Hold-down adjustment, Blade adjustment – Grizzly FOOT SHEAR T23036 User Manual

Page 18

-16-

t23036 37" Foot Shear

Hold-Down

Adjustment

the hold-down functions as a safety device to

secure the workpiece while it is being sheared

and to help prevent the operator's fingers from

getting in the blade cutting path. the hold-down

must be adjusted properly to perform these func-

tions.

the ideal adjustment provides only enough clear-

ance to slide the workpiece under the workstop.

For practicality and safety, the workstop should be

adjusted to provide approximately

1

⁄

8

" clearance.

items Needed

Qty.

Stock

1

⁄

8

" .............................................................1

Socket or Wrench 19mm ....................................1

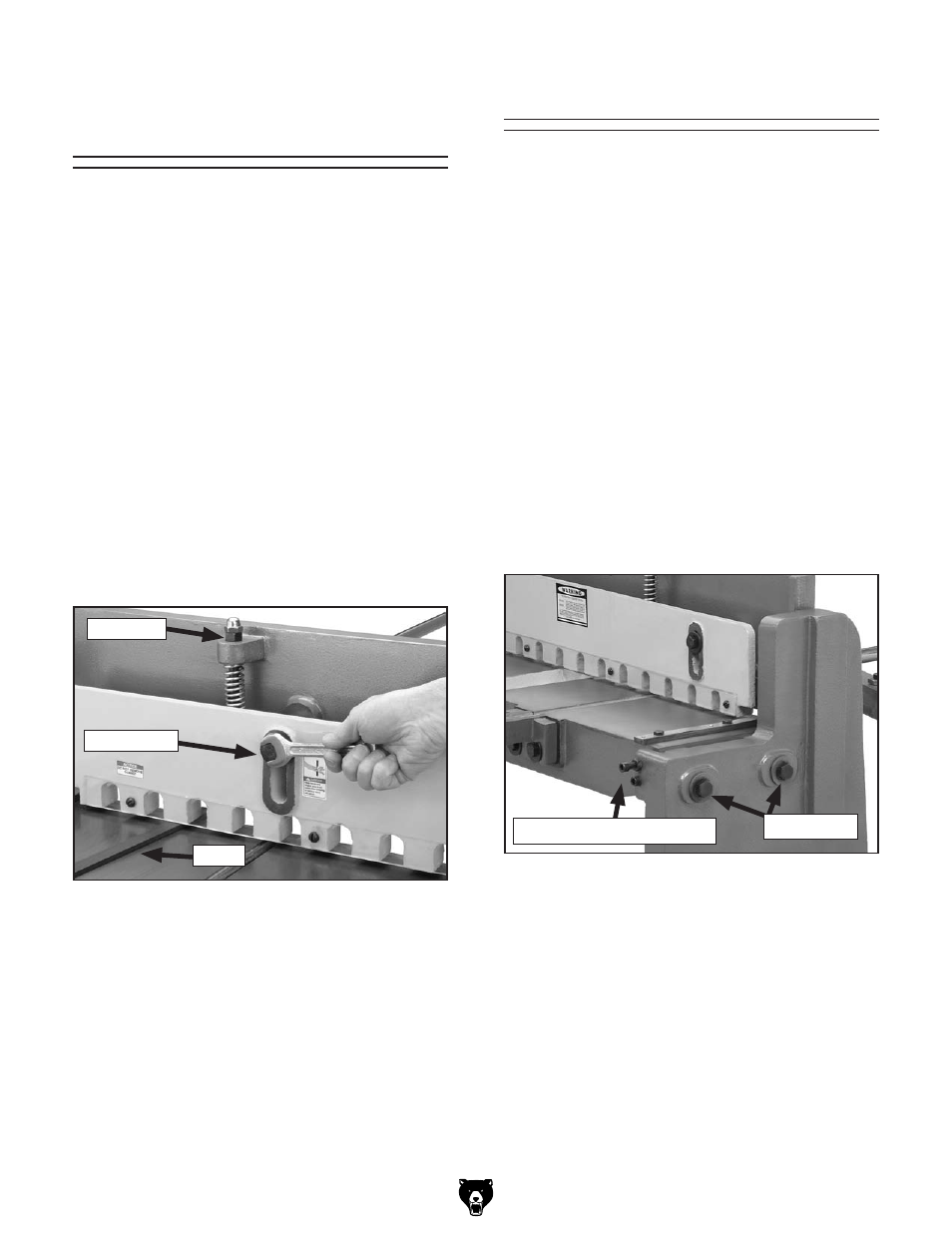

To adjust the hold-down:

1. tighten the hex nuts on the springs to raise

the hold-down off the table (

Figure 17).

Figure 17. tightening hold-down.

hex nut

Fixing Bolt

Shim

2. insert the shim stock under the hold-down,

then loosen the hex nut to lower the hold-

down until it makes contact with the shim.

3. repeat Step 2 at the other side of the shear.

4. Check the gap to make sure the distance is

equal across the length of the hold-down.

Tip: To avoid scratching the surface of your

workpiece, apply thin rubber pads to the bottom

of the hold-down fingers.

the blade adjustment has been made at the fac-

tory before shipment. A few test cuts will deter-

mine if this adjustment is satisfactory for your

needs. if it is, you are ready to start using your

foot shear. however, you may find it necessary

to check the blade adjustment before continuing.

depending on how often you change the type

and gauge of material you cut, this adjustment

process may become routine.

Tools Required

Qty.

Socket or Wrench 24mm ....................................1

hex Wrench 8mm ...............................................1

Feeler gauge 0.002" ..........................................1

To perform the blade adjustment:

1. loosen, but do not remove the two table bolts

and table adjustment screws on both sides of

the foot shear (see

Figure 18).

blade Adjustment

Figure 18. Adjustment screws.

table Bolts

table Adjustment Screws

2. Using the foot pedal, lower the blade and

hold it in position. (it may help to have your

assistant do this step.)

3. turn the table adjustment screws to move

the table and fixed blade until the fixed blade

makes light contact with the moving blade.

NOTICE: The moving blade should never

overlap the fixed blade. This will cause dam-

age to both.