ACCESSORIES on page

19.